Gas springs, also called gas dampers, tension springs, gas-pressure springs depending on the setup and context, are compressed-air or oil cylinders that install in motion designs to damp forces and return kinematic linkages and more complicated assemblies to default positions. Gas springs work through a piston on the end of a rod that protrudes from a steel cylinder body; usually compressed gas (often nitrogen) within the cylinder exerts force on this piston to reassume and maintain set positions. Nitrogen is common here because it’s inert and nonflammable. In such designs, oil or grease between the piston and other contacting parts minimize friction.

In fact, the small amount of oil in these gas springs serves another function — to further damp and gently decelerate gas springs during full extension or compression. Some setups even include a fine hole in the piston for damping that’s still slower than with other designs; such slow-damper springs are common on safety gates and doors.

In contrast, extended-reach gas springs usually leverage telescoping mechanisms pairing multiple cylinders on one rod; then the smaller cylinder extends from within the larger cylinder. Consider one particularly long-stroke application: Passive heave compensators — systems on ships or offshore oil-rig systems that reduce the effect of waves on engineered structures — use gas springs with strokes to many meters long.

Consider one example application of gas springs: As Wuhan, China became the first metropolis to confront COVID-19, crisis managers relied on mobile X-ray machines to quickly supply intensive-care physicians with imaging of patients’ lungs. Medical-imaging machine builder Beijing Wandong Medical Technology Co. supplied these machines.

The mobile X-ray machine has beam arm that’s adjustable to patient anatomy. The arm in turn uses a gas spring to hold its position without dropping on technologists or patients.

When COVID-19 struck, Beijing Wandong suddenly needed a large quantity of springs to complete a rush order of the X-ray machines … so they turned to ACE Controls.

The mobile X-ray machine is 66.1 lb including its 22-lb beam arm. So in addition to the total weight, ACE Controls engineers had to account for the starting point (0°) and opening angle (130°) when choosing the specific gas spring.

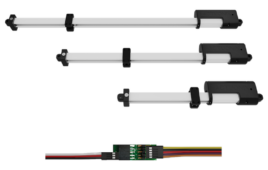

Ultimately the engineering team chose GZ-28-450 pull-type gas springs — part of the component maker’s industrial gas-spring family. GZ-28-450 gas springs have a 1.10-in. OD, maximum force to 2,700 lb, at a stroke length of 17.72 in. — making them suitable for the mobile X-ray unit’s requirements.

The gas springs reliably hold the beam arm in position and provide assistance when imaging technologists raise and lower the arm … in contrast with push-type gas springs. More specifically, the gas pressure in the cylinder draws the piston rod in and supports the manual force needed for controlled motion when moving the arm. No matter the stroke length, the GZ-28-450’s traction force is adjustable thanks to a built-in relief valve.

Ultimately, ACE Controls industrial gas springs boost the safety and user-friendliness of Wandong mobile X-ray units.

For more information, visit this deep link on acecontrolnews.com.

Filed Under: Linear Motion Tips