Renishaw’s new TEMPUS technology enables users of RenAM 500 series metal additive manufacturing (AM) systems to reduce build times by up to 50 percent. The technology uses advanced scanning algorithms that sequence the layer data in a way that maximizes productivity while maintaining part quality. The optimization suits some part geometries more than others, but…

Compact and connected — 3D-Circuits revolutionize wearable medical devices

In the ever-evolving landscape of medical technology, innovation is not just a buzzword; it’s a necessity. Wearable medical devices have emerged as game-changers, providing patients with continuous monitoring and healthcare professionals with real-time insights. This requires the integration of reliable and sustainable electronic solutions. By integrating functions and the three-dimensional routing of circuit tracks, the…

New igus service: calculate the service life of 3D printing materials online in 30 seconds

igus has announced its online 3D printing service now enables users to calculate the service life of their printed wear-resistant parts. Knowing the durability of a 3D-printed component can help determine its service life more easily. This is why a service life prediction feature has been added to the online 3D printing service offered by…

New HP Automation Solutions advance 3D printing path to production at scale

News Highlights * New HP Jet Fusion automation solutions simplify workflows and reduce costs for high-volume 3D production. * HP expands materials, HP Digital Production Suite, and HP Digital Production Services for polymers and metals customers. * Go-to-market momentum includes new Digital Manufacturing Network Partners and Endeavor 3D adds HP Metal Jet S100 production capabilities…

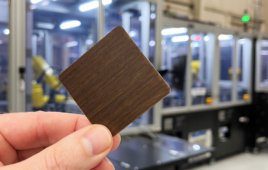

ARRIS unveils structural flax fiber composites

ARRIS, the advanced manufacturer enabling high-performance thermoplastic composites at scale for mass-market products and industrial applications, now offers a new sustainable fiber material offering. Sustainability and innovative material development are at the core of ARRIS efforts as the team scales Additive Molding for a production capacity in the millions to meet demand. Additionally, ARRIS has…

ARRIS increases additive molding production capacity to more than a million parts

ARRIS — manufacturer enabling high-performance composites at scale with new design latitudes for mass-market consumer products, transportation, and industrial applications — recently signed a contract manufacturing partner (CM) to further increase production part capacity. Additive Molding, a first-of-its-kind manufacturing, materials, and software technology developed by ARRIS, has been scaled from tens of thousands of parts in 2021…

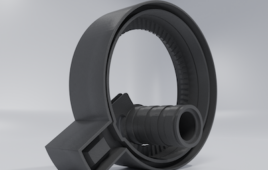

New laser sintering material from igus

igus, the leader in motion plastics, is expanding the scope of its 3D-print service. The company will now offer chemical-resistant, self-lubricating, tribo-polymer components that can be manufactured using selective laser sintering (SLS). This evolutionary step is made possible by a new printing material for laser sintering printers – iglide® i10. The new material is resistant…

Taking off like a rocket: metal AM for small satellite delivery systems

Humankind launched the first orbital satellite in October of 1957. Sixty-five years later, more than 5,000 satellites are in service, with roughly half of them placed into low earth orbit (LEO) over the past two years. Much of this activity comes courtesy of entrepreneur Elon Musk, whose SpaceX-launched satellite internet constellation Starlink will soon account…

Basics of printed circuit board milling machines

Specialized machines designed for prototyping printed circuit boards can drastically speed up development efforts. Leland Teschler • Executive Editor Examine advice columns online pitched at engineers and you’ll often see posts advocating an investment in a milling machine specifically designed to produce prototype circuit boards. Engineers who use these machines point to benefits that include…

September 2020 Special Edition: 2020 Additive Manufacturing Handbook

Disruption! The year 2020 will be remembered for many things: a global pandemic that disrupted global supply chains, digital-based jobs shifting from offices to Work From Home (WFH), shortages in needed medical equipment, not to mention disrupted economies, educational institutions, travel, and so on. So many systems have been upended. A bright spot, however, is…

The Decision-Makers’ Guide to Additive Manufacturing: Explore the essentials of today’s AM environment and improve your results

By Adam Kimmel Additive manufacturing (AM), also known as 3D printing, translates computer-aided design (CAD) data directly into a manufactured part, eliminating the drawing step and avoiding manufacturing tolerance mismatches. With a 2018 market size of approximately $8 billion, the technology is well-suited to meet the increasing market pressure to decrease sample lead times. Ideally, AM also…

Top 3 reasons why you should consider additive manufacturing today for production parts

By Tony Slavik, Applications Engineering Manager at FATHOM Additive manufacturing (AM) has been rapidly evolving into a powerful means of production. The additive technologies most commonly used for production of plastic parts include Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Multi Jet Fusion (MJF). To effectively utilize AM to produce end-use parts, it…

3D printing parts of an astronaut costume for Halloween

by Francisco Guzman, Technical Support Lead, GoEngineer This year my 3-year-old daughter impressed me with wanting to be an astronaut for Halloween. On her own, she started learning the unique characteristics of each planet, including how many moons they have and has even corrected me when I said that Superman is from the planet Krypton: […]

Women in engineering can potentially save lives — and the planet

Kimberly Gliebe is a chemical engineer currently working towards her materials science and engineering Ph.D. at Case Western Reserve University in Cleveland. We recently asked her six questions about her chosen career path. Here’s what she had to say. What first drew you to engineering? I think that it is hard to completely grasp what…

GE Additive and Oak Ridge National Laboratory sign cooperative research and development agreement

GE Additive announced that it has entered into a five-year cooperative research and development agreement (CRADA) with the US Department of Energy’s Oak Ridge National Laboratory (ORNL). The agreement focuses on processes, materials and software to drive industrialization and encourage the broader adoption of additive manufacturing technology. The agreement supersedes an existing CRADA in place […]

DSM and Twikit collaborate on end-to-end 3D printing solutions

Royal DSM, a global science-based company in Nutrition, Health and Sustainable Living, and Twikit, a Belgian 3D software and application development company, announced a new partnership. Their collaboration is a further extension of DSM’s ongoing commitment to build a 3D printing ecosystem, aimed at driving innovation in additive manufacturing and encouraging its adoption across industries. […]

RIZE adds Inceptra as value-added reseller

RIZE, Inc., an additive manufacturing company, named the largest Dassault Systèmes (DS) 3DEXPERIENCE solutions partner in North America – Inceptra, LLC – as a new Value Added Reseller. With this announcement, RIZE significantly expands access to its 3D printing platforms – RIZE ONE and full color capable XRIZE in North America, particularly to engineering and […]

Pittsburgh International Airport announces new epicenter of Additive Manufacturing

Pittsburgh International Airport on Friday announced plans for Neighborhood 91, a development to condense and connect all components of an additive manufacturing/3-D printing supply chain into one production neighborhood concept. Neighborhood 91, developed in conjunction with the University of Pittsburgh, is the first development of the 195-acre Pittsburgh Airport Innovation Campus and will be built […]

Global Additive Applications Summit to present 3D printing solutions

BigRep, the Berlin-based global leader in large-format 3D printing, has partnered with RedCabin, a tech conference expert consultancy, to host some of the world’s leading industrial companies using Additive Manufacturing (AM) based on 3D-printing at the exclusive Global Additive Applications Summit (GAAS) in the German capital on October 30 and 31. The high-level conference will […]

AM Engineers need a set of best-practices … and a change in mindset

By: Brian Crotty, Manager Marketing & PR, and Anna Schröder, Junior Marketing & PR at 3YOURMIND Technology advances alone are not enough to drive additive manufacturing into production workflows. But simple building blocks, such as best practices, management acceptance, and software to streamline production, can make the process of integrating additive into industrial manufacturing more […]

What HP has learned about working with 3D printing

Listen as Dave Woodlock, Market Development Manager at HP’s 3D printing group discusses lessons learned when incorporating 3D printing into your business as a product and as a tool. Notes Woodlock, many assume that what holds 3D printing back in terms of greater implementation is material, hardware, and so on. But what HP has found […]

What’s the difference between stereolithography and selective laser sintering?

Stereolithography and selective laser sintering are two very different forms of 3D printing/additive manufacturing technology. They have little in common other than building parts a layer at a time. First, these two systems build with different materials. Selective laser sintering, also known as SLS, sinters powder material (often a plastic in powder form) to form […]

New generation of linear motor stages from Yaskawa

The Drives & Motion Division of Yaskawa America, Inc. has added the Sigma Trac II series linear servo motor stages to the Sigma-7 servo family. Sigma Trac II combines a Yaskawa SGLF2 series linear motor with linear bearings, high-resolution absolute optical scale, cable management, and optional bellows to create a turnkey linear stage. Leveraging the […]

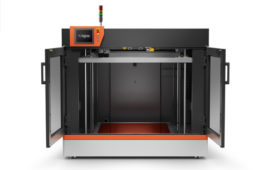

Stratasys new J850 3D printer builds parts up to 50% faster

Continuing to push the boundaries of 3D-printed realism, Stratasys unveiled the next-generation of its full-color, multi-material PolyJet solution – the J850 3D Printer. The J850 boosts speed and productivity for designers and engineers with more material capacity and faster printing while continuing the J-series’ reputation for high print quality and reduced time to market. Compared […]

New high-performance thermoplastics drive 3D printed tools and parts

Addressing the growing demands to deliver production-grade, custom 3D-printed tooling and parts, Stratasys unveiled several new durable, temperature and chemical resistant FDM thermoplastics. Meeting the specific requirements of 3D printed applications in manufacturing, these materials accommodate high temperatures and challenging requirements common on the production floor. Materials introduced include: –Antero 840CN03 for the Stratasys Fortus […]