Renishaw offers a comprehensive range of non-contact encoders for position and motion control. These vary from open or enclosed optical, magnetic and laser encoders. Discover how our different types of encoder products can meet your industrial automation needs. Renishaw’s high-accuracy and high-quality encoders offer superior reliability, easy installation and are suitable for even the harshest environments. The FORTiS encoder series is a next-generation enclosed…

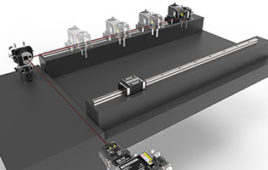

Renishaw next-generation FORTiS™ enclosed linear encoders offer enhanced metrology and reliability for machine tools

FORTiS™ is the new enclosed encoder that enables machine tool builders to improve machine tool performance and increase uptime while enhancing the efficiency of assembly, maintenance, and servicing. The innovative FORTiS enclosed linear absolute encoder series is designed for use in harsh environments such as machine tools. It can also be used in functional safety applications up…

Renishaw launches new line of industrial automation products

Renishaw unveils a new product line specifically designed for the industrial automation market. The new RCS product line builds on its existing expertise and technologies for industrial metrology applications and aims to transform the process of commissioning and servicing industrial automation technologies. Developed to solve some fundamental challenges within the global industrial automation industry, the…

Enhanced parallelism measurement accuracy with the XK10 alignment laser system

Global engineering technologies company Renishaw has released a new version of software for its XK10 alignment laser system which enables users to perform point-to-point parallelism measurements. This new functionality will also enable users to make precise adjustments to machine parallelism to a level that has previously been impossible using traditional measurement techniques. The XK10 alignment…

Renishaw and CCAT drive cutting-edge manufacturing and supply chain technologies

To assist manufacturers on their Industry 4.0 journey, global engineering technologies company, Renishaw, has partnered with the Connecticut Center for Advanced Technology (CCAT), USA. This applied technology demonstration and training center validates, demonstrates and assists with the adoption of leading-edge industrial technologies into the global manufacturing supply chain. The two organizations will assist businesses in…

The supportive role of metal additive manufacturing

The Covid-19 pandemic brought considerable attention to the 3D printing/additive manufacturing industry. Much of it focused on systems that work with polymer and resin materials. But what about metal additive manufacturing? How has the pandemic affected the metal side of additive manufacturing? Kevin Brigden, additive manufacturing applications engineer at Renishaw, addressed this and other developments […]

Renishaw puts it all together in its additive manufacturing operations

Renishaw Inc. has been in the additive manufacturing field for some time now. At a recent tour of the company’s new Chicago facility, I had a chance to see how they incorporate additive with their other manufacturing offerings and capabilities. They’ve developed a concept they call the productive Process Pyramid to describe and organize these. […]

Working with Cobalt-Chrome in additive manufacturing applications

Cobalt-Chromium-Molybdenum alloy, which is simply referred to as Cobalt-Chrome, is used in the dental sector. It is a derivative of the ISO 5832 alloy, or ASTM F75, that has its historical origins as a Stellite alloy, and which was originally developed as a casting alloy for orthopedic implant use. The dental alloy, however, differs from […]