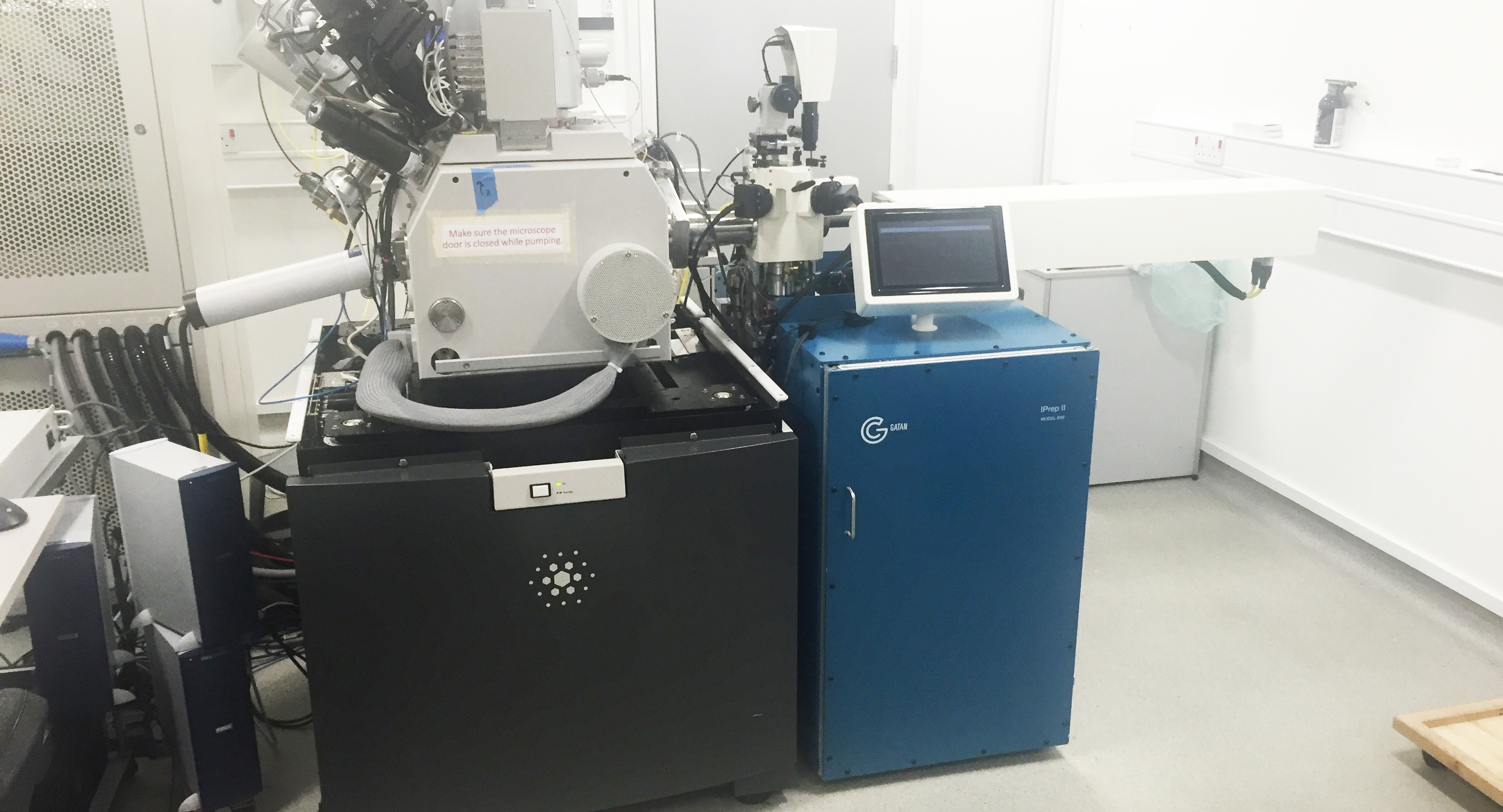

Gatan Inc. makes specimen-preparation equipment and recently built an alpha prototype of a new machine. The iPrep prototype mounts to a scanning electron microscope (SEM) and shuttles samples back and forth between a processing chamber and SEM receiving dock. Within the processing chamber, two broad-beam ion guns polish samples.

The iPrep’s automated transfer mechanism allows use of SEM-related imaging techniques for 3D reconstructions of sample areas with exact control over slice thickness.

This is Gatan’s alpha prototype of an iPrep machine that next to a scanning electron microscope. It is a high-vacuum-compatible receiving dock — one that can withstand E-6 Torr — with a kinematic mechanism that lets samples get mounted with accuracy to better than 1 µm every time. In this application, the workflow also consists of dozens of very specific operations … all needing reliable handling thousands of times. The iPrep from Gatan balances several parameters to deliver on these design objectives.

The iPrep machine employs an AllMotion controller to command a transfer arm’s end effector to accurately open and close … and move a sample carrier to the polishing chamber and SEM. Another AllMotion EZHR23EN48V controller is part of a kinematic mounting system on the receiving dock inside the SEM. Stepper motors drive the end effector and receiving dock.

AllMotion EZHR23EN48V controller+drivers have selectable step resolution from half stepping to to 1/256 steps … and can deliver to 20 million microsteps per second.

The EZHR23EN48Vs are controller-drivers measuring 2.25 by 2.25-in. and bolt to the backs of the stepper motors they control. The controllers use a single four-wire bus with two power wires and two for communication. Simple commands are made via any serial terminal program or from the EZStepper Windows application.

Because every operation the iPrep performs occurs in a vacuum chamber, it’s impossible to hear or see when things go wrong. So Gatan relies entirely on sensor data (leveraging EZHR23EN48V wiring for OptoSwitch inputs) to identify problems in the chamber. If this does occur, workflow is halted for maintenance.

The main specifications for the system lie in the repeatability of placement in the SEM. 3D reconstruction only works with very low shift and rotation between placements. “Our tolerance for shift between images in the SEM (after transferring) is on the order of several nanometers,” said Thijs Hosman, project manager and research scientist for Gatan. Plus incorporating shift detection algorithms can compensate for some of the shift between images … but the mechanical placement accuracy still must be on the order of 1 µm. The tolerance for rotation is about 0.05° between images. The distance between the preparation chamber and the SEM is on the order of 1 meter.

Filed Under: Motors • stepper, Motion Control Tips

Tell Us What You Think!