By Danielle Collins | Business Development Manager — Semiconductor • Bosch Rexroth

With computer chip shortages affecting virtually every industry, semiconductor manufacturers are working rapidly to build new fabs and expand existing production lines. This increase in manufacturing capacity creates major opportunities — and challenges — for automation technology suppliers.

Consider that the typical chip production cycle takes six to eight weeks for completion. Some chips can take longer, involving 1,500 to 2,000 steps and six months to process. By some estimates, only a quarter of the processing time for a semiconductor wafer is spent in chambers — the rest is spent transporting wafers in and out of chambers and between tools or waiting for tool time.

Wafer transport requires precise, vibration-free motion to avoid damage or costly scrap. Endpoint accuracy is equally critical. Before processing can begin, the wafer must be perfectly stable and properly aligned. Any additional time required for vibration to dissipate or for the system to reach its precise position significantly impacts throughput and cost.

Tool builders can address these challenges with new controller and servo drive platforms that offer more flexibility and precision in motion control. Refined motion control techniques, such as feed-forward algorithms, predict and compensate for position and velocity conditions at the end of a motion sequence to ensure precise positioning and minimal vibration and settling time.

With an open, app-based approach, a new generation of automation controls offers greater scalability and engineering freedom. For example, engineers who need a specific drive or controller capability can add the functionality as an app — just like adding an app on a tablet or smartphone — rather than reworking the entire automation program.

Plus, to minimize footprint and maximize performance, servo drives that combine compact, space-saving designs with performance characteristics that minimize vibration and settling time equip tool builders with control and size capabilities to address their most critical requirements.

But high-performance wafer handling systems require more than powerful controllers and drives. The linear systems that physically move the wafer stages need equivalent precision, rigidity, and positioning accuracy. Linear motion systems used in wafer transport assemblies must have high levels of mechanical stiffness to minimize deflection and ensure high accuracy in both travel and positioning.

Ball screw drives provide superior stability and control for semiconductor tool applications. They are ultra-efficient at converting rotary motion to linear motion, offering a unique combination of high rigidity, high precision, and fast travel speed while maintaining the necessary cleanliness.

Regarding linear guide systems, it’s essential to assess the smoothness of ball recirculation inside the bearing block as it moves along the linear guide. As the balls travel through the bearing block, even minute pulsations can adversely affect applications requiring high accuracy. Technologies that optimize recirculation at key transition points provide extremely smooth and consistent motion as the balls circulate.

Custom subassemblies offer complete wafer transport solutions

With the pressure to rapidly engineer and deliver wafer transport solutions, tool designers and builders are more frequently turning to experts in mechatronics and automation for complete, ready-to-install subassemblies.

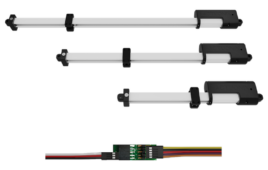

In one example, Bosch Rexroth developed a fully integrated wafer lift assembly combining compact servo drives, motors, a controller, and ball screws to fit within a tight space inside a wafer processing tool. The space-saving design reliably exceeded the customer’s target of five million cycles while providing a 30% cost reduction versus a version the tool builder was trying to design and develop in-house.

Effective subassembly development should utilize a holistic view of design rather than a serial design. Best practice is to begin by assessing the mechanics before forging ahead with the electrical and control design. Understanding how mechanical elements affect motors and controls will help avoid problems later.

For example, if a design is based around a specific motor without first considering the mechanics, larger mechanical components may be required to handle the motor’s torque or inertia. This could result in “over-specification” when a smaller motor and mechanical components could have been used instead if the mechanics had not been designed around a specific motor.

It’s also important to program the motion controller and drive parameters with the correct, safe torque and end-of-stroke limits to ensure that the linear system does not overshoot its position limits. Also, consider how the mechanical components affect other system parts, such as encoders. For example, if a ball screw-driven module can achieve one micron in position repeatability, the encoder must also have a resolution of one micron or better; otherwise, engineers cannot take full advantage of the ball screw precision.

Most critically, it is imperative to size the mechanical and electrical components together to achieve an acceptable inertia ratio for the application’s dynamics and precision. Choosing linear components or systems based on inaccurate or overestimated performance criteria can lead to a system that is more complex and expensive than necessary.

Although some subassembly suppliers procure components from multiple vendors, if these third-party suppliers don’t have experience in the unique requirements for semiconductor tools, problems may arise. For example, if the lubrication used in mechanical components is not cleanroom certified, the lubricant could release contaminants that can ruin wafers, costing tens of thousands of dollars.

There are multiple advantages to working with suppliers that engineer, manufacture, and integrate all subassembly elements into a complete automation solution that meets the application’s unique requirements. If a tool requires some modification due to new motion control requirements or the need to substitute a part due to supply chain issues, a custom subassembly manufacturer with complete control over its manufacturing and supply chain can test, document, and validate any modification to the design.

Options to improve handling and conveyance

Some semiconductor fabs can improve throughput and efficiency by using new multi-axis handling and linear motor conveyance systems.

Smart mechatronic handling systems now offer a “plug-and-produce” concept to simplify mechatronics development. Online selection tools let machine builders and system integrators quickly size and select key components — linear systems, drives, motors, cabling, and more — to create a complete handling solution delivered as a single product.

These systems also come with commissioning software for automated drive recognition and utilize drag-and-drop motion sequences pre-configured for various functions, along with digital twin capabilities for programming efficiency.

For fab operations with multiple vacuum chambers, linear motor transport tools with an external noncontact motion system provide a new solution for wafer handling. Coils mounted outside the chamber provide drive power for magnetic carriers inside the chamber, offering the precision, feedback, and control of linear motors without having cables pulled into the vacuum chamber. They also allow individual carriers to move independently for specialized processing needs.

Automation partners support tool builders’ objectives

Automation plays a critical role in semiconductor manufacturing, but with pressure to implement cutting-edge technologies while reducing development time, tool builders need to maintain focus on their core competencies, such as lithography, etch, or other critical processes. By partnering with an automation supplier who understands the unique requirements and challenges posed by semiconductor applications, equipment builders can reduce their design, prototype, and testing timelines while optimizing their tool’s performance and reliability.

Bosch Rexroth

boschrexroth-us.com/semiconductor-info

Filed Under: Linear Motion Tips