Software, sustainability, and scaling are top-of-mind for additive manufacturing professionals. Design World shares findings from this year’s AMUG Conference and a glimpse of what’s to come.

Once again, the Additive Manufacturing Users Group (AMUG) Conference lived up to its reputation as a haven for 3D printing professionals to gather, exchange knowledge, and have a good time. The 2024 AMUG Conference took place at the Hilton Chicago on March 10-14 and offered dozens of presentations and panels, nonstop networking opportunities, competitions, awards, recognition, and much more.

The New Member Welcome reception marked the beginning of the conference and introduced first-timers to the event. The AMUGexpo followed, and the family reunion began. Hugs and handshakes abounded at every booth as attendees made their rounds. Exhibitors showcased prototypes and end-use parts to demonstrate the outcome of new materials and processes. Entrants of the inaugural AMUGderby placed their original 3D-printed cars in the lineup, and Technical Competition enthusiasts tried to get a sneak peek at this year’s novel ideas. (Catch up on more event highlights here: AMUG brings its annual conference “Back to the User”)

Throughout the week, AMUG leaders and keynote speakers started each day with insights and announcements. Afternoon breakout sessions focused on aerospace, transportation, defense, healthcare, materials, scanning, metrology, software, AM technologies, education, and training.

During the first morning session, AMUG committee member Todd Grimm shared industry trends from event sponsors and AMUG board members. Automation, sustainability, and workforce development were common themes, aside from advancing hardware and exploring new materials. Such topics echoed across the expo floor, at breakout sessions, and during casual networking conversations. Many exhibitors and attendees also emphasized software for increasing collaboration, productivity, and throughput to scale production, reduce costs, and support sustainability initiatives.

Design World sat down with various exhibitors and experts to learn what’s new and what industries can expect from additive manufacturing this year.

Address challenges head-on and prioritize business value

During an exclusive interview at the AMUG Conference, Brad Kreger, CEO of Velo3D, got candid about last year’s challenges and how strategic decisions rerouted the company.

“Looking back, 2023 was a challenging year for everyone in the industry. For us, a lot of that came in two flavors: reliability challenges and our sales process or commercial execution,” said Kreger.

Velo3D developed the Sapphire XC in a very short time and put systems out into the field quickly. Customers wanted to see their utilization rates on existing systems increase before scaling their fleets. So, Velo3D scaled up its field service organization by adding more staff and redirecting some of its R&D to targeted reliability initiatives.

The company found that customers were looking beyond the technology and needed to understand the business value of 3D printing.

“Don’t get me wrong, they’re interested in the technology, but at the end of the day, they’re buying a solution for a particular business need,” said Kreger.

Since then, the company rerouted its sales strategy and reduced operating expenses by 40%. This year, it’s focusing on enhanced training programs for staff and customers and developing customer success plans.

“We want to become a sustainable company. That’s something our customers want as well. They want to know that when they buy platforms for today, in five years and 10 years out, we’re going to continue supporting them and providing for their needs,” said Kreger.

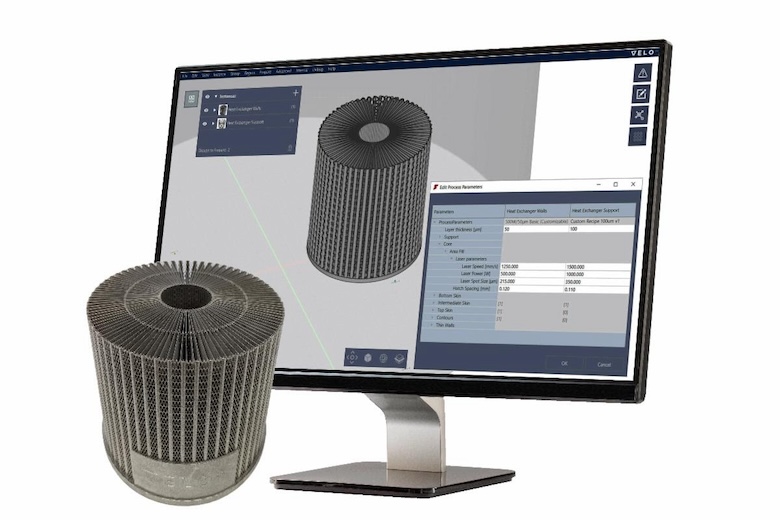

Before the AMUG Conference, Velo3D released Developer to help engineers optimize 3D printing processes and accelerate product development. Ursa Major used Developer to qualify a part once and reproduce the part multiple times at multiple locations without requalifying. The company also optimized its process and reduced print time by nearly 50%. Velo3D continues to support aerospace customers and intends to arm defense organizations with its enhanced print preparation software to help scale production and improve AM repeatability.

Connect discussions with designs

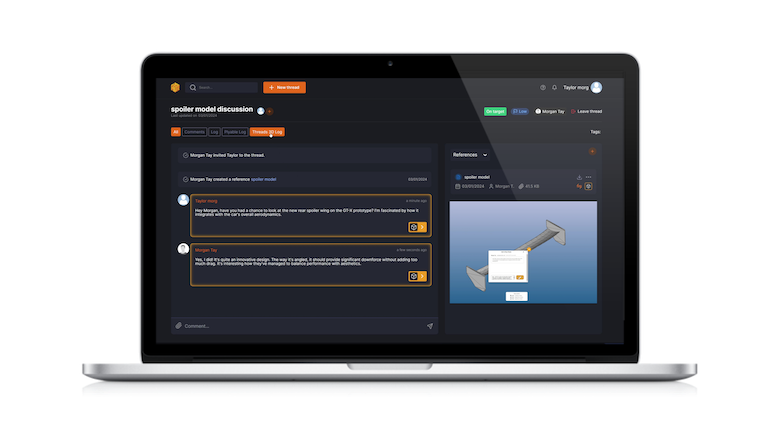

At the AMUGexpo, Authentise showcased new features for Threads, its collaboration tool that allows users to share, discuss, and manage engineering projects. It integrates human conversations and decision-making into the design process, which is especially useful for R&D and government organizations that require transparency and tracking.

“The biggest challenge exists in the space between an idea and a design,” said Andre Wegner, CEO of Authentise. “The only way we’re keeping track of conversations right now is through email, whiteboards, and Webex boards. The trouble in the additive world is when we want to reverse engineer something, the only information we have available is in the part or the designs, if we’re lucky. All the decisions that were made up to designing that part are lost. The moment that design exists, they’re lost. So, we wanted to give people a tool to collaborate effectively during the design phase.”

The tool integrates 3D models so that engineers can load a model, annotate a design, and have a conversation about it. Each conversation can have its own thread, and when decisions are made, engineers can tag it accordingly. This helps teams track projects during conversations and provides a historical record so that parts can be reverse-engineered or improved upon down the road.

Authentise also integrated its 3DGPT capability based on OpenAI’s ChatGPT. Organizations can use this to quickly search for information and assist with a project’s risk management process. For instance, traditional project risk management is a top-down process. With Threads, project managers can ask 3DGPT, “How many risks do we have in this project?” Based on the conversations, the AI can gather information and identify risks throughout the project.

Engineers and managers no longer need to mine email inboxes or play investigator searching multiple platforms to understand why decisions were made and how to replicate, repurpose, or learn from history. Authentise’s forward-thinking tool considers what people need now and in the future.

Make ceramics manufacturing simple

While medical, dental, aerospace, and R&D applications abound for ceramic 3D printing, there is a growing demand to scale for mass production and industrial uses.

“Ceramics are often a component in a device that performs a key function, such as a high-temperature electrical insulator, or for extreme environments where you need corrosion and wear resistance,” said Shawn Allan, VP at Lithoz America.

Lithoz’s CeraFab systems remain a leader in industrial-scale ceramics manufacturing with its easy-to-learn digital light processing (DLP) technology. Organizations use them to create green hydrogen production parts, microstructure ceramics, advanced high-temperature ceramics, multi-material electrical components, and dental solutions.

“It’s a DLP polymer process, and we’re printing with photopolymers. We clean the parts just like any other photopolymer process, and then we put the part through a final firing process. The complexity of the process is similar to polymer printing,” said Allan. “The post-processing firing isn’t terribly complicated. You use an oven or a furnace, you can run a range of programs depending on the material, and then you have a final part. Workforce-development-wise, the process is very teachable. In maybe one or two days of training, you can get somebody up and running to operate the system.”

Lithoz reported a 30% increase in printers sold last year and nearly doubled its material production from 2022, signifying an increase in worldwide adoption of ceramic printing. The company aims to boost ceramic 3D printing capabilities this year by increasing service bureaus, expanding its solution, and driving its “Ceramic AM Factory” vision toward serial mass production.

Reduce production costs with new materials

There are various ways to refine 3D printing processes to increase efficiency and reduce costs, such as optimizing designs and using automation. With its new PA 12 S material, HP helps engineers simultaneously reduce costs, improve sustainability, and create parts with enhanced surface finishes.

“When you do a production build on any powder printer, the powder stays inside the printer for a long time and degrades a little bit depending on its stability. So, for the next run, you need to put new, fresh powder in. It’s called the refresh rate. The lower the refresh rate, the less powder you need to add, and you don’t need to dispose of used powder, which is a big cost and sustainability issue. With the PS 12 S, there is no refresh, so you decrease the cost of production,” said Francois Minec, global head of polymers for HP’s personalization and 3D printing business.

In addition to reducing waste and build costs, the new material produces a surface finish that decreases post-processing needs.

“When you’re new to 3D printing, a good rule of thumb, though not always the case, is the cost per part is 30% materials, 30% printing, and 30% post-processing,” said Minec. “With this new product, we lower the post-processing cost.”

HP also aims to lead sustainability efforts in 3D printing by reducing the carbon footprint of its own product offerings.

“We’re reinforcing the message on two of the materials we have — the original PA 12 enabled by Evonik and the PA 11 enabled by Arkema,” said Minec. “These are the two main powders used in 3D printing today, and we’ve reached an agreement with our suppliers that they only use renewable energy to make these materials. So, the total carbon footprint decreases.”

Help 3D printing mature into adulthood

GoEngineer prides itself on enabling engineers throughout the entire ecosystem. The team helps with software, simulation, 3D scanning, 3D printing, and more. In addition to more than 60 offices across the U.S. and Canada, the company recently acquired Rapid PSI, a service bureau in Wichita, Kansas, that caters to aerospace.

During the 2024 AMUG Conference, the company described how 3D printing is growing from adolescence into adulthood and reiterated that no one is alone in their growth journey.

“We had a presentation called ‘From Mistakes to Mastery’ because it’s important to share learnings so engineers know they’re not the only ones who have made those mistakes, and it helps educate everybody along the way,” said Heather Natal, marketing product manager, manufacturing solutions at GoEngineer. “That’s really where our heart is — to educate.”

With blogs, YouTube channels, webinars, professional training, and 3D printing services, engineers have immense training and support from industry experts.

“When I entered the world of 3D printing, it was really in its teenage years. We knew the capabilities, but everyone was still figuring things out,” said Natal. “I see additive currently at a place of maturity. So, we’re looking at how to make this a profitable industry and partner with traditional manufacturing to encompass all of manufacturing. This is just another tool for manufacturing; it’s nothing to compete against.”

Despite its growing demand, Natal mentioned that the business case issue and materials can stall adoption. Therefore, as the number of materials and applications increases, we should see 3D printing explode in the market.

Scale 3D printing through software

About a week before the AMUG Conference, Stratasys released two new software packages: GrabCAD Streamline Pro and a new version of GrabCAD Print Pro for PolyJet. The company aims to help scale volume production by managing 3D printing fleets.

“What works with one printer doesn’t necessarily work when you get to 10, 12, 15 printers. And usually, you solve that with software and workflows,” said Victor Gerdes, VP of global software product strategy at Stratasys. “Print Pro is meant to help scale additive with automation, features to make parts with first-time success rates more often, and to help with greater throughput.”

Gerdes had examples of batteries and electronics parts where an engineer used PolyJet to “print air,” meaning it paused printing and placed objects into the prints. With the PolyJet series, engineers can also print on top of objects, such as fabrics, or directly on the tray, leading to better surface finish quality, and the J55 system can print twice as fast.

“If you think about Print Pro as the desktop app for print prep, Streamline is a workgroup app to connect people, parts, and printers to scale 3D printing,” said Gerdes. “We’re in beta testing now, and one of our customers said that with the analytics, they found that one of their printers had more uptime than the other. They didn’t know that was going on, and they were immediately able to investigate it.”

Adding more printers can introduce more risks, and managers need detailed analytics to assess each printer’s performance. With Streamline Pro, Stratasys addresses productivity, utilization, cost, and cybersecurity concerns for 3D printing fleets at any scale.

Get ready for more AMUG Conferences

AMUG members will return to the Hilton Chicago from March 30 through April 3, 2025. Registration will open later this year.

If you’re a return attendee, don’t get too attached to the Windy City! The following year, AMUG is moving to the Grand Sierra Resort in Reno, Nevada, March 15-19, 2026.

Visit amug.com for updates and announcements.

Filed Under: Make Parts Fast