At the upcoming IMTS 2024 in Chicago, September 9–14, Siemens will present its extensive machine tool CNC portfolio and digitization software technology, highlighted by the digital native SINUMERIK ONE control platform for machining applications. Also, using a sports theme of “Speed, Agility and Endurance,” aimed at the machine shop on its path to digitization, Siemens will introduce MACHINUM to the North American market. MACHINUM brings together machine tool controls, digitization software, and machine shop services from Siemens to help manufacturers optimize their production processes, provide agility for quick adaptation to changing customer requirements and calculated uptime needs, plus enable digitally proven endurance to maximize the productivity of the entire machine shop or production department.

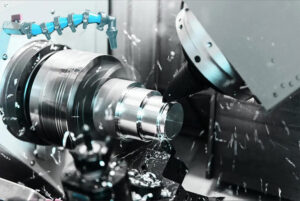

All CNC machining operations can be monitored and adjusted in real-time, through the various and customizable software platforms within the Siemens portfolio.

Detailing the elements of MACHINUM:

Speed

Siemens adaptive feed rate control reduces cycle times while maintaining a stable machining process. This results in Instantaneous and continuous analysis of the current cutting conditions on a machine tool in real-time optimizing the feed rate.

Agility

Through strategic digitization and software that seamlessly integrates the machine tool CNC systems and a shop’s internal communications, MACHINUM can significantly boost the agility of a machine shop or production department to accommodate changes in design, quantity output, and even machining characteristics, based on customer input and overall production and workflow landscape characteristics.

Endurance

Continuing the sports theme, over the long “run”, MACHINUM enables a heightened maintenance capability with leading “edge” machine monitoring that anticipates potential issues before they escalate, resulting in reduced cost and substantially less downtime on machines, due to unplanned maintenance. This feature is useful for linked and sequential production lines.

Siemens will have the eRod (an autonomous electric vehicle) on display, demonstrating the complete production of the aluminum wheel rims and gear housing.

MACHINUM also offers substantial benefits to machine builders, as Siemens integrated digital twin technology allows more streamlined off-machine programming and machining simulation in an office environment. This approach facilitates faster prep time, more accurate design specs on the final machine, faster component acquisition near the build time, and a reduction in costly downtime, due to last-minute design changes, as those are anticipated, simulated, and resolved, all in a virtual world. MACHINUM also represents the integration of existing Siemens digitization software such as Create MyVirtual Machine, Run MyVirtual Machine, Adaptive Control and Monitoring (ACM), Analyze MyWorkpiece, and Manage MyMachines.

Under the theme “Empowering the Digital Machine Shop”, Siemens will display its digital threads, from the blueprint to the finished part, digital twin to simulation, part production, as well as the total integration of these processes into the digital factory for job shops and production departments, all brought to life by Siemens hardware automation and digitalization software.

eRod continues its path

Building off the successful rollout of its eRod “electric buggy” at IMTS 2022, Siemens will further demonstrate the end-to-end production of the aluminum wheel rim and gear housing for this electric vehicle on display in the booth. The wheel rim is made by traditional 5-axis and multi-technology machining (mill-turn, turn-mill), and the gear housing is manufactured through additive/subtractive machining processes. At every stage of each part’s development, including machining, displays will take visitors through the digital manufacturing process. From the popular Siemens NX CAM software, which enables the use of 3D models, data, and processes to seamlessly connect planning and shopfloor operations, to the powerful SINUMERIK ONE, the digital-native CNC that permits a digital twin of the machine tool and its full operation in production, Siemens has streamlined machine shop operations as well as leading automotive, aerospace, off-highway, medical part and myriad consumer durable production facilities worldwide.

Additional highlights of the Siemens booth will include:

Aimed at developing a complete ecosystem for the machine tool builder and end-user, the Siemens Xcelerator portfolio joins the breadth of engineering and manufacturing to provide the optimum solution for customers of any size in any industry.

Digital Twin technology, where all machine design and operational kinematics are simulated before the machine is built, will shorten the machine tool builder’s time-to-market. The design, building, commissioning, and during startup and training phases of machine implementation will bring substantial savings to both the builder and end-user.

Siemens drives forward digital transformation in the machine tool industry with its

SINUMERIK ONE CNC platform.

With SINUMERIK ONE, Siemens is accelerating the digital transformation of the machine tool industry. The new CNC control platform works with software to create the machine controller and the associated digital twin from a single engineering system contributing to the total hardware and software integration. Thanks to its seamless interaction between the virtual and real worlds, including high-performance PLC, drive, and motor hardware, SINUMERIK ONE is setting new standards in productivity, performance, and digitalization. It is the future-proof machine controller in the increasingly digital world of manufacturing.

With Create MyVirtual Machine and Run MyVirtual Machine, SINUMERIK ONE comes with software to create the universal concept of the digital twin, powerful hardware, and integrated IT security, making it a forward-looking CNC.

Using Mcenter, the open and modular platform for efficient shopfloors, end-users can seamlessly link all their machine tools and networks with the company’s IT landscape.

Finally, a fun highlight at this year’s show, Siemens will hold a golf putting contest and raffle two putters twice daily during IMTS 2024. Siemens CNC hardware automation and digitization software will machine the putter heads, featuring custom engraving.

For more information about Siemens at IMTS 2024, please visit: www.usa.siemens.com

You may also like:

Filed Under: ENGINEERING SOFTWARE