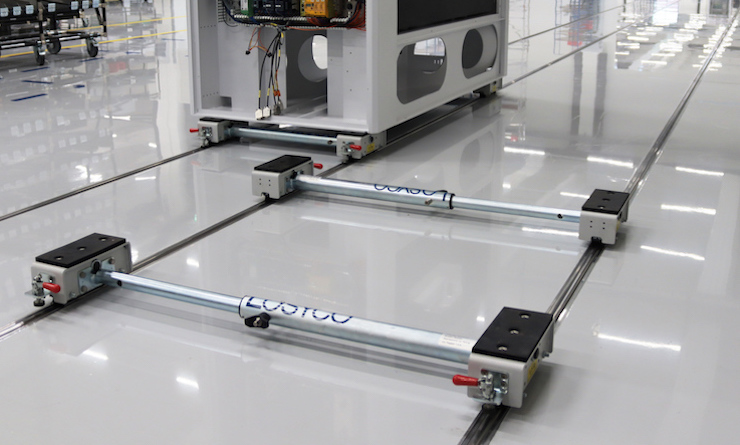

LOSYCO, a specialist in rail-based intra-logistics and feeding systems, has provided five floor-level LOXrail floor rail system tracks for a German machine manufacturer’s two assembly lines.

A newly developed transport solution allows the transport system to be adapted to three different track widths. A telescopic axis connects two customized carriers with a 1.5-ton payload, each featuring two double-roller wheelsets. This enables variable transport setups for machines with different dimensions. Loads are directly positioned on the carriers, which feature a rubberized contact surface.

For example, machines can be placed on a two-axis combination and manually pushed from one assembly station to the next. Larger machines can be transported using all three tracks and four carrier combinations alternately positioned on different tracks.

The carriers can be designed for payloads up to 5 tons for even more enhanced flexibility and scalability of the LOXrail system, which has already proven itself worldwide in various applications for optimized production logistics, material flow and machine feeding across all industries. The floor-level rail system ensures barrier-free access on the shop floor for staff, mobile racks and pallet jacks.

Filed Under: Linear Motion Tips