Miniature connectors for wearables continue to shrink, and they are increasing in performance, carrying higher bandwidth signals and more power. Wearables add functionality, resulting in more components and interconnects in the same size package. Applications range from smartwatches and health monitoring devices to augmented reality/virtual reality (AR/VR) devices, as well as medical and military systems.

This FAQ begins with a review of some advances in connectors for consumer and industrial wearables, looks at the requirements for medical and military wearables, and closes by briefly looking at medical wearables in military environments.

In addition to physical size and weight measurements, circular connectors are sometimes compared based on density factors. The density factor is equal to the receptacle diameter divided by the number of contacts available in that receptacle size. It can be useful for comparing connectors with the same size contacts. High-density connectors can be especially useful in data acquisition or other applications with a large number of channels. In some cases, such as power handling, contacts need to be a minimum size, limiting the possible density of the connector. Industrial or military devices used in harsh environments may need larger contacts to guarantee the reliability, again limiting the possible density.

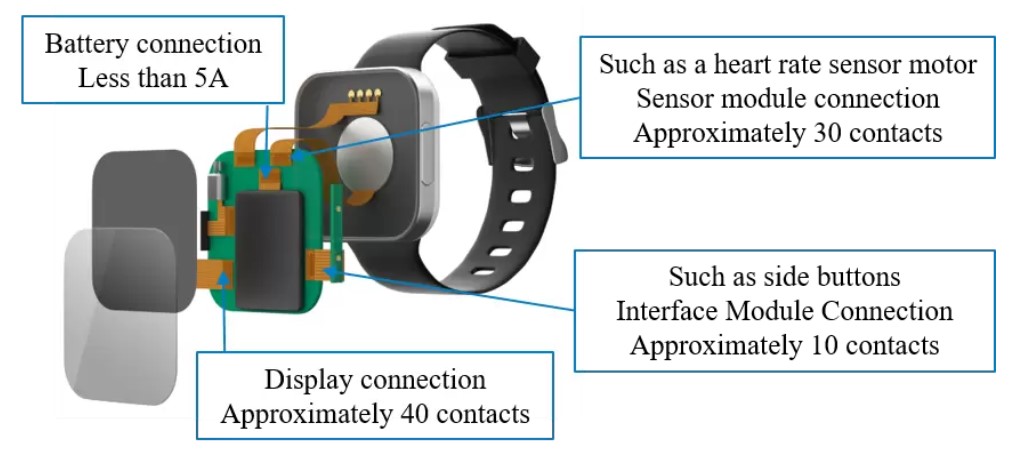

For example, high-density circular connectors are available in size 06 (10 mm diameter) that include up to 12 0.5 mm power and signal contacts for a density factor of 0.83. In another instance, a size 08 (12 mm) circular connector with 24 contacts is available with a density of 0.5. While the density is not that high, these connectors are up to 75% lighter than some comparable devices. Depending on the application, weight can be equally important as density. Size, weight, and power (SWaP) constrained applications such as wearables can have varying tradeoffs between density and weight. For example, applications like smartwatches need the smallest possible solution. Small format board-to-board connectors are available with contact pitches between 0.35 and 0.3 mm. These connectors have up to 40 contacts, which is optimal for smartwatches, health monitoring sensors, and similar wearables (Figure 1).

These compact connectors can handle signal rates over 10 Gbps and have an armored structure for robust performance and ease of integration into wearable devices. They can include a mix of power and signal pins, with the power pins rated for up to 5A each, enabling a connector with four power pins to handle up to 10 A of current for faster and cooler charging.

Medical wearables

The adoption of wearables in medical applications has been slower due to the extensive testing and regulatory requirements for those devices. Connectors used in medical wearables are judged by a different set of standards compared with devices for use in consumer and industrial settings. Some of those differences include:

- The medical device market faces greater regulatory challenges, and connectors must be designed to meet various needs for sterilization, ingress protection (IP) ratings, and heightened EMI/EMC requirements.

- Medical equipment makers are risk averse and adopt components such as connectors only after they have been proven in other application areas.

- Medical wearables do not rely on wireless connectivity as much as wearables used in other areas.

- Miniaturization is not as important for medical wearables.

While it’s not as important, miniaturizing medical wearables is still desirable. It’s more important in applications such as hearing aids or smart rings and less so in vests, armbands, and shoes (Figure 2). For example, board-to-board connectors for medical wearables are available with 4 to 60 positions, a 0.35 mm pitch, a 0.6 mm stack height, and current ratings up to 5A. Another family of 0.6 mm high board-to-board connectors is available with up to five signal pins and two power pins in a 1.7 mm width.

Flex printed circuit (FPC) to board connectors are also available with a pitch of 0.35 mm and a stack height of 0.6 mm. These FPC to board connectors are 1.9 mm wide and accommodate a variety of power (up to 5A) and signal pin configurations. The armored design prevents damage when mating, and these connectors have a self-alignment range of ±0.3 mm in the width direction and ±0.22 mm in the pitch direction.

Circular connectors are available that have been designed to be sewn into clothing for medical monitoring devices. They feature 360-degree mating freedom of movement and are IP68 rated, simplifying cleaning (Figure 3). The low profile design is rated for up to 10,000 mating cycles. The plastic version is IP67 rated, rated for up to 5,000 mating cycles, and is 70% lighter than the metal version.

Warrior wearables

Wearables are being used to increase the situational awareness of and improve coordination between warriors. Connectors used in these warrior wearables must meet the requirements of the U.S Nett Warrior program and the EU/NATO Generic Open Soldier System Reference Architecture (GOSSRA) program. Warrior wearables include displays and cameras, software programmable radios, geo-location and navigation, weapon monitoring, and other functions (Figure 3).

MIL-DTL-38999 circular crimp connectors are both a well-established standard and a good example of how miniature connectors are evolving to meet the needs of wearable applications. These connectors are continually being updated to meet emerging SWaP demands. The use of recently-developed composite materials enables D38999 connectors to support higher data speeds and frequencies in lighter-weight solutions. In one example, micro-miniature connectors meet the vibration and shielding requirements of D38999 but are 52% smaller and 72% lighter than standard D38999 connectors.

Miniature circular connectors designed according to the Nett Warrior specification and qualified to GOSSRA are available for critical communication, navigation, and USB data transmission in soldier wearables. Locking connectors are also available for Nett Warrior applications. In these connectors, the receptacle provides an audible and tactile indication when mated and includes an integrated locking mechanism to prevent accidental unmating. The locking mechanism also significantly reduces the force required to mate and unmate these connectors, and they can be mated and unmated with a gloved hand.

For densely packaged applications with critical SWaP demands, designers can use MIL-DTL-32139 rated nano miniature connectors in sizes from 2-28 positions with 0.64 mm (0.025 inch) contact spacing. These represent the smallest Mil-Qual circular connectors available. They are available in plastic housings or metal designs with threaded, twist-lock, and breakaway designs. The breakaway versions can withstand high levels of shock and vibration. These connectors have an extra retention spring that breaks away (releases the connection) at a predetermined force. Some models are rated up to IP68 for use in harsh environments. These are the smallest Mil-Quality circular connectors available today. With the ability to withstand high shock and vibrations while maintaining electrical integrity, the breakaway feature is ideal for the most demanding applications where size and ruggedness are valued. These connectors can include a variety of power and signal pins as required by the application.

Military + medical wearables

Being a warrior is a physically demanding and stressful activity. Military organizations are increasingly using a variety of wirelessly connected wearables, overlaying the Nett Warrior devices, to monitor and assess the physical wellbeing of warriors. These military-medical wearables monitor factors such as heart rate, body temperature, acceleration and distance traveled on foot to estimate energy expenditure and monitor physical condition (Figure 4). While wearable monitoring devices developed primarily for medical applications are expected to deliver high precision and accuracy, those factors are less important in military-medical monitoring. In military-medical monitoring wearables, the devices must be comfortable and not degrade the primary mission of the warrior. Connectors used in military-medical wearables must be small, lightweight, and unobtrusive. These devices are not meant to monitor small changes in physical conditions. Still, they are expected to provide alerts to heightened energy expenditures, excessively high heart rates or body temperatures, or other conditions that could negatively impact the primary mission.

Summary

Connectors for wearables are shrinking in size and growing in performance and variety. Wearables are used across various applications from consumer and industrial devices to medical, military, and military + medical. They are also used in environments with different SWaP requirements. In addition to meeting SWaP specifications, connectors are often subject to stringent signal integrity demands and harsh operating conditions such as the need to sterilize devices with medical connectors or the exposure of military connectors to high levels of vibration and shock.

References

Considerations for Connector Design in Mobile and Patient-Worn Medical Devices, Fischer Connectors

Generic Open Soldier System Reference Architecture, GOSSRA

No Soldiers Left Behind: An IoT-Based Low-Power Military Mobile Health System Design, IEEE

The Wearing Comfort and Acceptability of Ambulatory Physical Activity Monitoring Devices in Soldiers, IISE Transactions on Occupational Ergonomics and Human Factors

Trends and Connector Solutions in Wearable Equipment, Japan Aviation Electronics Industry

Filed Under: Connector Tips