Generative AI was the hot topic at the 2023 Advantech Industrial IoT World Partner Conference, October 26-28, 2023, in Taipei, Taiwan. Image courtesy of Advantech.

The tagline Enabling an Intelligent Planet might spur the question: What does “intelligent” mean? And in the context of IIoT, how does a factory become intelligent?

According to Willie Lin, director of iFactory Solutions and WISE-IoT at Advantech (whose company uses this tagline), an intelligent factory features two things.

First is the knowledge and understanding of what’s happening in the factory, which requires sensors to gather information. The second is problem-solving — using knowledge to quickly identify and solve problems. Most factories have knowledgeable people who can extract information, make sense of it, and devise solutions based on experience. But as these workers retire, change jobs, and leave companies, transferring experience-based information is challenging.

“We need to record this kind of knowledge so that no matter how staffs change, it can be transferred to other people, and they can immediately solve problems,” said Lin. Data from sensing, operator knowledge, and problem-solving power what make intelligent factories different, he added.

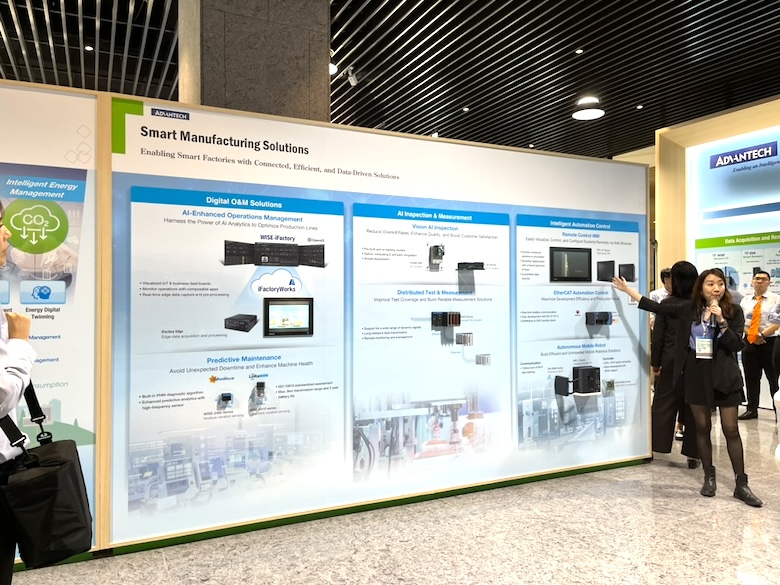

Advantech aims to boost manufacturing intelligence through its iFactory solutions.

The second feature that defines an intelligent factory is the use of AI to boost functional capabilities and reduce the time it takes to digitally transform its operations. That’s true with any combination of people, machines, processes, or software. Lin notes that digital transformation is typically associated with people’s learning curves, even for basic tasks such as where to click on a screen to start an application. He predicts that generative AI will change that learning curve and shift the cognitive load onto AI chatbots.

“With generative AI, no matter how you transfer from different software, you will use chatbots to get answers. Maybe not now, but in 10 years, I think that will change the way we control devices, the way we control machines, and the way we get answers … and that will hasten digital transformations,” said Lin.

But Lin doesn’t think that AI will replace people, so there’s no risk in removing reliance on human experience.

“You’re not using AI to repress a human; you are using it to make smarter decisions,” said Lin. “We are using this technology to make things better and make decisions faster. I don’t think AI will replace people, but it will make them smarter. That’s what I see in the next generation.”

Magic Pao, AVP of Advantech’s Industrial Cloud & Video Group, notes that AI is like accelerated computing and can’t be pushed into factories to increase adoption. Instead, it needs to impress the end user first.

“When we talk to end users, they always ask, ‘How does the solution help me complete my job and make my life easier?’ It’s an ongoing discussion,” said Pao.

Pao recently visited one U.S. warehouse to learn how the company implements certain technologies. The warehouse reported that slightly adjusting camera positions trimmed seconds off every barcode scan. That may sound trivial, but when scanning millions of packages each year, the seconds add up quickly and save significant time to boost facility throughout. In fact, initial AI implementations are often small and seemingly trivial but can make huge impacts over the long term.

EdgeLink integrates OT and IT and integrates legacy devices into IoT systems.

After improving efficiency, Pao says the next step is to use generative AI to increase safety.

“Right now, we still see lots of facility personnel being injured. One solution is to use machine vision to monitor behaviors and stop workers, robots, or machinery as needed to avoid injuries. Of course, that relies on connectivity,” said Pao. Here, both wireless connectivity and very low-latency connectivity are paramount to ensuring immediate equipment response to an instruction to stop, Pao added.

In two or three years, Pao believes factories will be able to implement real intelligence beyond simply collecting information from sensors to display on dashboards. He says operators will be able to use generative AI to answer factory status questions and communicate with robots in more humanlike ways.

As such, David Jen, AVP and head of Advantech’s Intelligent System Group, encourages users to view generative AI technology as a coworker — someone (or something) providing information that workers would otherwise need to search for proactively. It’s more of a collaboration between a worker and the technology. He notes that humans make mistakes and are influenced by emotions and external factors, such as the weather, which can vary worker performance. That’s when our AI coworker intervenes.

“IoT data-driven applications with generative AI will facilitate efficiency, especially for production manager decisions,” said Jen. “Besides data, it’s all about image and video.”

For example, AI can expedite notifications when images or videos show anomalies, especially for safety purposes. Instead of capturing video and waiting for a human to notice an anomaly or problem and then notify others, the AI can “watch” the video continuously and alert workers immediately.

One challenge, however, is creating AI models for different cultures around the world — or even for different factories within a state or province.

“You can’t generate one AI model and deploy it worldwide,” said Jen. “Different countries and different cultures will change the AI model because of different behavior. That’s why we collaborate with domestic partners in Europe, the U.S., and China, for example.”

The 2023 Advantech Industrial IoT World Partner Conference was evidence of such collaboration. IIoT professionals from more than 300 companies worldwide convened October 26-28, 2023, in Taipei, Taiwan, to discuss trends and projections — and Artificial Intelligence of Things (AIoT) took center stage.

Linda Tsai shared Advantech’s strategy for advancing digitalization with AIoT. Image courtesy of Advantech.

“We see that there are many implementations going on to digitalize factories with AIoT,” said Jash Bansidhar, managing director of Advantech Europe and AVP of Industrial IoT. “To give you some facts, 50% of the manufacturing industry in Europe is implementing AIoT to modernize their facilities, increasing quality management, asset tracking, monitoring, as well as managing inventory.”

Bansidhar also noted that it’s already been a decade since the global adoption of Industry 4.0 and digital transformations in manufacturing. Though smart factories remain at the center, adjacent sectors such as warehousing, smart grids, and transportation directly contribute to the Industry 4.0 ecosystem, as evidenced by certain suppliers’ sector-driven product lines. Adding AI to these ecosystems enables even more possibilities.

“We believe that with the integration of AI, digitalization, edge management and orchestration, and security, we can make a new edge era,” said Linda Tsai, president of Industrial IoT at Advantech. “People think that AI is in proof-of-concept, but AI is here now.”

To watch on-demand videos from the conference, visit https://connect.advantech.com/videos/ondemand/wpc2023.

Advantech

advantech.com

You may also like:

Filed Under: IoT • IIoT • Internet of things • Industry 4.0, NEWS • PROFILES • EDITORIALS, AI • machine learning, DIGITAL TRANSFORMATION (DX)