There’s an untapped automation potential for palletizing goods in production and other industries. Realizing this potential requires flexible, easy-to-use, and affordable cobot solutions that can adjust to different palletizing setups and generate rapid return on investment.

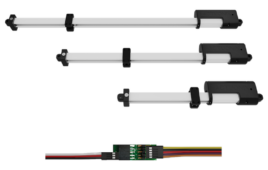

To meet these demands, LINAK now offers the ELEVATE lifting column — a new product that extends the reach of cobot palletizers in height where it’s especially relevant. It also delivers on speed, flexibility, and precision to optimize the palletizing process and ease the setup, programming, and monitoring of the system.

“ELEVATE extends the reach of cobot and enables it to palletize higher. This not only optimizes the stacking process, it can also reduce freight costs as each pallet carries more goods. With ELEVATE, we tailored a lifting column for cobot palletizers with focus on fast lifting speed, interfaces, stability, and compactness. The fact that it can be combined with a regular cobot makes it an affordable solution,” says LINAK business development manager Heiko Kleineder.

New levels of cobot performance

With its fast-lifting speed and optional simultaneous run, ELEVATE boosts a palletizer to match the cycle time of the production line. The lifting speed is constant with up to 100 mm/sec. and independent of load. With a brushless motor and an integrated controller, ELEVATE provides high position accuracy. Proven slider technology keeps the cobot steady and able to withstand high bending moments while moving.

ELEVATE fits into multiple palletizer designs

The integrated controller allows for compact size and eliminates the need for external control boxes. This makes ELEVATE extremely space-saving and easy to integrate and even reduces the complexity of the whole palletizer system.

Three interface options – ELEVATE Easy, Pro or Modbus – offer the level of control and feedback needed by a specific task, and data enable smooth troubleshooting, diagnostics, and optimization of performance. Due to these interfaces, ELEVATE is compatible with a wide range of cobots. Accessories like cobot mounting plates make it easy and fast to set up.

“ELEVATE comes with an accessory kit for easy setup. The kit includes mounting plates, cables, and in individual cases a cobot brand-specific driver software, such as a URCap for cobots from Universal Robots. Furthermore, one can use ELEVATE with preferred power supply and safety relay. This makes ELEVATE an adaptable component within multiple palletizer setups,” says LINAK product manager Markus Hofmann.

The Danish system integrator BILA A/S is one of the design engineers that got to test the product before launch.

“Our experience with the ELEVATE lifting column has only been positive. it’s easy to set up, and the intuitive software plays a key role, as it enables fast configuration as well as re-configuration. This is important in productions, where the setup isn’t permanent, and needs can change. In modern productions and warehouses, we see a trend towards automated palletizing, and with increasing freight costs, palletizing in height has become vital. These are some of the reasons we’re excited about the ELEVATE column,” says BILA A/S is product manager Brian Spetzler.

For more information, visit linak-us.com/elevate.

Filed Under: Linear Motion Tips