In a recent survey of industry experts, many mentioned Ethernet-based networking protocols overtaking traditional fieldbuses.

Recall that industrial communication protocols (including those based on Industrial Ethernet) are messaging systems for automated installations. Some fieldbuses are more reliable than nondeterministic Ethernet offerings, but Ethernet speeds now lead.

“Some old bus systems have data rates in the range of 1 to 20 Mbit and no real-time reaction,” said Horst Messerer, HELUKABEL data, network, and bus technology sales manager. “Certain types of manufacturing can tolerate these rates … so bus protocol won’t go away entirely — but they’re seeing reduced market share.”

In fact, industrial Ethernet-based networks now connect some 40% of industrial communication networks.

“That’s why more bus systems are being replaced with Ethernet-based equipment,” said Messerer. “The advantage of Ethernet is its faster data rate — with a minimum of 100 Mbit — which lets industrial-automation manufacturers view manufacturing and production process data in real-time. Having this kind of data quickly allows for improved reaction time to optimize processes for higher output per hour.”

Another benefit is that even though older variations such as 802.3c is slower than 802.3ab (at 1 Gbit/sec, which is called GbE) all use Cat5e cable. That makes Industrial Ethernet implementation easier. Both Cat5 and newer Cat6 cables for Ethernet work with Gigabit Ethernet, though Cat6 Ethernet cable is displacing the former.

“We’ve seen continued robust interest in both Cat5 and Cat6 flat cables,” said Rich Buchicchio of Cicoil Corp. “Our versions of these cables typically go in applications that benefit from high cable flexibility and durability to survive extreme environments better than common versions of these Ethernet cables.” The cables meet (and typically exceed) platform requirements.

Besides speed, other reasons for Ethernet’s rise include its ease of use, and ubiquitous design; multi-protocol network acceptance; familiarity thanks to commercial off-the-shelf (CotS) Ethernet; and consolidation of network-interface hardware. Plus unlike traditional device and fieldbus networks (that can have multiple physical layers) Ethernet networks run on one.

Controls and related motion hardware often dictate which fieldbus communications an installation will use.

“We continue development of integrated motors that can be powered over Ethernet (PoE),” said Eric Rice of Applied Motion Products. “Combining power and Ethernet over a single cable is an excellent example of the evolution of integration in motors, drives, and industrial Ethernet communications.”

PoE-enabled integrated motor offerings from the manufacturer include NEMA 14 and NEMA 17 frame motors.

Traditional industrial components feature Ethernet connectivity for an increasing array of functions. “Today, there are scalable I/O options for PLC control … and new hardware to communicate with remote I/O includes multi-Ethernet products to cover major Ethernet such as SERCOS, EtherCAT, PROFINET, and EtherNet/IP,” Joaquin Ocampo, product manager of motors and drives at Bosch Rexroth.

In fact, five real-time protocols — CC-Link, EtherCAT, EtherNet/IP, PROFINET, and SERCOS III capitalize on Ethernet advantages and deterministic networking.

The CC-Link protocol (supported by the CC-Link Partner Association) includes field-device, controller, and information networking and gets speeds to 10 Mbps at 100 m. Versions include CC-Link, CC-Link Safety, CC-Link/LT, and CC-Link Industrial Ethernet (IE) Control and Field. One CC-Link standard is a Seamless Message Protocol to let Ethernet-ready devices work on CC-Link IE networks. A new version of a Control and Communication System Profile (CSP+) simplifies integration of engineering tools and device profiles (in part by outlining the data necessary for setup and operation of CC-Link-compatible devices). Automation-component manufacturers primarily offer CC-Link functionality for servomotors, drives, robots, digital and analog I/O modules, and controllers including PCs and PLCs.

The Ethernet for Control Automation Technology (EtherCAT) protocol uses Ethernet and twisted-pair or coaxial cables with BNC adapters over distances to 1,000 m and optical cable beyond that. It gets Ethernet transfer rates and can control up to 65,535 nodes. Data processing through dedicated software and hardware allows deterministic communications. EtherCAT accommodates any topology and handles 1,000 I/O points in 30 μsec — capable of communicating with 100 servo axes in 100 μsec. Axes get values and control data and report position and status. A simple version of an IEEE 1588 distributed clock technique synchronizes axes with less than 1 μsec of jitter.

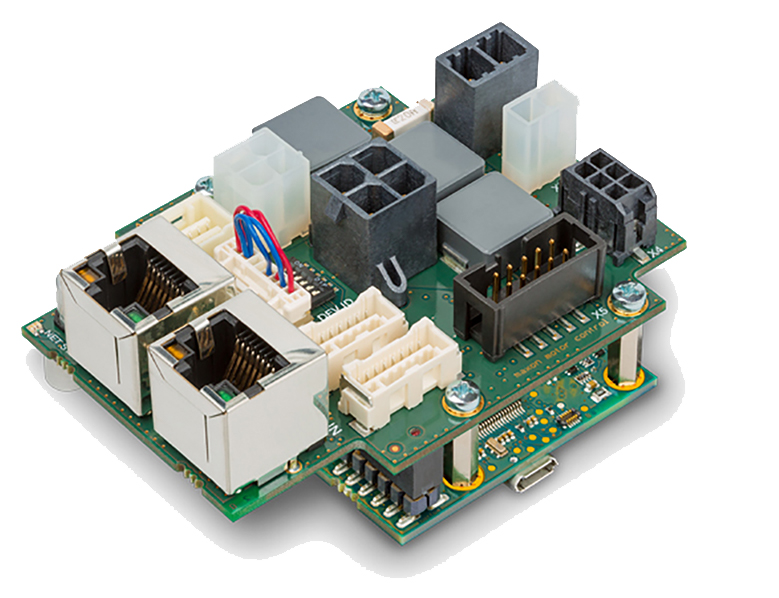

Shown here is a maxon motor EPOS04 Compact 50/8 EtherCAT smart drive-controller for programmable positioning.

Ethernet/IP is an industrial application-layer protocol for communication between industrial controls and I/O. It uses standard IEEE 802.3 TCP/IP and communications; Ethernet hardware pairs with TCP and UDP ports. Certain permutations enable synchronized and deterministic multi-axis motion control.

In fact, this and other industrial-Ethernet standards drive many product-development decisions that Applied Motion Products makes. “This year we enhanced our support for EtherNet/IP networks by introducing a set of improved Add-On Instructions for Rockwell’s RSLogix 5000 software,” said Rice. “We also introduced a new family of cost-effective motor drives for EtherCAT networks … and have begun development on drives and integrated motors for use on PROFINET networks,” he added.

Serial Real-time Communications System (SERCOS) is an open protocol for serial communication of closed-loop real-time data — over Ethernet cable for SERCOS III. Specifically for motion controllers, drives, actuators, sensors, I/O, the IEC-standard protocol closes servo loops in the drive to reduce motion-controller burden (and synchronize more motion axes than otherwise possible). Such closing of servo loops also avoids delays between motion controls and drives.

SERCOS III gets deterministic bidirectional real-time motion and control. It also enables higher-level I/O and transmission of conventional protocols over one Ethernet network in parallel with SERCOS real-time communication — with cycle times to 31.25 μsec.

PROFINET is from the same organization from the same organization that gave the motion industry PROFIBUS (PROFIBUS & PROFINET Intl. or PI) PROFINET use of Ethernet means larger messages, better bandwidth, and theoretically unlimited address space … as well as avoidance of network collisions. Deterministic communications are possible through real-time and isochronous real-time (IRT) operation. The latter gets update times down to 250 µsec, while PROFINET IRT gets them down to 31.25 µsec for synchronizing networked components.

Of course, industry-specific communication buses endure and even grow, as connectivity imparts design sophistication even to turnkey operation.

“Products with integrated industrial communications protocols simplify operation,” said Laura May of Thomson Industries. “For example, integration of J1939 CAN bus communications — most commonly used in mobile off-highway markets — means a system can programmed to let each of its actuators run with real-time awareness of speed and position of other actuators — enabling self-adjustment and deploying multiple actuators to handle heavy loads,” May added.

She added the manufacturer has work in progress to better support protocols commonly used in plant-floor automation.

Of course, an ever-growing (and cost-effective) array of gateways simplify network connections where J1939 CAN (and other buses) must interface with Ethernet. It’s common for fieldbus components to connect to Ethernet blocks for connectivity via Cat5E cable and Ethernet RJ45 connectors. Ultimately, Ethernet can even facilitate IIoT functionality to connect enterprise-level systems with machine, I/O, and device-level operations.

Ethernet-driven cloud-based IIoT along with (IEEE-802-compliant) wireless variations unify data streams for:

- I/O and motion communications and controls

- Safety functionality to protect equipment and personnel

- Diagnostics, machine-condition monitoring, and energy management

- Final product tracking and documentation of plant-operation statistics

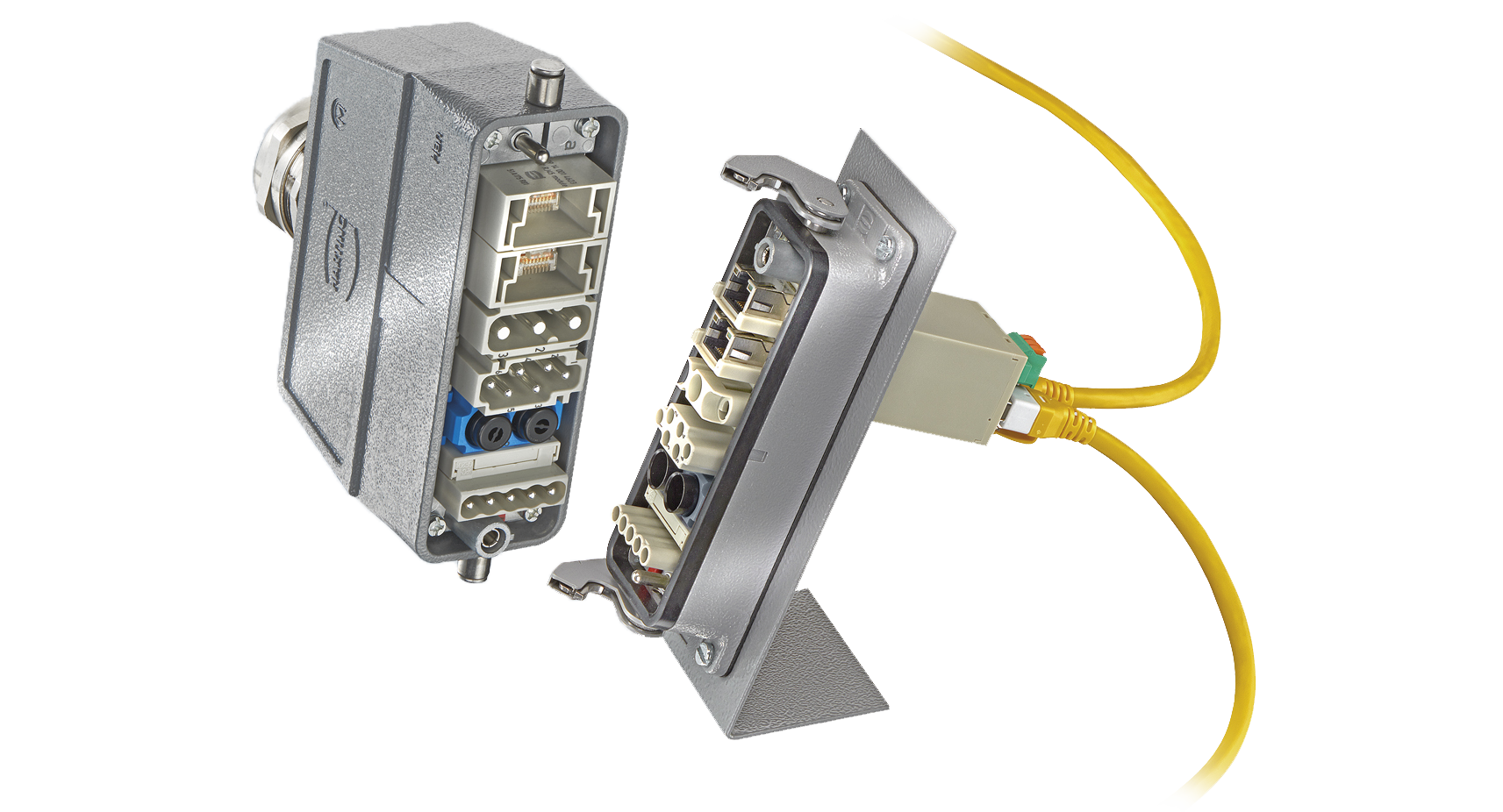

“One of three smart Han modules available is the Mini Ethernet Switch Module,” said Mark Kojak, V.P. of product management and business development in the Americas at Harting Inc., manufacturer of interconnect components. This module incorporates a four-port Ethernet switch within the connector. The module can replace or reduce the port count in systems needing a multi-port Ethernet switch … and excels in systems that use a daisy-chaining architecture.

Case study: Slip rings use CC-Link IE for gigabit data transfer

By John Wozniak, P.E. | Manager of CC-Link Partner Association (CLPA) Americas

Manufacturer of mobile electrification and data transfer systems for industrial machinery Conductix-Wampfler now uses CC-Link IE open gigabit Ethernet (GbE) for high-performance connections in its slip rings. Traditionally used to supply continuous power and data communication to equipment on rotating assemblies, the slip rings are for new and existing machinery needing Industry 4.0 data connectivity.

Conductix-Wampfler specializes in power, signal, and data-transmission systems for container handling, tunneling, mining, and bulk material handling. Their slip rings find use on rotating arms and gantries, cranes, wind turbines, manipulators, and cable reels.

As a CLPA member, Conductix-Wampfler has technical specifications to develop compliant product … even for custom connectivity solutions that work with Ethernet up to 1Gbps.

“Our slip ring technology excels in everything from industrial machinery to theme park rides … and we see need to transfer an increasing amount of data in a secure and easily accessible manner,” said product manager at Conductix-Wampfler Matteo Mosconi. So the company joined CLPA to focus on CC-Link IE because it’s the first and only open protocol that works at 1Gbps with real-time characteristics — and the organization that supports it offered the technical support Mosconi wanted.

“Slip rings certified for CC-Link IE can transmit power … as well as data at very high transfer rates.”

Founded in 2000, CLPA is an international open-network organization with more than 3,000 members (and the leading open industrial-automation network technology in Asia) dedicated to technical development of CC-Link open automation networks. Main activities include the development of CC-Link IE and CC-Link technical specifications; conducting conformance tests and development support. CC-Link IE is an open GbE solution for Industry 4.0 automation with unmatched bandwidth.

CC-Link Partner Association (CLPA) member Conductix-Wampfler used CC-Link IE open GbE technical specifications to develop compliant slip rings.

Filed Under: Slip rings + rotary unions, Motion Control Tips

Tell Us What You Think!