This webinar was presented live on Wednesday, November 14, 2018. Click below to watch it on demand.

Backstops are a fundamental safety component for preventing an uncontrolled change of direction and speed under the influence of gravity. A fully loaded, blocked belt conveyor system can impose huge torques on the drive. However, with the right know-how and an in-depth knowledge of the prevailing conditions of use, it is possible to design the backstop in a compact and cost-efficient manner and still safeguard the drive train reliably against overload. Backstops also merit closer attention from the point of view of technical aspects of occupational safety and health and accident prevention.

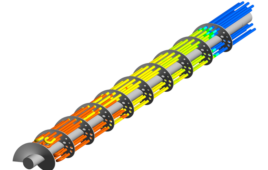

Until now, most types of backstops if they permit reverse running at all, do so to a limited extent, and certainly not at high speed. However, Stieber now offers products that no longer have this drawback. Operators of conveyor systems can hereby reduce stoppage times for belt unloading following a drive failure to a minimum. While conventional backstops have plain bearings, type RDBK and RDBR backstops from Stieber have a patented roller bearing assembly. They are thus able to run in reverse for a long time and most importantly, at high speeds.

By attending this webinar, you will learn:

- High-Speed and Low-Speed Shaft Designs

- Safe design of load-balancing backstops

- How to reduce stoppage times for belt unloading

Featured Speakers:

Anthony Turcato

Application Engineer

Altra Industrial Motion

Mike Santora

Editor

Design World

Sponsored by:

![]()

Filed Under: WEBINARS