The international merger of two packaging powerhouses — Dublin-based Smurfit Kappa and Atlanta-based WestRock — creates a global supplier of sustainable paper and packaging solutions, operating in 40 countries with over 500 packaging converting operations and 63 paper mills. An official announcement of the acquisition was made September 2023. The completed deal was sealed with…

Angle sensor features four redundant outputs for safety-critical applications

TDK Corporation expands its tunnel-magnetoresistance (TMR) angle sensor portfolio with the launch of the TAS8240 sensor for automotive and industrial applications. This latest addition, available in both compact QFN16 (3 x 3 mm²) and TSSOP16 (5 x 6.4 mm²) packages, offers four redundant analog single-ended SIN/COS outputs and low power consumption. This sensor facilitates precise […]

Duravant expands processing equipment portfolio; launches aftermarket service network

Expanding its service offerings, Duravant, an Illinois-based OEM of packaging, food processing, and material handling equipment, recently announced the launch of Duravant Lifecycle Services. Designed to support its installed base of machines and integrated lines, Duravant Lifecycle Services is a global network of aftermarket organizations structured to enhance local delivery of all services, from purchase…

Why touch points matter to automotive design

Whether consciously or subconsciously touch points form the foundation for customers to perceive and make decisions regarding the products they choose. Touch points drive the quality of customer experiences, and serve as the basis for the resulting relationship. This is why it is so important to understand the impact that touch points can have on…

Emerson’s subscription-based automation reduces up-front cost and engineering complexity

Emerson has introduced the DeltaV Flex System, a subscription service that combines the DeltaV PK Flex Controller, term-based software licensing, and product support in a turnkey solution. The result, according to the company, is more flexibility for OEMs and process manufacturers that create small standalone systems, such as research and development labs, pilot programs, or…

Tech Toolbox: Machine design for food automation

Motion system designs run millions of automated food-manufacturing designs worldwide — including those in employed in grain milling, pasta making, and baking; fish and poultry processing; beer, wine, and spirit production; slaughtering and meatpacking; fruit, vegetable, and baby-food packaging, canning, jarring, and freezing; candy making; dairy and cheese making; and oils and fat extraction and…

Orion announces Kelly Watterworth as East Coast regional sales manager

Orion Packaging Systems has announced the promotion of Kelly Watterworth to East Coast Regional Sales Manager. Orion, part of the ProMach End of Line business, is a stretch wrapping and pallet unitizing machinery manufacturer of automatic and semi-automatic stretch wrapping equipment, including rotary turntables, rotary towers, and horizontal wrapping systems. In his new role, Watterworth will…

DevOps tools deliver source code quality control to industrial automation

Industrial engineers spend a lot of time writing code for programs that will run machines in the plant, on the packaging line, or in a warehouse. The problem is, however, there’s no standard best practices for version control or disaster recovery. Copia Automation, a four-year-old start-up, is changing that by applying IT-based DevOps to the…

Silicon Sensing accelerometer to equip in-orbit manufacturing demonstration satellite

Space Forge will launch ForgeStar-1, its in-orbit manufacturing demonstration satellite equipped with Silicon Sensing’s CAS291 accelerometer. This follows a program of testing and development in satellite vehicles. ForgeStar satellites will help produce advanced materials such as alloys, proteins, and semiconductors in ultra-vacuum and microgravity space conditions. These are the first satellites designed and built in…

Doosan Robotics unveils ‘PRIME-SERIES’ of collaborative robots at Automate 2024

Doosan Robotics Inc., has unveiled its newest and most powerful P-SERIES (PRIME-SERIES) at Automate 2024, bringing to the world of robotics the longest-reaching cobot to date. Today’s P-SERIES announcement by Doosan Robotics was marked by a show floor unveiling of the new P3020 – the world’s most powerful cobot for palletizing in existence. The P3020…

Finding the Right Formula for Flexible Food Packaging

To understand the future of flexible food packaging, you first must understand the history. No one knows that better than Tom Dunn, a 40-year veteran of the packaging industry who has developed flexible packaging products, processes, and platforms. Now, the managing director of Flexpacknology, he consults with manufacturers, material suppliers, and machine builders on how…

TurboChef adopts LeanDNA supply chain software to improve inventory management

Middleby Corporation is the parent company to several OEM divisions offering equipment for commercial foodservice and industrial food processing, including bakery and packaging applications. TurboChef, which manufactures ventless, rapid-cook ovens, is part of the Middleby business portfolio. To gain more control over inventory management and improve on-time delivery, TurboChef is now working with LeanDNA, a…

Automotive electric-actuator market trends

Automotive electric actuators adjust engine settings; manage safety features; and impart precise control fuel efficiency. Many such actuators are compact and light, fitting well in modern cars and requiring less maintenance. Some can be programmed to execute different tasks. The market for these automotive actuators is likely to grow at a moderate pace and reach…

Boeing announces exclusive distribution agreement with Ontic at MRO Americas

Boeing will now distribute about 1,000 additional actuation and propulsion system products. Boeing continues to expand its exclusive distributor partnership with Ontic. Through a new 10-year distribution agreement, Boeing will add to its offerings the TRAS (thrust reverser actuation system) and PECU (propeller electronic control unit) product lines – approximately 1,000 actuation and propulsion system…

Caddi Drawer generates searchable 2D drawings, saving design time and procurement costs

When it comes to designing parts, it’s best not to reinvent the wheel. Imagine, as an engineer, spending hours, days, or even months designing a part, only to find out later that it already exists. Unfortunately, it’s all too common, especially in machine building and manufacturing facilities that have been operating for decades. The problem…

Tech Toolbox: Machine design for packaging

Packaging machinery uses cutting-edge automation, and it’s no wonder. Facilities that parcel products need to deliver high throughput, but modern consumers demand smart packaging in the form of no-fuss containers that protect everything from M&Ms to patio furniture. What’s more, there’s a continuous drive to customize packages and let consumer-facing companies wrap products for bulk…

Packaging machines that are safe by design

By Stephanie Neil When designing packaging machinery for adaptability, it’s important to understand how the controls and components impact the way the machine moves, and even more critical to ensure those movements — and the machine itself — are safe. The obvious safety mechanisms include adding emergency stop (e-stop) buttons that will shut down equipment…

Stainless steel: The gold standard for equipment cleanliness

The value of safety — both for protecting people from physical harm as well as end users and OEM machine builders from lawsuits — has spurred increased adoption of integrated safety into slicing, baking, and bottling machines especially. Of course, economic pressures must be weighed against sophisticated safety fixtures. Save for a temporary rollback of…

Pneumatics in food manufacture

Pneumatic actuation is ubiquitous in food and beverage-processing equipment because it outperforms electric automation for many tasks. Pneumatics have a lower upfront cost and higher resistance to harsh cleaning — both dry and wet. With minimal electrical or electronic subcomponents at pneumatic axes’ end effectors and points of application interactions, these delicate elements aren’t potential…

Considering enclosures to satisfy food-safety regulations

The Food Safety Modernization Act (FSMA) imposes world-class regulations using hazard analysis and third-party certifications to ensure food safety. What’s more, a CDC, FDA, and USDA Interagency Food Safety Analytics Collaboration is currently underway to more precisely pinpoint foodborne-illness origins (including those involving automated machinery) using modern approaches. Expansion of the FDA could boost the…

Where machine design intersects with FSMA rules

Remember that while U.S. food-regulatory agencies don’t directly regulate food equipment, they regulate its use to require cleanliness. As part of FSMA, the Preventive Controls for Human Foods Rule demands that all plants registered with the FDA prepare and implement written food-safety plans — or FSPs for short. These FSPs must identify and outline solutions…

Sanitation and safety for food and beverage equipment

Food and beverage equipment must be safe and sanitary. In fact, food safety in particular is a key factor that will drive ROI for food and beverage manufacturers in coming years. Consider some specific examples: End users of grain milling, pasta making, and baking equipment have increasingly prioritized equipment that is quieter than past iterations…

Improving ISR missions with Change-Bitrate-on-the-Fly technology

Intelligence, Surveillance, and Reconnaissance (ISR) missions are rarely executed in controlled laboratory environments — quite the opposite. The platforms — from airborne drones to terrestrial and underwater remotely piloted vehicles (RPVs) — that carry ISR payloads are often deployed in the harshest conditions and connected to users and operators over wildly inconsistent communication networks. The…

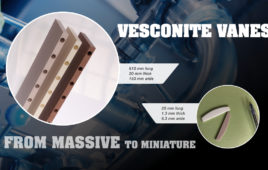

Cutting-edge manufacturing enables production of diverse vane sizes

Vesconite Bearings recently produced both the smallest and largest vanes in its history. This achievement underscores Vesconite Bearings’ commitment to engineering vanes in air motors, vacuum pumps and concrete vibrators to maximize efficiency, reliability and performance. In June, Vesconite Bearings successfully crafted the tiniest vanes to date, measuring a mere 1.3 mm in thickness, 6.3…

Spacecraft manufacturers use the force

Contributed by Keith Skidmore, Director of Custom Solutions, Sales, Interface When aerospace companies invest billions of dollars to build a spacecraft, they need assurance that their investments are protected. One of the key ways to do this is by force measurement, which provides test and real-time data on the feasibility and safety of lifting major…