DIN rail-mounted industrial power supplies feed dc power to industrial components for industrial control, assembly, testing, and monitoring tasks — as well as other automation equipment that uses dc power. These power supplies are usually found in electrical cabinets and control panels connected to elaborate power and communication networks involving myriad components. Outside control cabinets, power supplies can also be found on machinery providing power to HMIs, motor drives, actuators, sensors, and more.

Control-cabinet image via Dreamstime

Components that connect to industrial power supplies fall into two categories. The first category comprises distribution or intermediary power components that don’t use power themselves … but rather serve to connect the power supply to the industrial components needing power while performing other crucial functions. The second category includes electronic and electromechanical components that consume significant power to function. Industrial components in the latter category can directly connect to the power supply — or indirectly connect through an intermediary or a distribution component in the first category. After all, a significant number of power-consuming industrial components are intelligent systems containing processors and microchips demand finely shaped and controlled electrical power input.

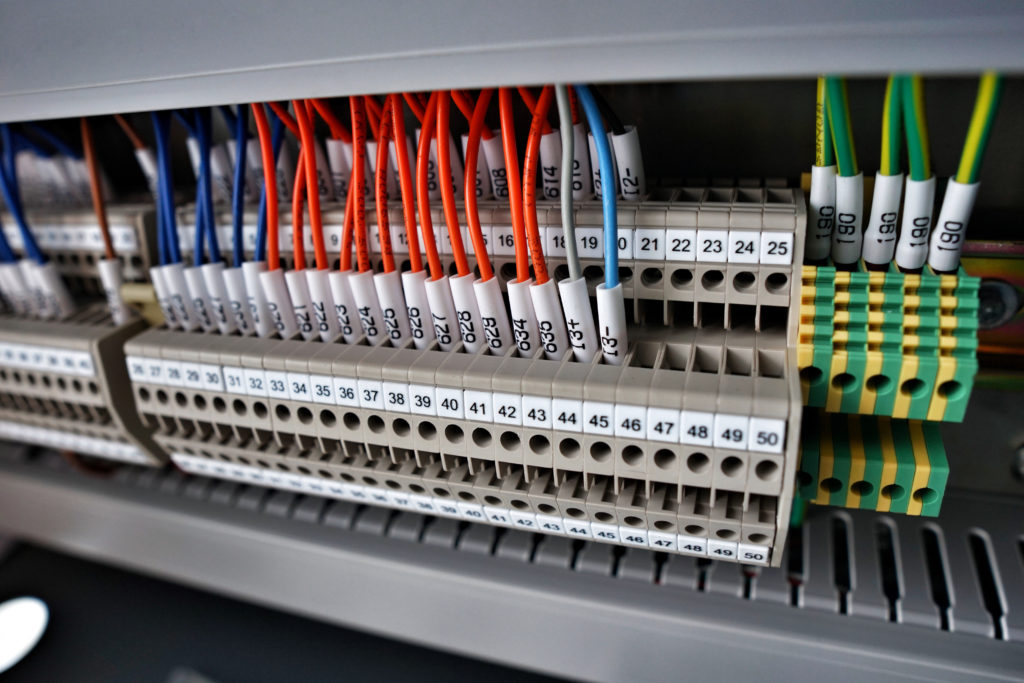

Terminal-block power-distribution image via Shutterstock

In fact, there are also a wide array of industry-specific power supplies and accessories — especially for automotive, process, aerospace, medical, food and beverage, and discrete manufacturing industries. It would be impossible to list all the specialized equipment in these industries employing power supplies. That said, following is a short list of exceptionally common industrial components that are quite frequently ganged with DIN rail-mounted industrial power supplies.

Terminal blocks and power distribution

Power distribution and terminal blocks fall under the first category mentioned above — intermediary power components that don’t use power themselves. These blocks are used to distribute power from a single power supply to numerous industrial components.

Mounted on this DIN rail are terminal blocks and (in the blue housings) relays based on electromechanical action.

Intermediary power components come in different sizes and have varying numbers of output terminals. In addition, power distribution and terminal blocks usually come with fuses connected to each terminal. The fuses may be rated differently … for terminals with different ratings. These components usually connect directly to the power supply from the power supply’s output terminals to their input terminal. They may also connect via an uninterruptible power supply or UPS.

Uninterruptible power supplies

UPSs are electrical industrial components that ensure that power is continually supplied to the connected load by a battery when normal input power is unavailable. They’re usually used for short periods until the main power is restored. A UPS may have an inbuilt battery or may be a standalone unit with a separate battery. In both configurations, the UPS’s input terminal connects directly to the power supply’s output terminals. UPS systems with separate batteries feature additional input terminals for the battery. This means that the battery never connects directly to the load. In addition, UPSs may have multiple outputs that connect to different loads. These industrial components act as both first and second-category devices (as described above) because after all, the supply power to other devices — and need power to execute their primary function.

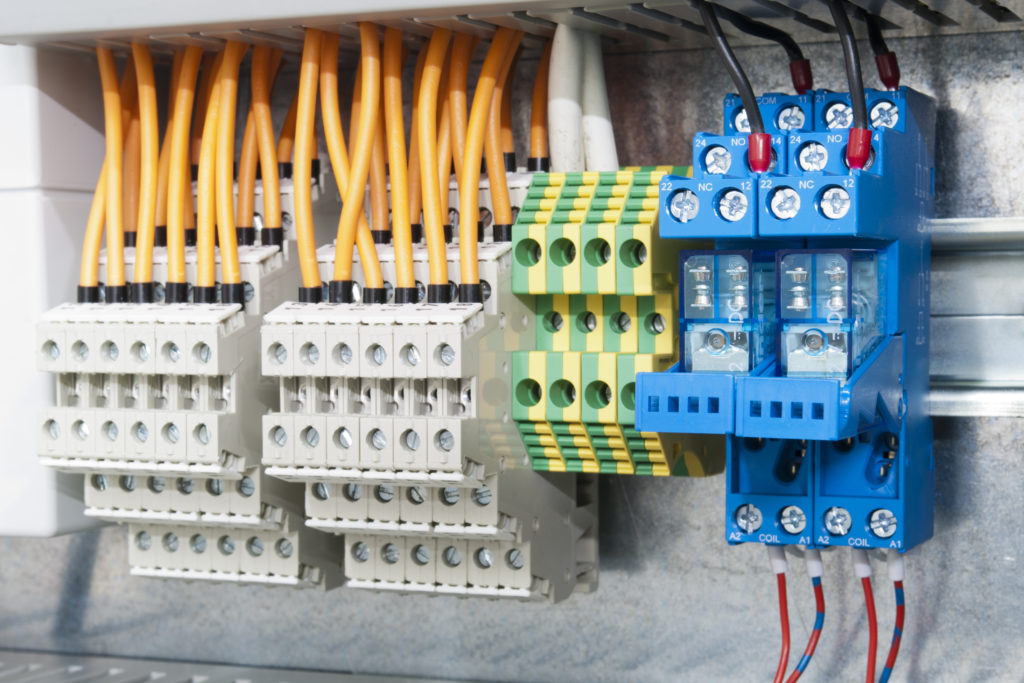

Industrial circuit breakers

Circuit breakers protect connected hardware from power surges and over currents. They are designed to trip (shut off the flow of current) whenever through current surpasses a specific level — in turn protecting connected industrial components. The way in which a circuit breaker connects to its power supply depends on:

• The type of circuit breaker — single or dual pole

• The type of power — whether single, dual, or three-phase

• The number of components connected to the circuit breaker

• The number of circuit breakers being used.

When several circuit breakers connect several components to a single power supply, a jumper bar can connect the circuit breakers to form a bank. Another common configuration is a dual-pole circuit breaker connecting a power supply to several components. Here the output terminals of the power supply connect to the input terminals of the circuit breaker, while the circuit breaker’s output terminals connect to any number of industrial components. One caveat is that all the devices connected to the same circuit breaker must have the same rating. Circuit breakers belong to the first category of devices mentioned above, as they don’t consume lots of power to execute their primary function.

PLCs connect to power supplies.

Power supplies and PLCs for automation

Programmable logic controllers or PLCs are dedicated industrial computers that carry out monitoring, control, and automation in industrial settings. They often install in control panels … and from there connect to the industrial components over which they exact various commands. These commanded components include sensors and limit switches, actuators, alarms, Ethernet switches, and numerous other industrial components. So PLCs inputs and outputs (whether integrated or via a separate module) connect to its programmable CPU. The inputs PLCs accept include feedback and status updates; output signals are low-power control signals. PLCs don’t supply power to the devices to which they are connected. Instead, PLCs feature positive and negative power-input terminals that either:

• Directly connect to a power supply’s output terminals or

• Indirectly connect to power supplies through a circuit breaker, power-distribution component, UPS, or other power component.

Wiring components to DIN rail-mounted power supplies

Most DIN rail-mounted industrial power supplies come with spring-clamp or screw output terminals that simplify the process of physically wiring power supplies to other devices. Connections are via cables of gage, strand count, and shielding and sheath type that are defined by the component suppliers.

Spring-clamp terminals on power supplies simply requires that the electrician or installer raise a small lever, insert stripped connecting wire into the corresponding wire receptacle, and then close the lever. Screw terminals offer more options but require that the electrician use a screwdriver to secure the wires in place. To wire a connection into a power supply with this receptacle type, the electrician loosens the receptacle screw until there’s enough allowance to allow wire or wire terminal insertion — whether that’s simply just a stripped wire end or a wire that terminates with a ring or prong-shaped end connector. Then after inserting the wire, the electrician tightens the screw down until the wire is held firmly in place.

Some specification and installation tips: Specify power supplies of sufficient size — to satisfy the power ratings (in Watts) of all components it will serve. Also: When connecting industrial components to a DIN rail-mounted industrial power supply, confirm their ratings match — to prevent damage to the power supply and the devices … and ensure reliable operation. Connecting a 5-A circuit breaker to a 10-A power supply will constantly trip breakers in the circuit. If the installation involves dc electrical systems, specify how the system should be grounded … by connecting either the negative or positive terminal of the power supply to ground. ⚙️ Contribution by Etiido Uko • Mechanical engineer

You may also like:

Filed Under: Power supplies