ABB has launched its first range of rebranded Autonomous Mobile Robots (AMRs) following its acquisition of mobile robot leader ASTI Mobile Robotics in 2021. Since adding AMRs to its portfolio, ABB is the only company with a comprehensive and integrated offering of robots, AMRs, and machine automation solutions.

ABB’s full line of Autonomous Mobile Robots (AMRs)

“At a time when businesses are looking for a range of robotic solutions to help make them more efficient, flexible, and resilient, we are the only company supporting them with our integrated offering of AMRs, robots, and machine automation technologies,” said Marc Segura, President for ABB’s Robotics Division. “This is a game changer for our customers. They can work with one partner offering everything they need to adapt to the opportunities and challenges driven by individualization, labor shortages, and disrupted supply chains, and our rebranding underscores the simplicity and benefit of the integrated solutions we offer to our customers.”

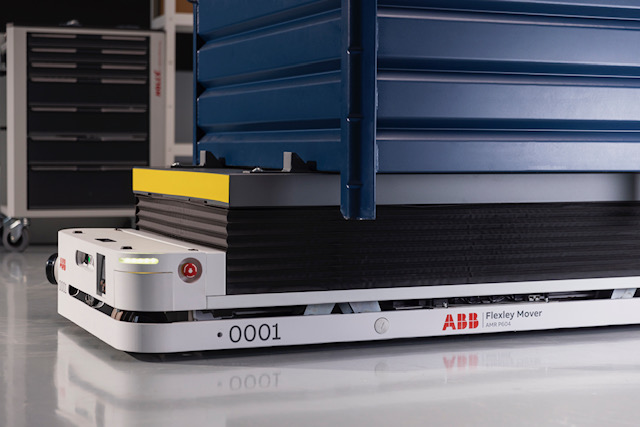

ASTI Mobile Robotics’ solutions are now rebranded and integrated into ABB’s portfolio, grouped under the Flexley name, indicating the flexibility of operations that the AMRs offer. The first models to be released, Flexley Tug and Flexley Mover, cover applications including towing, trolley transportation up to 2,000 kg, and lifting and transporting racks, containers, and pallets of 1,500 kg.

ABB Flexley Mover

Building on ASTI’s use of laser-scanner-based 2D SLAM navigation, the future ABB autonomous mobile robots will also benefit from pioneering VSLAM technology of Sevensense Robotics — a Swiss startup in ABB’s portfolio of partner companies — that enables mobile robots to navigate complex and dynamic environments. This unique technology opens new possibilities for flexible manufacturing — AI that makes ABB’s AMRs as autonomous as its robotic arms while making work more productive and safer for people.

“The market for autonomous mobile robots is set to grow significantly, with an annual growth rate of approximately 24% between 2021 and 2028,” said Verónica Pascual, Global Head of AMR business at ABB Robotics. “The integration of the ASTI AMR range and the creation of our global manufacturing and support network means we are well placed to address this growth, providing our customers with new ways to tackle their supply chain challenges and meet demands for greater flexibility and speed created by the continued rise in e-commerce.”

Already supplying AMR solutions for customer projects, ABB has worked with strategic partner Expert Technology Group in the U.K. to deliver a complete assembly line based on AMRs for a technological startup producing revolutionary products for EV vehicle drive trains. Transporting products between robotic automation cells and manual assembly stations, ABB’s automation solution combines the use of ABB robots, vision function packages, and AMRs.

The integration of ASTI into ABB includes a complete rebranding of all its offices and facilities, as well as the launch of a new website at amr.robotics.abb.com.

ABB

abb.com

Filed Under: Robotics • robotic grippers • end effectors