NORD’s industrial automation solutions include MAXXDRIVE industrial gear units, UNICASE parallel shaft gear units, UNICASE helical bevel gear units, IE3 – IE5+ high-efficiency electric motors, and NORDAC variable frequency drives. These solutions are engineered to work in unison for ultimate performance in demanding, heavy industrial environments.

Industrial gear units from Nord Drivesystems are used for heavy-duty applications such as bucket elevators, mixers, agitators, cranes, conveyor belt drives, bulk material handling, steel production, manufacturing, and more. These units provide high output torques, long service life with minimal maintenance, and offer extensive input, output, and mounting designs to ensure versatility over many applications. High performance and smooth operation are achieved with high-efficiency motors and dynamic variable frequency drives.

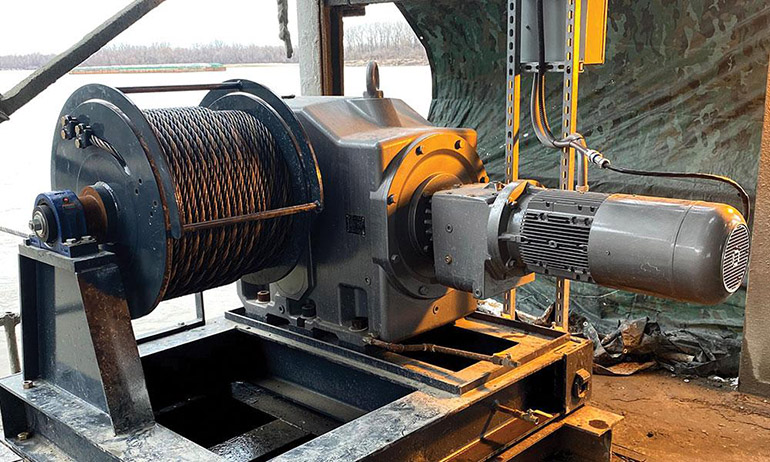

NORD complete drive solution used for a barge winch application.

Grain industry solutions

In the grain industry, drive systems must increase productivity, improve reliability, and reduce downtimes. Drive solutions in this sector often include functional safety and hazardous environment protection due to dust and fibers generated during processing. For high-capacity applications like bucket elevators used for vertical transport of bulk materials, NORD offers MAXXDRIVE XC parallel industrial gear units and MAXXDRIVE XC right-angle industrial gear units. These industrial gear units deliver immense output torques up to 2,495,900 lb.-in and feature a wide range of additional options ideal for bucket elevator applications. These include a backstop to prevent material flow back, an auxiliary drive with an overrunning clutch, a base frame for reinforced alignment between components and easy installation, taconite seals to stop shaft damage from the dusty atmosphere, and axial fans for high cooling power.

Crane/Hoist industry solutions

For cranes and hoists to pick up loads and set them down gently at precise locations, they require special drives with integrated brakes and variable frequency drive technology for soft starts and braking via defined adjustable ramps. MAXXDRIVE XD industrial gear units are engineered with hoist applications in mind and feature an extended housing center distance to accommodate a U-shaped drive design, allowing the cable drum and the motor to be arranged on the same side of the gear unit. The UNICASE housing is also FEA-optimized for overhung load, especially downward forces. It also offers additional options such as brake attachment through input flange or brake console and various output shaft designs. With intelligent NORD VFDs like the decentralized NORDAC FLEX and cabinet-mounted NORDAC PRO SK 500P, high positioning accuracy, efficient automation, and smooth operation are achieved. These variable frequency drives can also be synchronized for gear units to work in tandem to hoist and move loads for trolley or travel drive applications.

Wastewater industry solutions

The wastewater industry is known for its harsh operating environments, so drives in this setting must be built for durability and corrosion protection and have an optimized sealing system to keep debris out. NORD’s industrial offerings for this highly specialized industry include UNICASE parallel shaft gear units, UNICASE helical bevel gear units, MAXXDRIVE industrial gear units, and NORDAC FLEX variable frequency drives. UNICASE parallel shaft gear units are commonly used for surface and brush aerator applications because of their high radial and axial load capacity, advanced sealing system, heavy-duty (VL) bearing options, and flexible horizontal or vertical mounting options. These units also feature a spread-bearing design with a DRYWELL option for additional oil leak protective measures.

Food & beverage industry solutions

The food and beverage industry uses drive systems for heavy-duty applications requiring various torques, speeds, and protection measures. NORDAC FLEX and NORDAC PRO SK 500P variable frequency drives allow drives to be controlled individually, with speeds adjustable to prevent jams and material sticking, along the sides of mixing, agitating, or dough kneading machines. NORD’s industrial stack mixer design features twin UNICASE helical bevel gear motors with shafts turning in opposite directions optimally to mix ingredients in mixers and agitators. Additional options ideal for industrial applications in the food and beverage industry include extra-strong output shaft bearings for heavy loads, temperature sensors for overheating protection, smooth surface motors for easy wash-down ability, and food-grade lubricants are also available.

NORD complete drive solution used for a barge winch application.

Bulk material handling industry solutions

For many systems in the bulk material handling industry, the NORD complete drive solution includes either a MAXXDRIVE industrial gear unit or large UNICASE helical bevel gear unit, an IE3 asynchronous motor with hazardous protection, and a NORDAC FLEX or NORDAC PRO SK 500P variable frequency drive. Due to their compact design and load capacity, UNICASE helical bevel gear units are commonly used for conveyor applications. Whereas MAXXDRIVE industrial gear units are used for applications with greater torque requirements to handle the mass flow rate, efficiently, and reliably transport bulk goods. VFDs are also an important part of the solution due to their functional safety features, integrated brake rectifiers for motor brake control, and POSICON integrated positioning mode for precise control. The drives can additionally be controlled individually to intelligently meter, weigh, and adjust the bulk goods flow rate to reduce backups and breakdowns and be implemented with customer-specific process functions such as automatic blockage detection/elimination and automatic mass flow regulation.

With their widespread industry knowledge, application expertise, and global sales and technical support, NORD DRIVESYSTEMS is prepared to configure complete drive solutions for even the most specialized industrial automation systems.

NORD

www.nord.com

You may also like:

Filed Under: Gears • gearheads • speed reducers