Canfield Connector, a manufacturer of high-quality electronic connection and sensor technology, has expanded their manufacturing abilities to save their customers both time and money.

Canfield has grown a reputation of providing high quality M8 and M12 connectors for sensing and automation applications.

In the past, previous designs have required the end user to design a solution for one side of the cable. But with the expansion of Canfield’s manufacturing capabilities, their team can provide a complete solution that meets and exceeds any competitor’s cabling solution.

“We knew that manufacturing the full patch cord solution was something that would benefit our customers, so we committed to making that possible,” said Michael Phillips, chief engineer for Canfield Connector. “We streamlined our pre- and post- molding process, pushing our tools to execute fast mold times while maintaining perfect finished products. We also had to make the transition to large capacity tooling.”

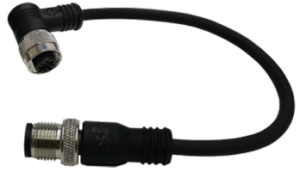

Canfield’s RP Patch Cords deliver a fully made in the USA solution to those needing a reliable connection to valves, sensors or automation of all types. Each connection is over molded to provide the highest level of anti-vibration and guaranteed to provide a safe and simple plug-and-go connection.

Each RP Patch Cord features robust nylon housing that provides shock and vibration protection while maintaining an IP68/IP69K (locked position) environmental resistance rating. Ordering options include various pin configurations, cable lengths and cable jacket options. For 8- or 12-mm connections, Canfield supplies an array of straight and 90° configurations with a pin option to meet every need.

All users will benefit from a cabling solution that is readily available and quality tested to ISO 9001:2015 standards.

Customers interested in this new offering are directed to contact one of Canfield’s authorized distribution centers.

Canfield Connector

www.canfieldconnector.com.

Filed Under: Connector Tips