Leuze electronics, a provider of sensor solutions based in Germany, has announced relocating and expanding its U.S. headquarters operation to Gwinnett County, Georgia. The company’s decision to bring its operations from Michigan to unincorporated Duluth, Gwinnett County, centered around Georgia’s best-in-class business environment and access to diverse talent. The relocation represents a significant investment of…

Technology report: Methods for risk assessment

The European Machinery Directive requires a risk analysis should be performed for every machine before being brought to market. The convergence of IT and OT and the rapid technological development has made it necessary to revise the Machinery Directive. The result is the new Machinery Regulation: It will replace the Machinery Directive as the legal…

Laser diffuse sensor integrates time-of-flight technology.

Small housing, big operating range: Thanks to TOF technology, the new ODT3CL1-2M compact diffuse sensor from Leuze achieves an operating range of up to two meters. The 2-in-1 sensor detects the presence of objects and at the same time transmits measurement values. With the new ODT3CL1-2M laser diffuse sensor, the Sensor People from Leuze are […]

New Leuze location in the USA

Duluth in the northeast of Atlanta, Georgia, will in the future be the new Leuze location in the USA. “After careful consideration, we have decided to move our office to a new, more modern, and more spacious US location,” says Ibrahim Zuva, VP Operations and Technology Americas. This decision is consistent with Leuze’s long-term strategic…

Leuze is turning 60 and continues its ambitious growth

In 1963, who would have thought that the fragile “Electronics” seedling, the new division of the Leuze Group, would become a technology and world market trailblazer in optical sensors? In 2023, Leuze is celebrating not only record growth, but also its 60th birthday. Leuze — a long-standing family business The creation of the electronics division…

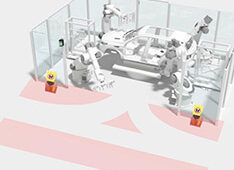

Leuze technology report: Dynamic interactions made safe

During automated material transfer between robot cells and automated guided vehicles, people must not stray into the danger zone unnoticed. An innovative solution by Leuze secures the transfer stations by means of dynamic protective field adjustment. This makes additional safety measures such as barriers and fences unnecessary. Risk-free full automation In smart factories, the flow…

Leuze tower lights provide clearly visible light signals

Tower lights are indispensable in machine and system construction as well as in intralogistics: They make states, faults, and ongoing processes clearly visible from a distance. The new Leuze tower lights of the TL 305 series can do all of this extremely reliably. They light up brightly, uniformly, and fully. This enables optimum signaling —…

Ultra precise thanks to ultrasonics

Compact ultrasonic sensors from Leuze: The new sensors of the HTU200 and DMU200 series master challenging applications in the packaging and automotive industries by themselves. New, compact ultrasonic sensors from Leuze: The sensors of the HTU200 and DMU200 series are particularly suitable for applications in the packaging and automotive industries. They reliably perform difficult detection […]

Leuze announces a change of management

By 2025, Leuze will have doubled its sales growth since 2020, and not for the first time. With a sales increase of 25%, Leuze took another big step toward achieving this ambitious goal in 2022. And the company is set to make further investments: in international structures as well as in its employees and new…

Stay flexible safely

By Matthias Bristle, Product Manager Safety Solutions Leuze electronic GmbH + Co. K,G Different material widths, varying material positions, or partially loaded pallets pose special challenges for transfer station access guarding. For this, Leuze relies on the concept of dynamic format adaptation. In this way, productivity and safety can be optimally harmonized. Variation becomes…

Leuze sets new standard for compact positioning system

The AMS 100i from Leuze is one of the smallest laser positioning systems available on the market. This makes it the perfect solution for tight installation spaces. Whether on the stacker crane, automated guided vehicle, or lifting system: In automated intralogistics, the sensors used for positioning applications must be able to operate on a small…

Leuze: Put into the right light

Many light types and a compact housing: The new KRT 3C contrast sensor from Leuze can be flexibly integrated into packaging processes thanks to its multicolor capability and small size. With the KRT 3C contrast sensor, Leuze is presenting the smallest contrast sensor it has ever made for the packaging industry. Plant operators benefit from…

New Leuze plant in Malaysia begins operation

After a construction time of just 16 months, Leuze has opened its new production site in Malacca (Malaysia). With immediate effect, Leuze sensors will be produced there for the international market. Leuze’s Asian customers are primarily supplied from Malaysia. Based on 2020, sales of the Leuze electronic group should double again by 2025. For the…

Safety light curtains are easy to integrate and install

Leuze is bringing to market the new ELC 100 safety light curtains, which can be used to reliably guard points of operation: The devices contribute to making machine designs cost effective and are easy to integrate and install. Manufacturers and operating companies of machines and systems can now use new Leuze safety technology for contactless…

36 sensor series from Leuze

The new 36 sensor series from Leuze detects objects even at large operating ranges. Manufacturers and operators of highly automated systems benefit from the cost-optimized design of these sensors. The accurate detection of objects requires reliable technology: Leuze has developed the new 36-sensor series exactly with this in mind: Thanks to their detection performance, these […]

New 36 sensor series from Leuze

The accurate detection of objects requires reliable technology: Leuze has developed the new 36 sensor series exactly with this in mind: Thanks to their perfect detection performance, these sensors are suitable for the demanding requirements in intralogistics, packaging systems, and the automotive industry. They detect objects with different optical properties – even at a great distance, with vibration, […]

Reliable detection of multipacks

The new dynamic reference diffuse sensor DRT25C.R from Leuze detects various film-wrapped bottles and cans fault-free. It uses the conveyor as a reference, and because the detection does not rely on objects, no adjustments are required when changing products. Leuze is expanding its range of dynamic reference diffuse sensors with the DRT 25C.R container sensor. […]

More safety in harsh environments

Rolf Brunner, Senior Safety Expert, Leuze electronic GmbH & Co. KG 3D safety systems are a good option for reliably monitoring danger zones. They present a safe alternative, even in harsh environments where, for example, sparks, dirt, and dust occur. They are therefore also a solution for applications where previous optical sensors were unable to…

Guided container and tray identification made easy

Leuze is introducing the latest addition to the BCL series with the new stationary bar code reader BCL 200i. It supports guided container and tray identification, especially suited to tight installation spaces on the conveyor line. As an expert in the field of identification, Leuze has been producing bar code readers since the 1990s. The…

Leuze presents the GSX, the world’s first combined fork sensor

With the new GSX combined fork sensor, Leuze is once again introducing a worldwide innovation. This product combines the advantages of light and ultrasonic sensors. The GSX sensor is exceptionally suitable for labeling machines used in the packaging industry. With the introduction of the GSX, the world’s first combined fork sensor, Leuze is continuing its […]

Leuze presents the GSX, the world’s first combined fork sensor

With the new GSX combined fork sensor, Leuze is once again introducing a worldwide innovation. This product combines the advantages of light and ultrasonic sensors. The GSX sensor is exceptionally suitable for labeling machines used in the packaging industry. With the introduction of the GSX, the world’s first combined fork sensor, Leuze is continuing its […]

DRT 25C dynamic reference diffuse sensor’s innovative detection method for challenging shapes and surfaces

The primary and secondary packaging of confectionery and baked goods can be challenging: The new DRT 25C dynamic reference diffuse sensor from Leuze solves precisely this problem in an innovative and reliable way: with a one-of-a-kind reference technology and three light spots. The DRT 25C reliably meets the high requirements of packaging machines for confectionery…

Announcing Leuze´s Newest Partner, Cornerstone Technical Group

Cornerstone Technical Group, provider of automation solutions, has partnered with Leuze to offer an extensive line of sensors and corresponding accessories for industrial automation in six different product areas. The German-based company is an expert in innovative and efficient sensor solutions for industrial automation. With 20 years of experience, Cornerstone Technical Group excels at guiding…

New TPE and PVC yellow sheathed cables for industrial applications

Leuze electronic has expanded its cable and connectivity solution offerings with the introduction of 75 new yellow sheathed TPE and PVC cables. These cables are perfect for heavy duty industrial and especially automotive related applications – welding robotic cells, ect. With inventory and technical expertise on site at its US headquarters, Leuze electronic presents tailored […]

Intelligent cable allows predictive maintenance on moving cables

Leuze electronic presents a concrete innovation towards powering Industry 4.0 applications with its new Smart Core cable. With the smart factory revolution on the horizon, the Smart Core cable enables an innovative predictive maintenance measure specifically for applications with moving cables (i.e handling robots, welding robots, moving cables). The cable contains an additional, special sacrificial […]