Automated mobile equipment, which transports items in warehouses and freight centers as well as assembly operations, continues to boost demand for power-transmission and motion control systems. In fact, the worldwide mobile-robot market will reach nearly $15 billion by 2026, according to researchandmarkets.com. Almost all run off electric-motor drivetrains that are relatively expensive upfront but with high controllability, very low cost of ownership due to use of economical electricity for power, and modest maintenance requirements. Utility task vehicles (UTVs) and all-terrain vehicles (ATVs) are a couple examples.

Of course, many autonomous ground vehicles (AGVs) and other professional service robots (including those for logistics, remote inspection, and off-highway markets) carry subsystems to execute very specific tasks previously done manually. These require sophisticated motion controls. Geometries abound and include a wide variety of grippers, linear actuators, and multi-axis platforms and kinematic subsystems for manipulating and transporting payloads.

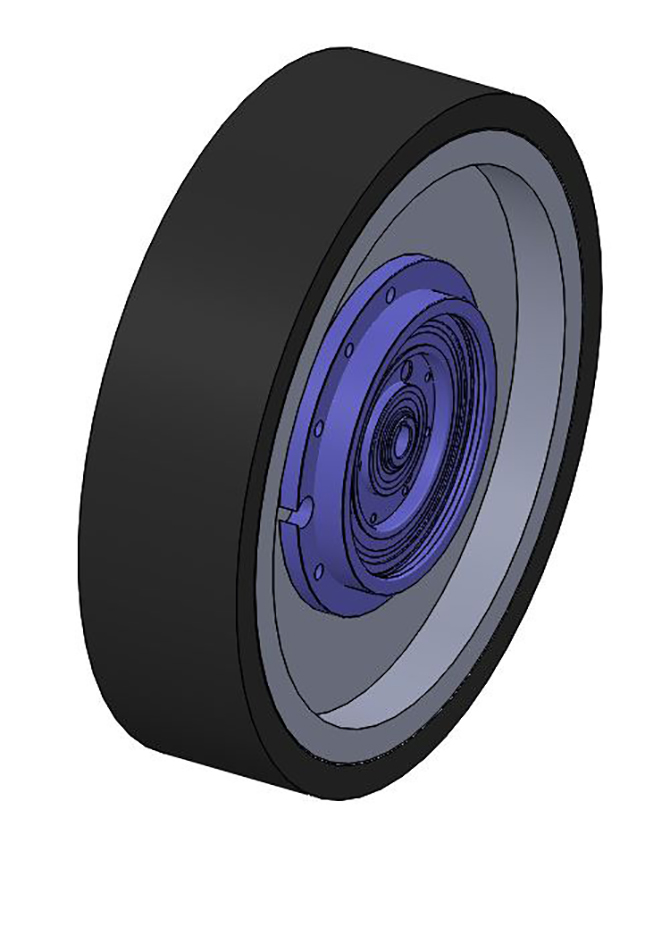

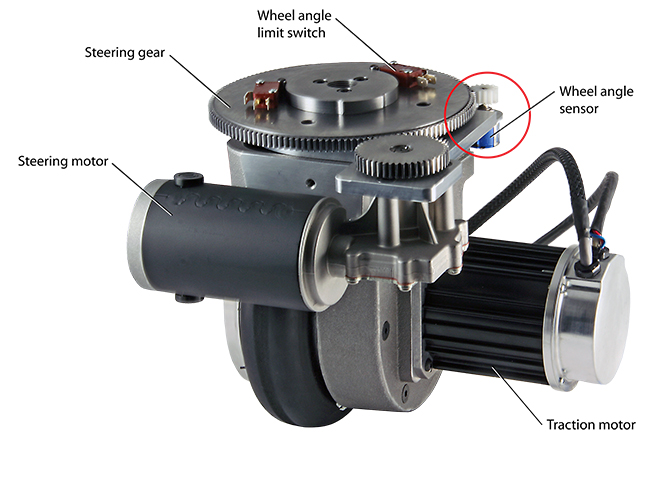

These are Allied Motion Technologies motors and integrated wheel assemblies for traction and steering applications in robots and automated vehicles.

Even for end-effecting tasks such as quickly picking items from storage racks and co-mingling them into shipment boxes, electric actuators are often more efficient than the pneumatics traditionally used for gripping. That’s because electric actuators draw power only when operating to let operators run (for example) electric forklifts and material-handling vehicles all day and only charge them overnight.

Visit therobotreport.com/category/robots-platforms/agv for more on this topic.

Where mobile designs run off onboard rechargeable battery power — and in traditional off-highway vehicles that aren’t autonomous but also include automated systems and actuators — such efficiency is crucial. Direct-drive motion technologies including linear motors for end effectors (and traction motors for wheeled drives) are leading options for designs having particularly demanding requirements.

Electric actuation allows tight control over position and imparts IIoT functionality. The latter is particularly useful on AGVs and other autonomous mobile designs. The traction drive shown here from Applied Motion Products includes onboard motion control and brushless servomotor, planetary gearbox, and flange to mount a drive wheel. I/O and communications network to vehicle computers and sensors without external drive (amplifier) electronics. The design’s high torque density (and low servomotors inertia) make powerful yet efficient drives for AGVs as well as autonomous mobile robots (AMRs), electric bicycles, and electric wheelchairs. Setup of motion controls is through Q Programmer software; programming includes commands for controlling motion and more.

Another motion profile that is typical of mobile-robot subsystems — especially for position-sensing assemblies such as light detection and ranging (LiDAR) and other tracking systems on autonomous vehicles — is that of precision rotary motion with high duty cycles.

Recall that LiDAR serves to map a mobile robot’s surrounding environment to avoid other vehicles and hazards.

Such motion-sensing systems are core to the functionality of autonomous mobile robots (AMRs) that move items in factories and warehouses from origins to destinations often set on the fly. Complementing the frameless-motor-actuated laser-based sensing systems in these AMRs are usually PC-based motion controls that command wheel-drive servomotors while concurrently networking to facility ERP connections for IIoT functionality.

Nanotec compact wheel drives are for AGVs. They include a PD4-E brushless dc motor with integrated controller; a magnetic single-turn absolute encoder with 1024 PPR and CAN interface; a GPLEP 70 7:1 planetary gearbox; and mounting flange. With versions for right-side and left-side operation, the drives include a gearbox with reinforced ball bearings on the output side to withstand high radial and axial loads. The 100-mm wheel O.D. is PEVODYN-Soft 78° Shore A. Other motor-gearbox options and fieldbus interfaces are available.

GAM Enterprises has engineered gearboxes to fit in AGV wheel hubs and satisfy challenging design requirements — include the need for the wheel hub to support the vehicle’s weight.

Trends in battery-powered and mobile motion designs

Allied Motion Technologies systems engineer Jeffrey Shearer confirmed some specifics about rising levels of automation in material handling. Much of this trend is the result of increasingly cost-effective material sourcing and production of robotic technologies first developed for aerospace and military applications. His company supplies subsystems for AGVs and other battery-powered equipment in this market.

“We see many new motion designs for robotic systems aimed at automating material handling. In warehouse and material-handling AGVs, there’s increased demand for autonomous material-handling carts … and these often use bldc motors paired with encoders and electronics to drive their traction wheels,” said Shearer.

Some designs also include Z-axis ballscrew actuators to raise and lower material-handling surfaces … and these usually require a power-off brake.

Other designs such as grounds-maintenance carts for cutting grass, vehicles for solar-panel cleaning, and security cars must drive up and down steep slopes (exceeding ±30°) and run in fully autonomous mode. At their heart, these are motion designs, Shearer noted.

“We’ve also catered to these growth industries by providing dc-power drives to accompany our motors,” said Peter Zafiro of LinMot USA. “Vehicle designers can just use their own chosen incoming power — even battery power … or use power coming off rails. Then off that incoming power, a dc bus power supply in the vehicle design can run our motors. This setup — small dc drives distributed throughout the vehicle — is much better than having a large (and heavy) three-phase inverter.”

This integrated traction-wheel assembly with steering from Allied Motion Technologies includes a right-angle permanent-magnet gearmotor. The gearmotor turns a pinion that rotates the wheel about its centerline. The small white pinion and blue sensor (circled in red) send feedback on wheel position to a vehicle controller.

Of course, the motors in autonomous material-handling equipment must be reliable. According to Sensata Technologies V.P. of industrial solutions Matt Lesniak, Sensata BEI Kimco frameless brushless dc motors satisfy that requirement and fit quite well into the tight footprints of robotic joints.

Frameless motors from Kollmorgen let robot builders make designs smaller and more precise. The motors work in robotic arms and joints, collaborative robots, and AGVs for picking and sorting as well as self-driving forklifts. The frameless motors integrate seamlessly with strain-wave gears, feedback devices, and servo drives to deliver lightweight and torque-dense motion solutions.

After all, too much power in robotic designs is unnecessary and detrimental; each motor should only deliver the power that’s needed for its specific axis. Zafiro confirms that many of today’s designs achieve that with brushless dc motors … getting higher resolution at lower forces because there isn’t a large motor power factor. Such designs require more up-front application work, but that extra effort pays off big down the line, said Zafiro.

“AGVs for automotive assembly use our bldc transaxles on their traction wheels,” said Shearer. “AGVs for aircraft assembly also use our bldc parallel-shaft gearmotors for their traction wheels … and some flatbed pallet-carrying AGVs could soon use our bldc motor wheels.” He cited other specific examples.

In rail-guided high-density storage installations (also called AS/RS installations) that often work alongside mobile robotics, his company’s bldc gearmotors work on their traction wheels and surrounding conveyors.

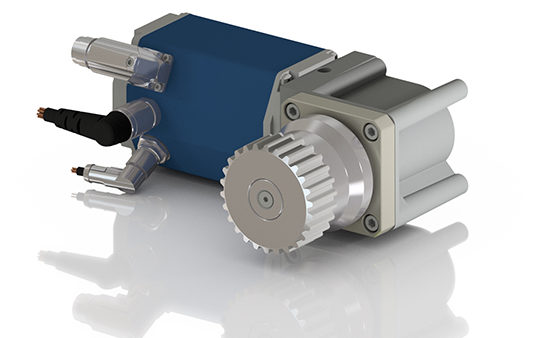

This mobility-robot wheel drive achieves a compact design and high efficiency with a brushless dc motor from Dunkermotoren and a specialty gear assembly from German gear manufacturer Framo Morat.

Though they aren’t autonomous mobile robots, increasingly heavy ATVs and UTVs as well as end-user demand for more luxurious riding experiences have spurred an uptick in electric power steering (EPS) and even steer-by-wire designs where the traditional steering linkage is omitted from these electric vehicles.

New forms of electric-motor actuation on construction, off-highway, and military equipment also abound. Some equipment for planting and harvesting now sports automated modules, so farmers no longer need to drive these vehicles. Where the efficiency gains and weight reductions justify the investment, many hydraulic applications are being replaced by electric on these vehicles as well.

Though not mobile (so beyond this feature’s focus) large-scale Cartesian arrangements in automated storage and retrieval (AS/RS) systems often complement mobile robotics in automated-warehousing installations. Image courtesy Dunkermotoren

Brushless motors in mobile robotics example 1: Allied Motion Technologies recently supplied a bldc gearmotor to replace a hydraulic actuator for opening and closing an armored door on a troop transport vehicle.

Brushless motors in mobile robotics example 2: The motor maker supplied an aftermarket bldc motor — with a controller — to couple to a steering wheel and autonomously drive farm equipment.

Brushless motors in mobile robotics example 3: One machine builder that makes a grape harvester is exploring the possibility of replacing their design’s hydraulic motors with electric onboard. The main reason here is that hydraulic motors and hoses can leak and contaminate food product.

Brushless motors in mobile robotics example 4: One new electric riding lawn mower uses the manufacturer’s electric motors for its wheel and blade drives.

Mass customization is also pretty typical of the motion components and subsystems that go into autonomous designs. Often a top objective is to reduce the design’s total part count. According to Shearer of Allied Motion Technologies, some LiDAR systems employ his company’s dual bldc MegaFlux motors paired with high speed encoders — in a completely custom design.

“Another example of a totally custom motion solution is the seat actuator for a military vehicle. Our full system solution combines a brushless motor, drive electronics, a parallel-shaft gearbox, and a ballscrew,” he noted.

In cases like these, the manufacturer has had a lot of success modifying standard products with custom motor windings, electronics, and gearboxes to fit specific applications.

“Small to medium-size companies are entering the realm of robotics — creating innovative technologies for medical, consumer, and industrial industries,” said Tomer Goldenberg of Elmo Motion Control.

These smaller companies (unlike large robot manufacturers) don’t have specific sensing or feedback divisions, motion or servo divisions, or control divisions.

“These smaller robot makers rely on motion technology manufacturers to provide them with products and tools to simplify implementation of motion system designs … and reduce time to market,” said Goldenberg. “So turning to servo manufacturers that can provide full solutions one technology is highly advantageous for small robotic manufacturers,” concluded Goldenberg.

“We are also seeing lab-automation companies, consumer-product companies, and even startups develop moveable collaborating robots; these are reasonably smaller than the offerings of typical robot companies,” agreed Jonas Proeger of Trinamic Motion Control. “Most of these designs focus on helping humans with repetitive or heavy-lifting jobs … and all aim to have teachable functions so the robots don’t need to be programmed — and anyone who can do a job can also teach the robot to do it or assist in that job,” said Proeger.

Power-transmission designs are also tailored to AGVs

The varied designs of AGVs and mobile robots also necessitate specialized drivetrains. That’s according to president of GAM Enterprises Craig Van den Avont. His company has supplied custom reinforced gearbox subassemblies that are capable of high load bearing (to support the weight of an AGV) even while fitting into compact vehicle wheel hubs.

Here’s one of the challenges: The way in which vehicle weight rests on the wheel drive shaft makes for significant radial loading on the assembly’s bearings. Standard groove ball bearings installed in close proximity don’t fit the bill. That’s because wheel loads on nonspecialized assemblies cause output-shaft and gear deflection, which in turn accelerates wear. Pretensioned tapered-roller bearing pairs do resolve hefty radial loads but are relatively heavy and degrade efficiency — unacceptable tradeoffs for designs running off battery power.

Another solution to this problem from German gear manufacturer Framo Morat is a narrow wheel-hub gear design using standard ball bearings to absorb vehicles’ radial loading on the wheel assembly. Within its gearbox, a motor-input shaft and hollow drive-output shaft are concentric … so radial forces through the hollow shaft are centered between twin ball-bearing supports. Tight clearance between these bearings maximizes the output shaft’s bending stiffness.

Of course, not all mobile designs have a four-wheels-and-a-car morphology. Robot and AI supplier Autonomous Solutions Inc. (ASI) continues to offer their Chaos “high mobility” robot. It has four continuous tracks that are free to swing like arms — as if the tracks on a tank were cut loose from the tank body at an idler-pulley end. Here, eight Parker Bayside frameless torque motors drive these free-moving tracks to make them paddle over rocks, logs, and aquatic obstructions. Speeds are to 6.5 mph and continuous load capacity is to100 lb (or 275 lb with slightly limited capabilities) for real-world applicability in surveillance, mine exploration, explosive ordnance disposal (EOD), and other dangerous missions.

Chaos robot image courtesy Autonomous Solutions Inc. (ASI)

GAM Enterprises has also supplied subsystems for these kinds of automated designs. In such rough outdoor terrains, the way in which vehicle wheels traverse rocks, curbs, and mud necessitates specialized power-transmission subassemblies capable of withstanding significant shock loading.

But even in more controlled indoor environments, ruggedized wheel drives are helpful. “We currently see rapid rise in technologies bound for automated-warehouse applications, especially those destined for automated transport vehicles,” said Proeger. “These are occasionally on rails, but many designs run independently and on Mecanum wheels. None of these are projects we may name, though we know such designs are employed by industry leaders.”

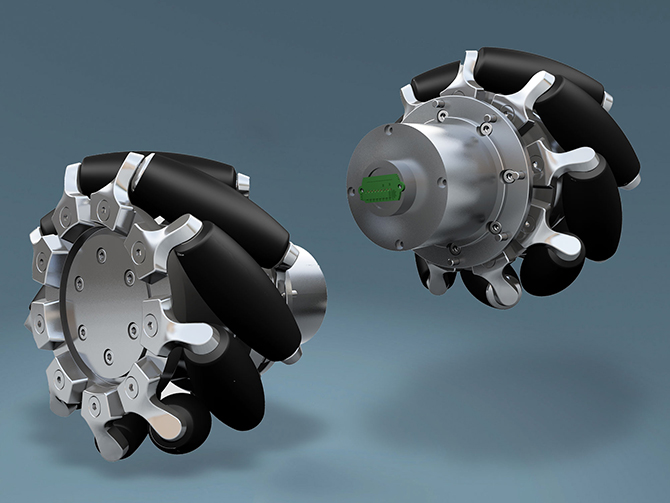

This is a customized drive unit from Nabtesco Corp. with a Mecanum wheel. Nabtesco offers compact RF-P series solid-shaft cycloidal gears for Delta and SCARA robots as well as AGV wheel drives. The two-stage RF-P series gears allow output speeds to 200 rpm and exhibit hysteresis loss of less than 2 arc-min., making them suitable for precision applications.

Omni-directional Mecanum wheels were invented in the 1970s and through the 1990s were primarily used by the U.S. Navy. The wheels are quite useful on transport vehicles such as AGVs, as they allow motion in any direction without a turning circle. That makes for nimble moves in confined intralogistics installations as well as settings where mobile robots must navigate around lots of conveyors.

Like omni wheels (a fairly similar design) Mecanum wheels are now manufactured and employed by a wide range of OEMs and organizations, including FIRST Robotics teams on educational-grade robotic vehicles and those building far more sophisticated industrial designs as well.

In fact, another design challenge for the wheel drives of AGVs and similar designs is that axially installed electric motors with multi-stage spur or planetary gears (common in conventional wheel and belt drives) are often too large. So to address this problem, one customizable and compact wheel drive includes a brushless dc motor from Dunkermotoren and specialty gearing from Framo Morat mentioned earlier.

The planetary gearing complements electronically commutated (brushless) dc motors from the BG series of Dunkermotoren; a bevel gearbox connects motor to hub gears’ input shaft for a very power-dense wheel drive. Motor efficiency of better than 90% and lightweight low-loss gearing maximize efficiency. The Dunkermotoren motors run off 10 to 60 Vdc; versions accepting 24 V can output 1,100 W and 2,600 W intermittently. Built-in speed control and positioning electronics are also available. Optional safe torque off (STO) functionality via software on its motor control can protect nearby personnel and machinery where needed.

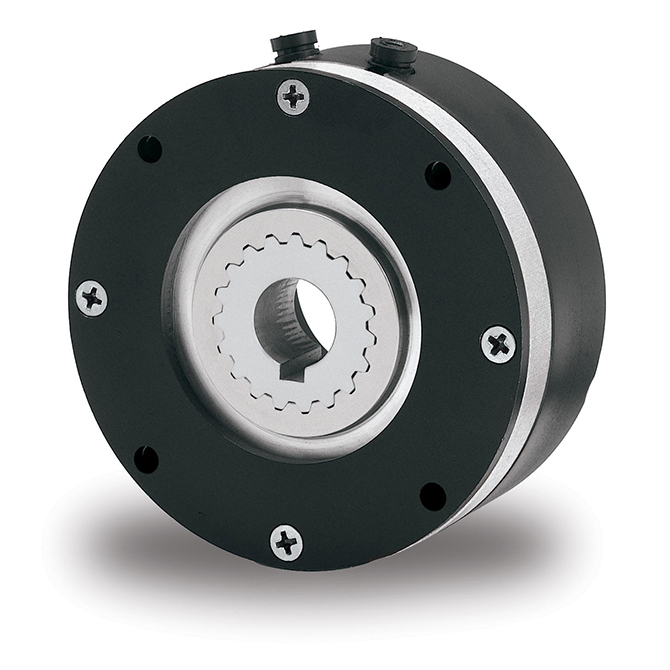

Battery-powered mobile equipment employs motion components such as those from the Electric Clutches and Brakes Group of Altra Industrial Motion. This manufacturer’s AGV ERS Brake for static holding with limited e-stop braking is for OEMs wanting to incorporate brakes and clutches with features to eliminate manual processes and maximize mechanical control of automated tasks.

Other motor suppliers supply complete wheel assemblies to the AGV market as well. Design World has covered the Wittenstein iTAS in the past; this modular servo-driven wheel axis has twin servomotors and helical planetary gearheads that accommodate Vulkollan wheels — not unsimilar to the Vulkollan wheels on the Framo Morat and Dunkermotoren offering. The iTAS motors allow wide tilting moments and have high power density to serve on AGVs that move especially heavy trolleys around.

Filed Under: Warehouse automation, Automotive, Gears • gearheads • speed reducers, Motors (direct-drive) + frameless motors, Robotics • robotic grippers • end effectors, Motion Control Tips

Tell Us What You Think!