Reduced effort, high value for automating hydraulic systems

By: Theobald Herrmann Product Management / Hydraulic Valves, Bosch Rexroth AG

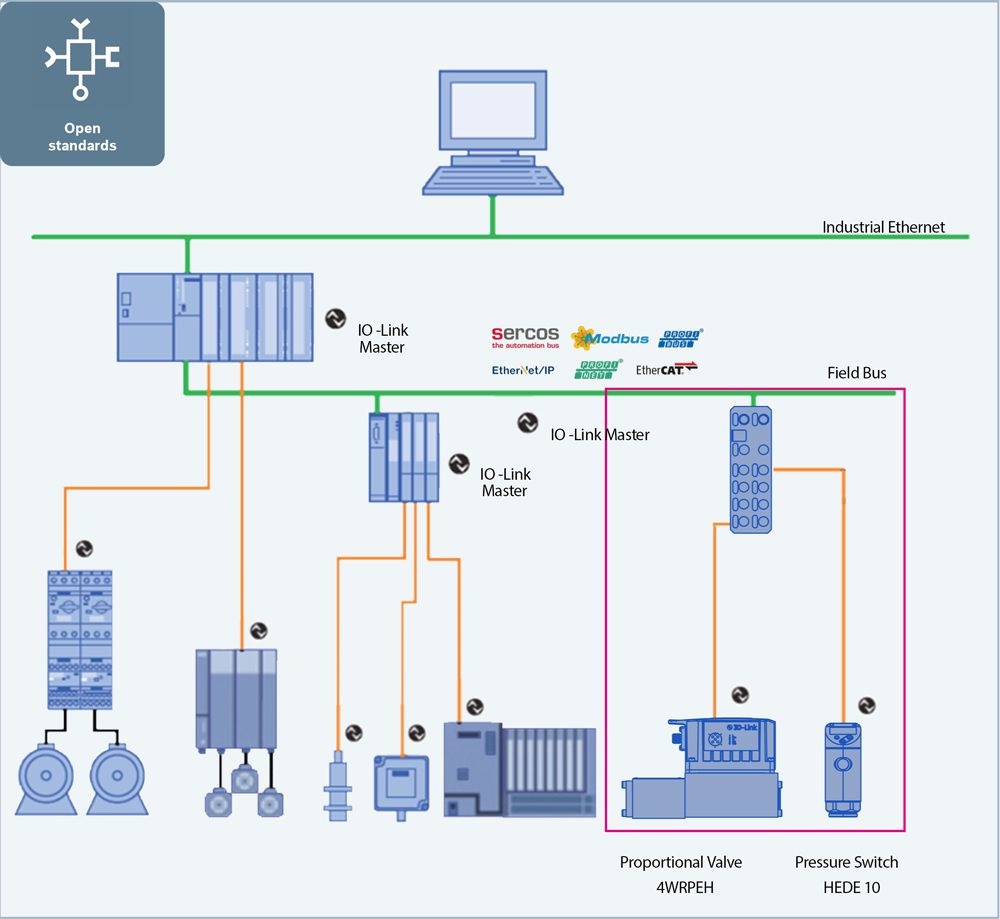

Figure 1. IO-Link integrates hydraulic valves and sensors with analog control in any type of automation structures and establishes bi-directional digital communication. [Click to enlarge.]

For actuators, sensors and other third-party equipment, either their manufacturers or system integrators are required to provide suitable interfaces in hardware and software for the respective fieldbus. This is very complex as device profiles and software have to be created in the respective PLC for every individual fieldbus and control system of each manufacturer.

Possibilities for hydraulic connection

Integration of hydraulics in modern automation systems can be realized in different ways. Numerous existing machine concepts apply on-board electronics for control of hydraulic valves. Exchange of digital information is restricted and only possible if the respective device is connected to a superior control system via individual wiring. But increasingly, this state-of-the-art in technology no longer meets the requirements of end users.

The alternative is using valves with integrated fieldbus connection. These, however, require extensive wiring — as well as integration into the control system and the respective fieldbus protocol by means of dedicated software. Both require considerable effort that is too high, particularly for price-sensitive applications. Thanks to IO-Link, machine manufacturer and system integrators are enabled to integrate for example proportional hydraulic series valves and sensors into digital communication structures with very little engineering effort. With its simple communication structure, IO-Link has low hardware requirements.

Additionally, the standardized M12 connection technology enables simple and cost-efficient connection of hydraulic valves in the field. This way, components with analog control are transformed into communicating and flexible actuators and sensors.

A look at IO-Link

The manufacturer-independent IO-Link — according to the IEC 61131-9 — standardizes connection technology for actuators, sensors and other equipment. It also provides a digital communication protocol for data exchange between control systems and devices, regardless of the fieldbus. Fieldbus technology is not replaced but extended. Parallel communication enables machine manufacturers’ use of IO-Link with all protocols and integration of IO-Link-compatible devices into various concepts without additional effort.

IO-Link is currently already supported by roughly 130 device manufacturers and other companies in the field of technology. IO-Link Masters are offered by about 40 manufacturers and the standard is supported by nine manufacturers of control systems. IO-Link devices are in the product range of almost 60 manufacturers of sensors, actuators and other peripherals.

Rexroth, for example, now also offers hydraulic proportional valves and pressure sensors with respective technology. Function and performance of these proportional valves are identical to series valves. However, they also offer all options for bi-directional communication via IO-Link. This way, the hydraulics can be integrated seamlessly into connected structures. What’s more, parameters can be changed and operating states changed by the control system during running operation.

IO-Link system set-up

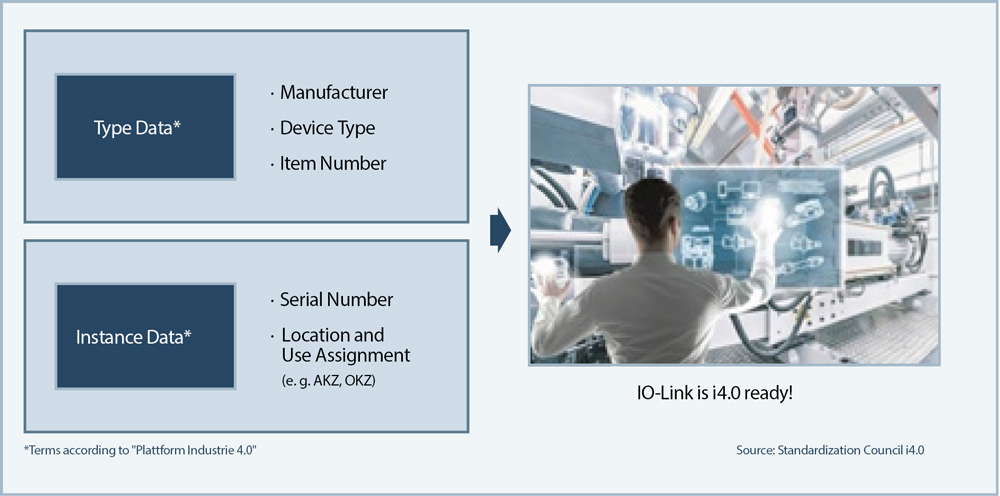

Figure 2. Ready for the future: IO-Link provides defined type and instance data and turns series valves into Industry 4.0 components. [Click to enlarge.]

IO-Link Masters are offered by approximately 50 manufacturers for connection of one IO device per port. The selection includes options for the IP20 control cabinet as well as decentralized modules with protection class IP65/67 for installation at machinery or systems. Particularly in large-scale systems, the amount of cabling is considerably reduced.

For decentralized IO-Link Masters, the user organization of IO-Link has defined M12 plug-in connectors with three or five conductors. The 5-pole version “Class B” port is used for devices with increased current consumption like hydraulic valves. The 3-pole version “Class A” port provides an energy supply of up to 200 mA, which is sufficient for most sensors. In contrast to analog controls, unshielded cables are sufficient for fault-free communication over a cable length of up to 20 meters. IO-Link standardizes connection technology for all actuators and sensors and eliminates numerous sources of errors during the installation of systems.

Otherwise complicated and expensive cable dimensioning with individual wiring and shielding is no longer required. In addition, the logistic effort is reduced thanks to application of uniform M12 cables for sensors and actuators.

Rapid commissioning per software

Every IO-Link device features an electronic device description, referred to as IO Device Description (IODD). It provides standardized important information:

- device data

- text description

- identification, process and diagnosis data

- communication properties

- device parameters with value range and default value.

- image of the device, and

- logo of the manufacturer

The IODD set-up is identical for all devices of all manufacturers. The IODD enables automatic recognition of the device by the IO-Link Master for immediate parameterization. Another automatic feature is that device descriptions are included in the system documentation. For project integration of the IO-Link Master in overall automation, commissioning personnel use the engineering tools of the respective PLC manufacturer. The IO-Link Master is selected from the device portfolio and added to overall automation. Depending on the control system manufacturer, all blocks for communication are available in a library for free.

Via IO-Link to Industry 4.0

IO-Link enables access to device data either directly from the control system or remotely via networks from any location. Particularly important for future-oriented concepts: Already today, IO-Link offers type and instance data of Industry 4.0 devices according to the definition of the German “Plattform Industrie 4.0” initiative.

In this way, hydraulic actuators meet all conditions for future requirements of Industry 4.0 applications. Additionally, this approach is well-suited for subsequent connection of existing machinery and systems with low effort. Users replace installed proportional valves and sensors by interchangeable options with IO-Link connection for direct communication with actuators and sensors.

Diagnosis functions for increased availability

The diagnosis functions of IO-Link devices enable new maintenance concepts and considerably reduce repair times. Now, possible call-up of device information in parallel to the process forms the basis for condition-oriented and predictive maintenance concepts. In this respect, proportional valves report whether they are functional as well as errors such as under- or over-voltage and electronic temperatures exceeding a set admissible value. In addition, the valve and sensor status are displayed for transparent error analysis. An integrated operating hour indicator enables calculation of the residual life cycle for maintenance and decision-making on further use of the valve.

In case of faults, IO-Link accelerates diagnosis, thanks to remote access for maintenance specialists to identify the type and location of any errors. Precise localization without personal presence at the system alone considerably reduces reaction times. If necessary, the maintenance technician opens the IODD file of the respective device in the control system. Now, components do not need to be disassembled to decipher hardly readable labels and manufacturers and types no longer need to be looked for in system documentations. Thanks to the electronic name plate, all this information can now be accessed with just one mouse click to initiate the respective order without delay.

IO-Link follows the plug-and-play principle. Replaced devices are recognized by the IO-Link Master according to their IODD file and the respective parameters are automatically transferred without any actions in the software. This way, even less experienced technicians are enabled to replace components without problems to considerably reduce system downtimes.

Concluding thoughts

The open IO-Link standard establishes continuous communication with sensors and actuators irrespective of the used fieldbus. Now, even hydraulic proportional valves can be intelligently, easily and cost-effectively, integrated in bi-directional digital communication. This simplifies commissioning in hardware and software and enables flexible adjustment of hydraulic valves for varying production processes.

Increased requirements for flexible machinery and systems are now in compliance. Extended diagnosis information enables condition-oriented and predictive maintenance concepts and standstill and maintenance times are reduced. This increases the availability of machinery. In addition, IO-Link enables future-proof integration of hydraulic valves into connected structures as Industry 4.0 components with all their related features.

Bosch Rexroth

www.boschrexroth.com

Figure 1. IO-Link integrates hydraulic valves and sensors with analog control in any type of automation structures and establishes bi-directional digital communication.

Figure 2. Ready for the future: IO-Link provides defined type and instance data and turns series valves into Industry 4.0 components.

Filed Under: FLUID POWER