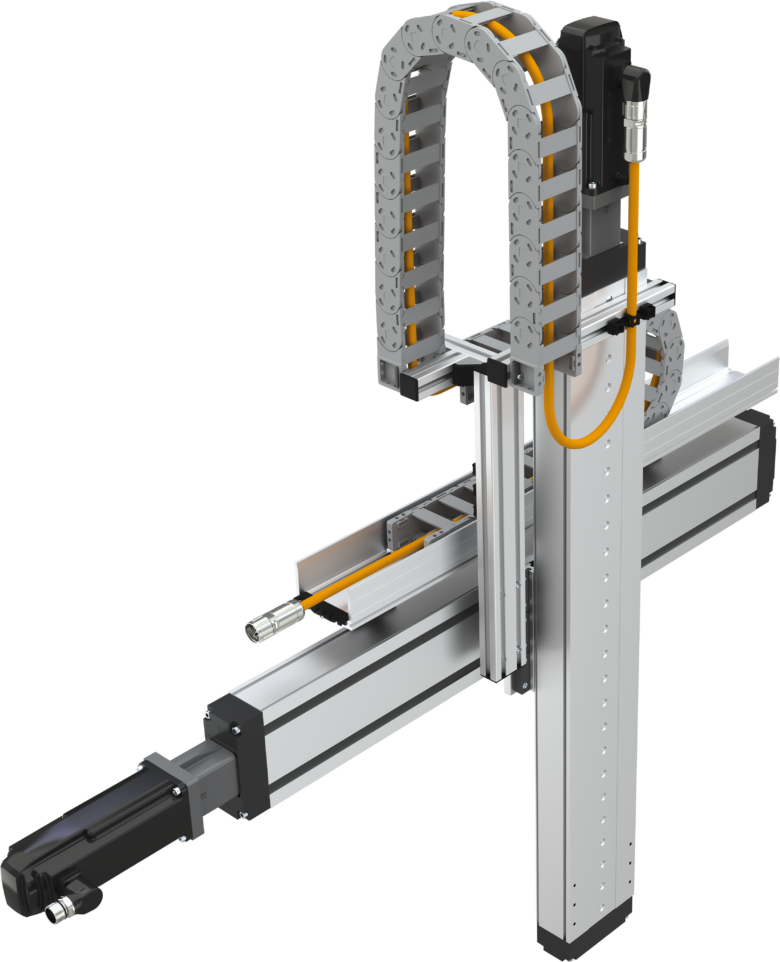

Bosch Rexroth has expanded its portfolio of linear robots for various applications in factory automation by adding new axis combinations and sizes. The much wider range of working areas and loads makes the Cartesian subsystems also suitable for applications like battery handling or intralogistics. The linear robots can be selected and sized quickly and easily thanks to predefined axis combinations. They can then be configured and finalized online and ordered as preassembled subsystems — optionally with controllers for the new ctrlX AUTOMATION platform. Each multi-axis system is also available as a Smart Function Kit for handling or dispensing. Preinstalled software then allows even quicker commissioning and intuitive programming. This significantly reduces the engineering time.

The expanded range includes eight different axis combinations with 68 sizes. The products can be used in a variety of sectors such as automotive (including battery production), pharmaceuticals, and FMCG. Applications range from pick and place, positioning, and palletizing to feeding, shifting, loading, and even dispensing tasks.

For use in intralogistics, including order picking and packaging, the new multi-axis systems cover large working ranges with stroke lengths of up to three meters in the X and Y directions and up to 1.5 m in the Z direction. The new load spectrum extends to up to 160 kg with three axes and up to 200 kg with two axes. The Cartesian robots are thus suitable for a range of tasks including handling individual parts, containers, and boxes.

The preassembled multi-axis systems with the Smart Function Kit option for handling or dispensing require little maintenance and achieve a high level of process quality and productivity. This is possible thanks to the special design properties such as rigidity, dynamics, and repetition accuracy and the new ctrlX AUTOMATION platform which is particularly suitable for complex movements.

The new single-axis solution will benefit robot integrators, by enabling a simple, additional linear axis for easy mounting of robots. This configuration allows the robot to move in a linear motion, rather than affixed in a stationary position.

The standardized procedure for selecting and sizing a suitable subsystem can be carried out quickly and easily using predefined reference processes with LinSelect. While the design is finalized in the online configurator, the 3D CAD data can be retrieved, an inquiry started or the system ordered via the e-shop. In order to minimize installation times, Bosch Rexroth supplies the selected robot system in preassembled form. If required, it can be supplied with a complete energy chain and cable management. To make commissioning easier, the relevant axis parameters are stored in the motor encoder memory and can be read out automatically. Various attachment parts and interfaces make assembly easier.

The software add-on for the Smart Function Kits for handling or dispensing saves users even more time. As part of the preinstalled software package, a wizard guides users intuitively through the commissioning process. The system is parameterized and the axes are referenced automatically. Sequencing is carried out on a visual basis with the help of ready-to-use functional modules and can be completed in just a few minutes. Thanks to the flexible combination of hardware platforms and innovative software, even complex line movements can be reproduced using simple graphic programming. Line integration can also be carried out easily with the help of suitable function modules.

Bosch Rexroth

boschrexroth.com

Filed Under: Factory automation, Motion Control Tips