The PCI Industrial Computer Manufacturer’s Group (PICMG) is developing a series of specifications to enable plug-and-play interoperability of smart sensors and effectors. The effort includes the large installed base of legacy non-IoT (not IP-enabled) devices and newer IoT-enabled smart sensors. The PICMG program includes development of a family of three IoT specifications. PICMG IoT.1 is the second of those standards.

This FAQ presents an overview of PICMG IoT.1, looks at the previously released PICMG IoT.0 standard, and reviews the progress toward the third and final standard in the series, PICMG IoT.2.

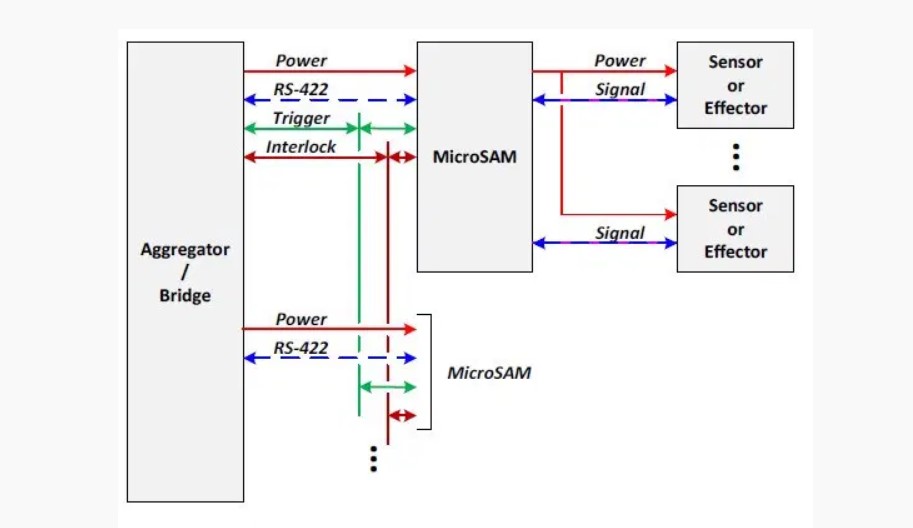

IoT.1 supports sensing and motion control needed in many emerging Industry 4.0 applications. It defines a firmware interface and low-level data model providing vendor-independent configuration of smart sensors and effectors, as well as plug-and-play interoperability with higher levels of the installation. Before IoT.1, PICMG addressed the lowest level of the hierarchy where the physical sensors and actuators of the factory equipment exist. Each of these devices may or may not be IoT-enabled, so PICMG developed IoT.0 (also called MicroSAM) to address the issue of hardware interoperability (Figure 1).

The IoT.1 specification is a joint effort between PICMG and the Distributed Management Task Force (DMTF) organization. To more thoroughly address the needs of Industry 4.0, IoT.1 leverages and extends DFTF’s Platform Level Data Model (PLDM) specification. PLDM is a low-level messaging system that supports topologies, eventing, and discovery, and runs over a variety of system-level buses such as I2C/SMBus and PCIe Vendor-Defined Message (VDM) over Management Component Transport Protocol (MCTP), Reduced Media Independent Interface (RMII) based transport (RBT) over Network Controller Sideband Interface (NC-SI), and others. Benefits of IoT.1 include:

- Enabling the production of smart sensors based on control circuits and software from PICMG compliant suppliers.

- Enabling the interoperability of smart sensors and smart sensor components from various makers.

- Enabling integrators of sensors and smart effectors to use devices and controllers from multiple suppliers.

- Speeding the adoption of smart senor technologies in Industry 4.0 through open specifications that ensure interoperability

Building on MicroSAM

The Micro Sensor Adapter Module (MicroSAM) is a compact computing module developed specifically to meet the needs of sensor-domain control in the Industrial Internet of Things (IIoT) and Industry 4.0. MicroSAM was the first IoT specification from PICMG. It was developed to solve the challenge of integrating non-IoT devices. MicroSAM is a 32 mm x 32 mm low-power microcontroller board that allows non-IIoT-enabled devices to interact with an IIoT gateway in a plug-and-play manner.

The introduction of MicroSAM filled a need not addressed by other PICMG specifications; a module designed for use with MCUs in the sensor domain. It’s optimized for processing performance and I/O connectivity for that purpose. In addition, MicroSAM can be used with other PICMG devices such as MicroTCA, COM Express, or CompactPCI Serial, which provide higher layers of control, while MicroSAM provides sensor-optimized connectivity.

MicroSAM co-exists with and extends the existing ecosystem by offering a standards-based solution designed specifically for embedded use in Industry 4.0 applications. The basic features offered by MicroSAM are:

- Industrial operating temperature range from -40 to +85 °C

- Industrial grade power filtering and signal conditioning for embedded installations

- RS422 communications

- Direct connectivity to analog voltage, analog current, and digital sensors

- Secure connectivity using latching connectors

- Pulse width modulation (PWM) output for motion control applications

- Synchronization using hardware interlock and trigger signals

- Compact (32 mm x 32 mm)

When combined with the PICMG sensor-domain data model and network architecture and data model, sensors connected to MicroSAM modules seamlessly integrate into the network with plug-and-play interoperability (Figure 2).

Coming soon: PICMG IoT.2

The PICMG IoT.2 network architecture specification is expected to be ratified later this year. It defines the integration of smart sensors and effectors, as well as their data, into larger Industry 4.0 systems of systems. IoT.2 is based on DMTF’s Redfish API and outlines an abstraction layer and transactional model so that sensor and effecter endpoints can be monitored and managed in the context of job models similar to those available from cloud service providers. When used together, IoT.1 and IoT.2 are intended to support the analytics required for higher productivity levels and throughput across a factory environment (Figure 3).

- 1 provides low-level visibility of physical device parameters that can directly impact the quality and efficiency of your production line

- 2 provides an IT-like interface for managing both machines and jobs at a high level of abstraction.

To support collaboration, the PICMG IoT.2 standard will enable existing IoT communications protocols and models to be converted to maintain compliance with the new specification. The strategic alliance between PICMG and DMFT enables IoT.2 to use RedFish APIs. RedFish is a RESTful (Representational State Transfer) interface for the remote management of a platform. REST is simple, well-established, and easily facilitates client and server interactions. RedFish Framework benefits include:

- Easy for machines to parse and generate, and for people to use

- Scalable for use in Industry 4.0 systems of systems

- Re-uses established principles in well-organized formats

- Secure, extensible, and interoperable

The RedFish interface definition includes JavaScript Object Notation (JSON) and the Open Data Protocol (ODATS). ODATS is an ISO/IEC-approved OASIS standard that defines a set of best practices for building and consuming RESTful APIs. The RedFish interface leverages common Internet and web services standards, and its hardware management concept is very similar to PICMG’s Hardware Platform Management (HPM). Building on the RedFish communication protocol, PICMG expects to add capabilities for motion control such as multi-cast capability and network time protocol (NTP) clocking. Additional security features will be included before the final release of the PICMG IoT.2 network architecture specification.

Summary

PICMG is developing a series of three specifications to enable plug-and-play interoperability of smart sensors and effectors. The specifications cover the large installed base of legacy non-IP-enabled devices and newer IoT-enabled smart sensors. The initial PICMG IoT.0 specification was developed to solve the challenge of integrating non-IoT devices. The recently released IoT.1 specification defines a firmware interface and low-level data model providing vendor-independent configuration of smart sensors and effectors and was designed to support sensing and profiled motion control needed in many emerging Industry 4.0 applications. The still-to-be-released PICMG IoT.2 will complete the effort and defines the integration of smart sensors and effectors, as well as their data, into larger Industry 4.0 systems of systems.

References

Industrial IoT Overview, PICMG

MicroSAM System-on-Module Standard Targets Microcontrollers, IIoT Sensors, CNX Software

PICMG Ratifies IoT.1 Firmware Specification for Smart IoT connected Sensors and Effecters, PICMG

Filed Under: Sensor Tips