The National Synchrotron Light Source II (NSLS-II) being built by Brookhaven National Lab (BNL) is a $912-million electron accelerator project scheduled to open June 2015. Research from NSLS-II will focus on developing the world’s next generation of sustainable energy technologies based on materials that have not been designed or fabricated yet. Researchers will be able to study the properties and functions of complex materials. An ultra-intense, highly-focused light is needed to probe increasingly smaller details of sample materials. When completed, the NSLS-II will be the only light source capable of providing scientists with nanometer-sized images.

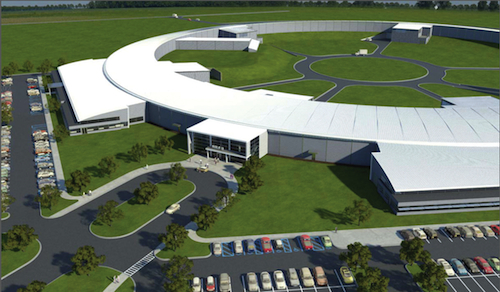

Rendering of the National Synchrotron Light Source II, currently under construction at Brookhaven National Laboratory. NSLS-II is a new state-of-the-art medium energy storage ring designed to deliver world leading brightness and flux. The facility will be able to produce x-rays up to 10,000 times brighter than those produced at NSLS today. (photos courtesy of Brookhaven National Laboratory)

The engineering team for the new synchrotron facility considered the major parts of the facility and what they would need to control them. The synchrotron produces light by accelerating electrons near the speed of light into a circular path controlled by a series of magnets. As the electrons turn, photons of light are given off as infrared, ultraviolet, and x-ray light, which is sent down pipes called beamlines to areas where scientists conduct their experiments. The major parts include an injector complex that generates and accelerates the electrons and is made up of an electron gun, linear accelerator, and booster ring; a storage ring that circulates the electrons while they radiate synchrotron light; and beamlines that transport the light to user experiments.

NSLS-II will accommodate approximately sixty beamlines using nearly 30 straight sections for insertion device sources. Although the synchrotron does not rely on motion systems for operation, experimental stations will depend on motorized systems to steer and focus their x-ray beams and to position detectors and samples. Each beamline will have an average of 100 motorized axes, which means that over the completed facility, there are expected to be 6,000 axes of motion.

826 high-precision magnets will form the main accelerator ring of the National Synchrotron Light Source II. A beam of electrons will be shot through the center of each magnet, where powerful magnetic fields will contain and steer the particles in a nearly circular path. Light emitted by electrons traveling around the ring will be shunted to beamlines, a collection of scientific instruments where experiments will be conducted. (photos courtesy of Brookhaven National Laboratory)

The Brookhaven engineering team is using repackaged Geo Brick LV multi-axis controllers designed and manufactured by Delta Tau Data Systems as the motion controllers. Delta Tau created a 19-in. rack-mount enclosure for the LV with connectivity specified by BNL. The motion controllers will accurately and repeatedly move several optical components that steer, shape, and focus the x-ray beams. The number, type, and location of these optical components will vary depending on the optical requirements of a given beamline. In general, all optical elements have some motorized degrees of freedom. Overall, BNL purchased 120 Geo Brick LV controllers to facilitate nearly 1,000 axes of motion.

The Delta Tau controllers will also play a key role in data acquisition systems on the beamlines as they will issue triggers to detectors at precise positions. The controllers may also be interfaced with other systems such as photon shutters where the controller will open and close the shutter.

The configuration will include the LV controller and the necessary axes boards, I/O boards, communication interfaces, and any other interface boards selected from the variety available from Delta Tau.

Basic motion control specifications include four or eight axes of simultaneous servo/stepper control with multitasking of up to 16 motion programs and 64 asynchronous PLC programs. All axes can operate independently or be coordinated in any combination. The controllers use a high-level programming language and offer a standard 128 K by 24 SRAM memory.

Delta Tau Data Systems

www.deltatau.com

::Design World::

Filed Under: Motion control • motor controls, ELECTRONICS • ELECTRICAL

Tell Us What You Think!