Dorner and its partner company montratec are set to unveil its latest innovations in assembly technology in booth 1224 at Automate 2024, May 6-9, at McCormick Place in Chicago. With a focus on enhancing efficiency and reliability in production environments, both Dorner and montratec will present a lineup of demo conveyors designed to meet the diverse needs of various industries.

Dorner is a provider of design, applications, manufacturing, and integration of conveyor automation systems. German-based montratec is in the conveyance industry, serving customers of all sizes primarily in the automotive, EV, plastics, and medical device industries.

The newly released DualMove Pallet System will lead off Dorner’s collection. The DualMove features twin-strand timing belts that glide pallets precisely from one stop to the next. It also features three accessory modules: lift and transfer, lift and rotate, and lift and locate. DualMove’s reliability, flexibility, and easy integration make it a great fit for numerous assembly applications.

Among the featured conveyors is the ERT150, an industry-ready solution engineered to convey medical and cleanroom-based product assembly. Boasting a versatile, low back-pressure platform, the ERT150 offers seamless and adaptable performance for various appliance, electronics, automotive, and consumer goods assembly applications. Its simple and effective design, including non-contact zoning and slip roller accumulation capability, ensures safe and efficient operation while minimizing downtime. With ISO Class 4 verification for cleanroom applications, the ERT150 sets a new standard for precision and reliability.

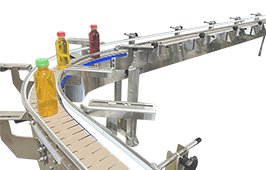

Also on display will be Dorner’s FlexMove Pallet System, a versatile conveyor engineered for product routing, control, and inspection in small- to medium-size assembly automation applications. The FlexMove line is sold as completed assemblies or as kits. It offers users layout flexibility and the ability to implement easy conveyor system design changes to adapt to their business’s evolving needs. Modules include merge and divert modules, lift, and locate stations, cushioned pallet stops, and a unique pin tracking system to guide pallets through 90° turns — all of which attach directly to the conveyor frame without modifications.

Columbus McKinnon’s newest acquisition, montratec, will feature their montrac mono-rail solution at Dorner’s booth. montratec’s intralogistics solutions for manufacturing, assembly, and production processes minimize cycle times and maximize customer operational throughput. Asynchronous movement enables products to be moved independently in multiple directions at varying speeds to balance production lines, increasing flexibility and productivity. montratec also brings a higher level of cleanroom certification that expands market access in the EV, life sciences, electronics, and semiconductor industries.

Lastly, Dorner will feature its renowned 2200 industrial series conveyor solution. The 2200 series loop showcases the uniquely low-profile industrial line of conveyors and their ability to seamlessly transfer products from one conveyor to the next.

To see how the entire collection of Dorner and montratec automation platforms can help your automation, e-commerce, material handling, food, and packaging applications, make plans to visit their booth 1224 at Automate 2024. For more information on Dorner’s conveyor platforms, visit www.dornerconveyors.com.

You may also like:

Filed Under: Conveyors