By Chris Noble, Business Development F&B/IIoT Consultant

Emerson Automation Solutions

Today’s packaging machines are becoming better equipped with sophisticated automation systems that often include some type of pneumatics technology for actuation, filling, positioning, palletizing, depalletizing, etc. However, the digitalization and IoT benefits that can be realized from modern pneumatic systems are often overlooked.

The packaging industry has counted on pneumatics as a simple but reliable machine technology to package items from shampoo bottles and cereal boxes to egg cartons and cheese containers. In fact, most products on store shelves have interacted with pneumatics at some point, often in material handling. Even labeling applications can involve pneumatics.

Pneumatic systems are ideal because they tend to be a very forgiving machine element and a low-cost way to add motion to equipment. Pneumatic components are relatively simple to diagnose and fix — quite different than many other complex components found on a modern packaging line.

Another advantage is that pneumatics can easily adapt to certain changes in the operating environment, such as a slight variation in temperature or humidity or the introduction of a new packaging material. Pneumatic actuators are more tolerant when it comes to grabbing new products or package sizes, even when components and materials aren’t perfectly aligned on the machine. Contrast that with a complex servo system that can’t adapt as easily, causing issues that trigger downtime and expensive troubleshooting.

Improving machinery with smart pneumatics

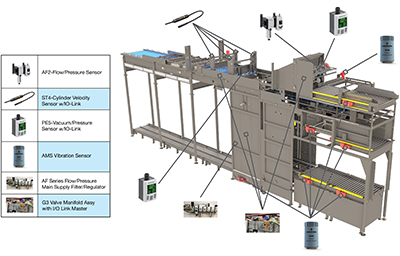

Pneumatics used throughout a packaging machine, such as a bulk depalletizer, can tie in with an overall automation system to provide comprehensive, actionable performance data to improve overall equipment effectiveness. (Machine image courtesy of Busse/SJI Corp.)

Pneumatics have long been considered a steadfast and cost-effective technology, especially when compared to all-electric solutions. Now, however, pneumatic systems are getting a fresh look from the OEM community as technology suppliers add intelligence to what were previously considered dumb devices.

In the past, it didn’t make sense financially to monitor data from a low-cost pneumatic actuator; you simply replaced it when it broke and dealt with the downtime. However, in reality, a $100 actuator could be a pinch point to the entire machine. Today, as sensing technology has advanced, it is now easier to monitor these actuators and get actionable data without being cost prohibitive.

The challenge for technology suppliers, OEMs and end-users is to work together to create systems that deliver useful intelligence. For example, agreeing on key performance indicators (KPIs) upfront can help ensure consistent machine performance that aligns with expectations. But end-users might not communicate the critical KPIs they need to manage. One solution is for OEMs to stay involved with the end-user after the equipment installation. This creates an opportunity for them to collect valuable feedback that can help solve customers’ pain points.

Pneumatics can tie in with an overall automation system to provide comprehensive, actionable performance data that can improve overall equipment effectiveness (OEE). Here are five key considerations for adding IoT-enabled pneumatics solutions that can make a difference.

1. Integrate pneumatics into the automation system

The advent of IO-Link, an internationally standardized input/output technology for machine communication at the sensor/actuator, allows for a new level of intelligence in data coming from sensors on the machine. IO-Link is independent of upper-level fieldbus systems and is available for almost all major fieldbus protocols. Machine sensor upgrades can increase functionality while keeping expansion costs to a minimum by using existing PLC controls.

Intelligent pneumatic devices, like the Emerson Aventics AF2 airflow sensor, can provide real-time insights on air flow, while also capturing pressure and temperature data in the feed line. (Image courtesy of Emerson.)

As a result, it’s becoming easier than ever to integrate smart pneumatics into existing automation platforms without changing the PLC, even with legacy systems. For example, as machines become increasingly high-tech, machine builders and end-users are trying to get more from their investment by running multiple levels of package sizes and weights on the same line. Sensors are now smart enough to adapt and collect different data depending on what’s coming down the packaging line. For pneumatics, that can include an automatic valve adjustment for an actuator handling a larger container size. The sensor can recognize the change in the packaging on the line and adjust its data collection parameters accordingly.

The combination of new digital technology and reduced implementation costs is allowing machine makers to leapfrog from basic data collection to advanced information that drives flexibility and freedom to maximize new machine platforms from day one. Taking a holistic view of data collection also allows improvements across the entire pneumatic system, from the compressor room to the operating environment and from the machine to the operator.

2. Compressed air consumption and leak detection

In the past, end users had no clear or concise insight into analyzing air consumption. So, if a compressor reached 80% capacity, for example, many consumer packaged goods (CPG) companies would often purchase another compressor to address the issue (sometimes costing up to $100,000).

Smart pneumatics allows CPGs to evaluate their compressor’s ability to drive new and existing equipment. Sensors can collect flow, pressure and temperature data, enabling advanced diagnosis of the operating parameters. For example, the AVENTICS AF2 flow sensor provides real-time insights on flow, while also capturing pressure and temperature data in the feed line. An increase in air temperature, for example, could indicate a compressor problem. Information on the current or cumulative energy consumption can be passed straight to the relevant parent system without requiring the machine control.

With this information, end users can look at differences and decide what levels are acceptable within a specific range. For a new plant, smart pneumatics present an ideal opportunity to establish a usage baseline and then analyze leaks or other energy inefficiencies over time.

3. Device life cycle management

Often, companies will add counters in their programmable logic controller (PLC) to count cycles on their actuators. Traditionally, a valve might be rated for a half million or million cycles, and when that point is reached the valve is replaced, whether it’s faulty or not. But a counter cannot account for changes, such as constant stopping and starting, that can significantly affect a component’s life cycle. As a result, the component may fail unexpectedly and cause expensive, unplanned downtime.

Local dashboard for pneumatics applications: The system shows in advance when critical limits will be reached and provides users with key information for early intervention. Local data is recorded independently of the control and information is supplied via standard interfaces, whether in a local IT network or in the user’s cloud solution. (Image courtesy of Emerson.)

Pneumatic sensors allow for better “real-use” data than a calculation based on numbers from a spec sheet. Now users can access data based on actual stroke and movement as well as speed. Sensors measuring speed are a recent innovation that can detect if actuators are pushed past a specific percentage — much like knowing the state of a car’s brakes based on gently using the brake pedal or slamming on it.

4. Actuator velocities, mechanical cushioning wear and vibration monitoring

Measuring actuator velocity can also help ensure better OEE. With smart pneumatics, end-users can now measure the consistency of an actuator’s acceleration and deceleration rates. The machine operator can use velocity to see if the action measures the same across time or if there are aberrations that require attention. Likewise, smart pneumatic technology can help monitor internal cushion wear to determine how aggressively the actuator is running into the cushion. Looking into data from these areas can review potential problems, such as worn cushions or misaligned pneumatic cylinder rods. The end result is scheduling maintenance accordingly to minimize downtime on the machine and keep OEE levels as high as possible.

For many OEMs, vibration monitoring serves as a starting point for IoT-enabled technology. The next level of smart pneumatics incorporates vibration technology built into the actuators. This technology has been used for some time in other areas, such as racing or robotics, and is being leveraged to identify the characteristics of specific machine components.

5. Operator adaption parameter changes

Many users think increasing data generates new layers of complexity. However, when implemented properly, IoT-enabled components can simplify data into maximums and minimums to help operators adjust machine or sequence performance. For example, if a machine drops beyond 10% of its optimal range, the operator will see more than a basic notification that something is wrong. The alert can also provide the issue’s location — like an indicator showing specifically which door of a car is ajar — saving time when troubleshooting to identify the specific problem instead of working down a time-consuming checklist.

The Emerson RXi2-LP industrial PC brings all sensor data together for accessibility, historian, visualization and analysis for primary product packaging machines or complete packaging lines. Real-time monitoring and diagnostics capabilities enable better OEE for the packaging line. (Image courtesy of Emerson.)

Smart pneumatics can also make it easier to implement and track parameter changes to ensure consistency across production shifts. For example, a beverage manufacturer running three shifts might regularly run into situations where different operator adjustments are made from shift to shift. Now, at the start of each shift, an operator can easily reset the machine components to automatically align with established settings, saving time during shift changes.

A good fit for packaging machines

Smart pneumatics technology is being used to help companies with digital transformation. It offers more efficient preventive maintenance as well as energy savings. In addition, smart pneumatics are scalable, whether it’s a new machine or legacy equipment that needs a retrofit. Ultimately, success hinges on partnering with an experienced pneumatics technology provider that understands the specific algorithms and applications where pneumatics is used. They can provide smart pneumatic monitoring systems with those algorithms embedded upfront, providing ready-to-leverage data— so machine makers and end-users can improve OEE.

Filed Under: Pneumatic equipment + components, DIGITAL TRANSFORMATION (DX)