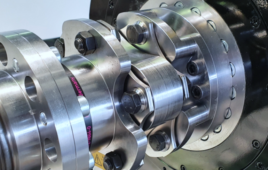

The couplings for a road construction sweeper require continuous, reliable performance while accommodating small amounts of misalignment.

Edited by Mike Santora

A manufacturer of industrial sweepers and brooms required an economical coupling solution for a line of road construction sweepers. Dual hydraulic pumps, horizontally mounted to each other off the rear of the machine’s 74 HP Tier 4 engine, drive the propulsion of the machine and control the operation and speed of the broom and various other components.

This coupling application required continuous, reliable performance while accommodating small amounts of misalignment. Dampening characteristics were also required to avoid transmitting vibrations into either the drive or driven components. The OEM used a standard SAE #4 engine housing with a standard SAE 10 flywheel connection. An SAE standard offset of 53.8 mm (2.12-in.) existed between the mounting face of the engine housing and the coupling mounting face.

The complete kit for this application consisted of a one-piece, all-steel FBA flywheel coupling, with a 4,640 in.lb. torque rating, that attached to the engine flywheel and mated to the hydraulic pump’s splined shaft.

The Guardian engineering team worked directly with the OEM’s engine distributor to configure a combination coupling and mount kit that installed easily onto the distributor’s engine package while accommodating the OEM’s specific performance requirements.

The complete kit consisted of a one-piece, all-steel FBA flywheel coupling, with a 4,640 in.lb. torque rating, that attached to the engine flywheel and mated to the hydraulic pump’s splined shaft. FBA couplings are torsionally soft and are designed for applications up to 450 HP. The kit also included an SAE standard flat steel pump mounting plate that attached to the engine housing and allowed the pump to be directly attached to it. The plate, featuring a special anti-corrosion coating, ensures that the pump is held in alignment with the engine housing and flywheel.

Guardian Couplings (Altra Industrial Motion)

www.guardiancouplings.com

Filed Under: Couplings