Rutgers computer scientists used artificial intelligence to control a robotic arm that provides a more efficient way to pack boxes, saving businesses time and money.

“We can achieve low-cost, automated solutions that are easily deployable. The key is to make minimal but effective hardware choices and focus on robust algorithms and software,” said the study’s senior author Kostas Bekris, an associate professor in the Department of Computer Science in the School of Arts and Sciences at Rutgers University-New Brunswick.

Bekris, Abdeslam Boularias and Jingjin Yu, both assistant professors of computer science, formed a team to deal with multiple aspects of the robot packing problem in an integrated way through hardware, 3D perception and robust motion.

The scientists’ peer-reviewed study (PDF) was published recently at the IEEE International Conference on Robotics and Automation, where it was a finalist for the Best Paper Award in Automation. The study coincides with the growing trend of deploying robots to perform logistics, retail and warehouse tasks. Advances in robotics are accelerating at an unprecedented pace due to machine learning algorithms that allow for continuous experiments.

The video above shows a Kuka LBR iiwa robotic arm tightly packing objects from a bin into a shipping order box (five times actual speed). The researchers used two Intel RealSense SR300 depth-sensing cameras.

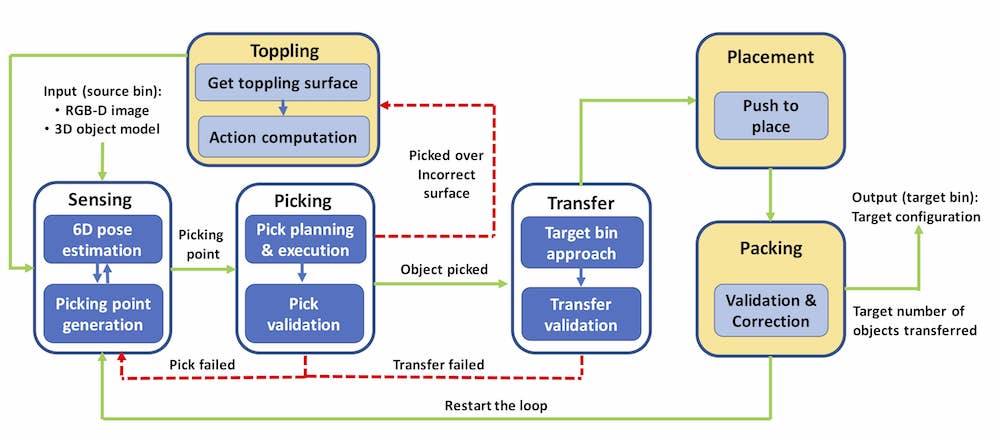

Pipeline in terms of control, data flow (green lines) and failure handling (red lines). The blocks identify the modules of the system. Click image to enlarge. | Credit: Rutgers University

Tightly packing products picked from an unorganized pile remains largely a manual task, even though it is critical to warehouse efficiency. Automating such tasks is important for companies’ competitiveness and allows people to focus on less menial and physically taxing work, according to the Rutgers scientific team.

The Rutgers study focused on placing objects from a bin into a small shipping box and tightly arranging them. This is a more difficult task for a robot compared with just picking up an object and dropping it into a box.

The researchers developed software and algorithms for their robotic arm. They used visual data and a simple suction cup, which doubles as a finger for pushing objects. The resulting system can topple objects to get a desirable surface for grabbing them. Furthermore, it uses sensor data to pull objects toward a targeted area and push objects together. During these operations, it uses real-time monitoring to detect and avoid potential failures.

Since the study focused on packing cube-shaped objects, a next step would be to explore packing objects of different shapes and sizes. Another step would be to explore automatic learning by the robotic system after it’s given a specific task.

Editor’s Note: This article was republished with permission from Rutgers University.

Filed Under: AI • machine learning, Warehouse automation, The Robot Report

Tell Us What You Think!