Finalists were announced on November 5th for the second annual LEAP Awards Motion Control Category. The competition was scored by a panel of independent engineering judges.

Below are descriptions of these worthy Motion Control finalists. The overall winner will be recognized at a ceremony in Santa Clara, Calif. in conjunction with the Healthcare Robotics Engineering Forum and DeviceTalks West events on December 9th. Information on how to register for the ceremony will be posted shortly.

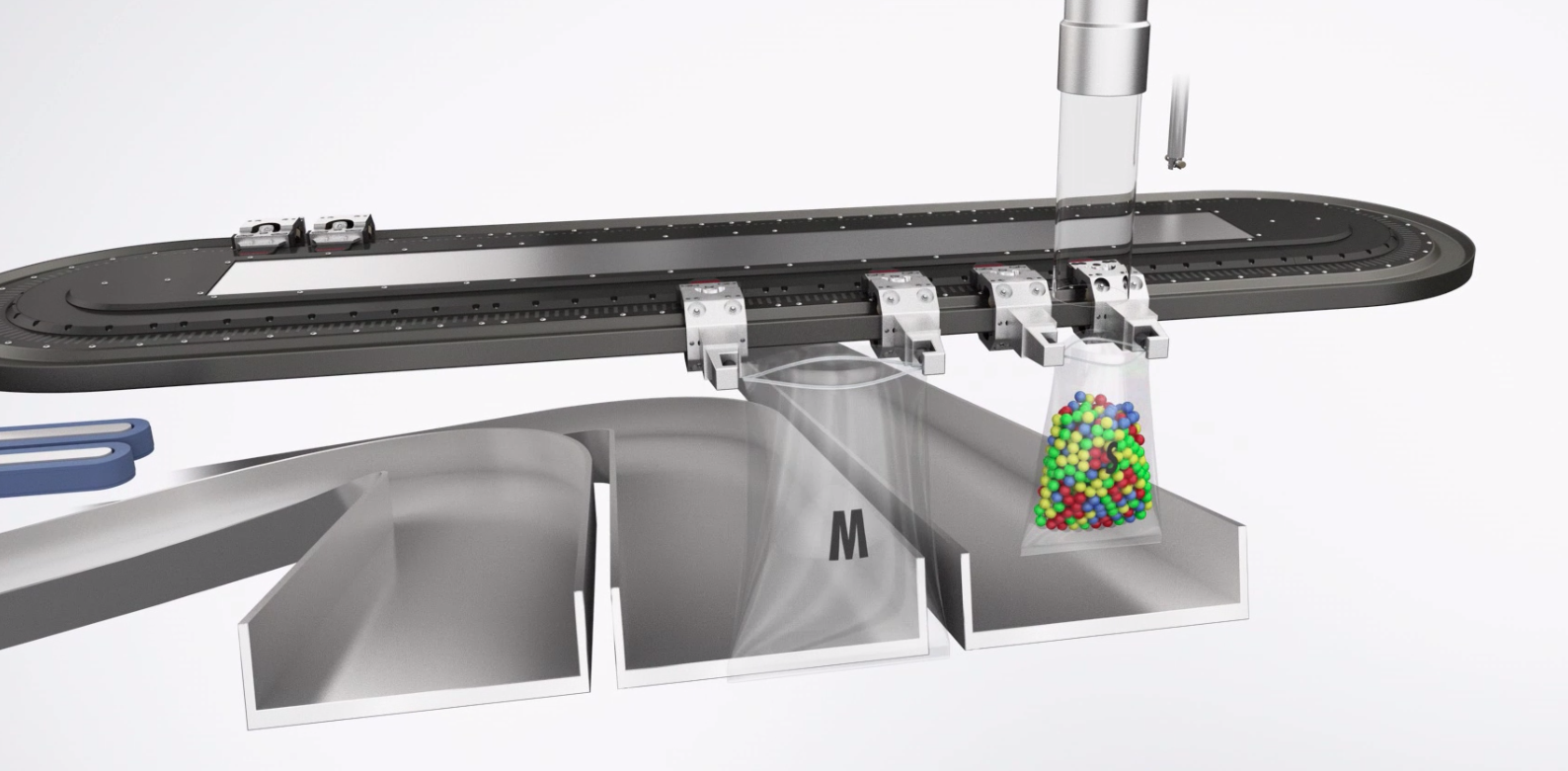

XTS mechatronic linear transport systems from Beckhoff

The eXtended Transport System (XTS) from Beckhoff Automation is now available. The EtherCAT-enabled XTS offers paradigm-shifting capabilities for motion control and mechatronics by combining the advantages of proven rotary and linear motion principles into a new modular platform. With its compact and flexible design, the advanced mechatronic system can reduce machine footprint up to 50%. The XTS revolutionizes drive technology and promotes innovative, globally competitive machine concepts.

XTS contains all functions necessary to support efficient integration for motion control applications in many industries. With attached mechanical guide rails, XTS motor modules feature directly integrated power electronics, EtherCAT communication and position measurement. An unlimited number of wireless XTS movers can be controlled with high dynamics at up to 4 m/sec on extremely customizable paths. By harnessing the flexibility and scalability of EtherCAT, PC-based control and TwinCAT 3 automation software from Beckhoff, XTS enables flexible mass production down to lot size 1 for the smart factories of today.

Houdijk Holland: Flex Skipper stack feeding machine for biscuits from Beckhoff Automation

The application possibilities of XTS are virtually limitless: Movers can accelerate, brake, position and synchronize themselves on the fly with automatic collision avoidance provided by TwinCAT 3 software. They can take up absolute positions and positions relative to each other; they can group themselves and accumulate; they can create clamping forces in motion, drive through curves and along straights, recover energy through regenerative braking and use both the return and outward paths for transport purposes.

Applications include those in packaging; food and beverage; pharmaceutical and biotech; assembly; robotics; and intralogistics and material handling. However, the system is particularly suitable for high-speed material handling to:

- Optimize irregular product flows to constant intervals and speeds

- Clamp and move products; pick up, transport, and discharge products

- Manipulate products — to lift out, close, rotate, or screw on caps

- Process products one at a time or in parallel in groups

- Integrate with robotics in real-time via EtherCAT

With unparalleled capabilities in the linear transport system segment, XTS offers leading-edge functionality and competitive advantages for users in many industries.

“The processing power of PCs keeps growing by more than a factor of 1,000 every 10 years. The question therefore arises: What new technological breakthroughs does this help us reach in the future? In addition, the EtherCAT industrial Ethernet system enables the transfer of large data quantities to PCs to fully use their potential,” says Beckhoff Automation senior product manager of drive technology Uwe Prüßmeier.

“Beckhoff moved away from conventional approaches and reflected on what features an optimal linear motor should offer from a user perspective. The main criteria seemed to be: any number of movers and continuous travel. It appeared technically feasible to control all motor coils centrally and to calculate all positions in the PC and control them from there. The computing power is affordable and the concept is manageable for the user. This led us to develop a mechatronic system. The XTS is more than just an IT effort. Mechanical engineers and electronics developers were also closely involved in the design process,” adds Prüßmeier.

Simple XTS motor modules form a complete unit with the movers and guide rails. The target geometries, lengths and radii are determined by the number and type of the components selected, with various options for 22.5-, 45- and 180-degree modules to enable circle, clothoid and S-curve designs as well as open straight segments. Motor modules contain electromagnetic coils and all other active functions necessary for operation. The only more requirements are a power supply and EtherCAT connection. Motor modules contain no moving parts and are thus not susceptible to wear.

The XTS movers contain magnetic plates that, together with the coils in the motor modules, generate propulsive forces. Movers absorb the attractive forces of the magnets on both sides and compensate for them. As a result, the rollers, composed of particularly low-wear plastic, can move at high speeds with acceleration greater than 100 m/sec2 … and a mechanically robust encoder flag communicates mover position to the motor modules.

Aerotech PRO-SV long-travel lift stages

Aerotech’s PRO-SV family of long-travel lift stages provides ultra-precise vertical motion in a low-profile package. Comprised of three models of varying travel ranges and sizes, PRO-SV offers the longest travel range available combined with the shortest overall height.

In addition to providing ample payload capacity, PRO-SV delivers excellent positioning accuracy, geometric performance, and minimum incremental motion performance. Each model features a large-diameter precision-ground ballscrew drive mechanism joined directly to a brushless cogless torque motor — thereby eliminating the need for belts, couplings, or gears. PRO-SV is guided by ultra-precise crossed-roller bearings. All stages feature a rotary encoder and can be equipped with an additional linear encoder for direct position feedback at the moving carriage.

Aerotech’s PRO-SV long-travel lift stage delivers ultra-precise vertical motion in a low-profile package. It offers the longest travel range available combined with the shortest overall height. In addition to providing ample payload capacity, the PRO-SV boasts the finest geometric performance available and a minimum step size. It also offers the greatest reliability of all ballscrew-driven lift stages.

The PRO-SV is suitable for applications with height restrictions or when multiple positioning stages may be stacked, such as beamline and synchrotron sample positioning and manipulation; wafer inspection; and surface metrology.

Lift-stage buyers have been forced to make tradeoffs between form-factor, performance, load capacity, stability, and longevity. Prior to the debut of the PRO-SV, it was impossible to find a lift stage that minimized these tradeoffs.

Aerotech’s PRO-SV long-travel lift stage delivers ultra-precise vertical motion in a low-profile package. It offers the longest travel range available combined with the shortest overall height. In addition to providing ample payload capacity, PRO-SV boasts the finest geometric performance available and a minimum step size. It also offers the greatest reliability of all ballscrew-driven lift stages. The PRO-SV’s key advantages include:

Process quality improvements: PRO-SV offers a long travel capacity with a short height. The short profile helps to minimize Abbe errors, resulting in better workpoint precision, higher production yield and improved quality. Further, accuracy and repeatability are optimized because the motor is directly attached to the ballscrew drive mechanism, meaning there are no belts, gears, or couplings to induce backlash or wear over time.

Increased precision: PRO-SV offers minimum incremental motion that is up to 10 times better than the next-best competitor. This enables users to process smaller features, inspect parts with finer resolution, and produce components with superior tolerances.

Greater process flexibility: PRO-SV offers a load capacity that is five times greater than the next-best competitor. This allows users to carry more durable, higher-quality payload axes (e.g. a rotation stage) and additional process equipment without worrying about overloading the stage.

Risk reduction: Because PRO-SV has no drive belts, gears, or couplings that need regular maintenance, and could ultimately fail, it offers superior reliability compared to competitive products.

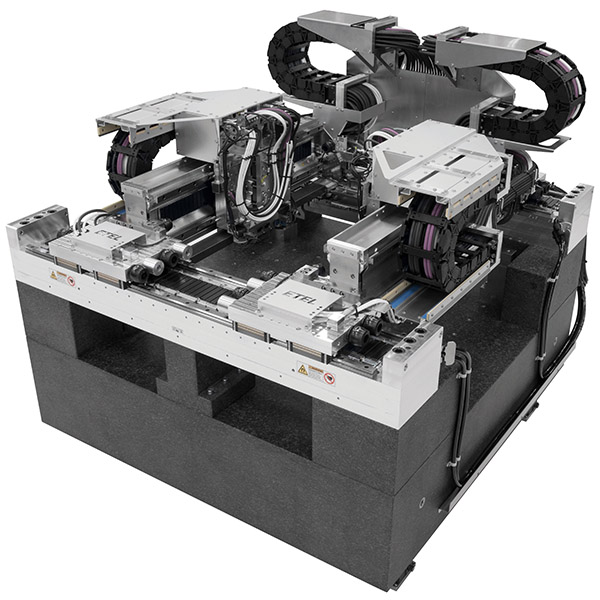

HEIDENHAIN ETEL TELICA positioning system

TELICA is ETEL’s newest positioning system promising to revolutionize motion control in semiconductor back-end processes. It lets users reach die bonding requirements of next generation advanced packaging by using a newly patented moving metrology frame (MMF) in the platform which results in an unusually high accuracy at a very high throughput — 1 µm global placement accuracy (350 nm local) over large panel substrates (720x 650 mm) at very high throughput (up to 10 kUPH).

TELICA has a dual-gantry architecture moving in X, Y, and Z directions. Powerful linear motors are water cooled to allow extremely high duty cycles along with accelerations to 60 m/sec2 while ensuring thermal stability for outstanding placement accuracy.

The TELICA platform’s integrated MMF acts as a dual position feedback loop at the process plane level, allowing real-time correction of the placement accuracy with no compromise on the throughput … and the MMF enables the metrology reference along the bonding process providing a stable placement accuracy at all machine working states — from cold start to thermal steady-state.

Coupled with ETEL’s state-of-the-art Motion controller, the TELICA platform benefits from numerous control features such as:

- Non-linear control as well as advanced feed-forward and trajectory filters

- Full synchronization of all axes with nanosecond jitter

- Specific gantry control mode

- Multi-dimensional mapping and advanced triggering capabilities based on real mapped position

- Advanced software diagnostic and system identification tools for control optimization

A 1-µm absolute positioning accuracy can be reached over the full panel size at full dynamics.

The TELICA platform is suitable for the following applications:

- Fan-out wafer-level packaging (FO-WLP); fan-out panel-level packaging (FO-PLP)

- TCB, C4, C2 die bonding processes; µ-LED bonding

- Any application calling simultaneously for throughput and ccuracy

The concept of a moving metrology frame (MMF) used in the TELICA system was designed for generally improving system placement accuracy — U.S. patent 2015/0280529 A1. The TELICA system integrates the concept with an improvement in that the metrology frame’s C-arm ends at the physical tool point — U.S. patent 2019/0063669 A1.

Thanks to the MMF concept, TELICA allows users to reach the die bonding requirements of next generation advanced packaging. For reference, a current state-of-the-art flip-chip die bonding machine can typically meet 7 kUPH at 10-µm placement accuracy or 3.5 kUPH at 5-µm placement accuracy. TELICA can meet 10 kUPH at 1-µm placement accuracy over a working space of up to 870 × 800 mm. The TELICA platform was released on July 2019 and exhibited publicly for the first time at Semicon West 2019 in San Francisco. The platform had been successfully beta tested and qualified by a major player in the die bonding world.

A very specific control architecture associated to the MMF makes the performance of this platform unique on the market.

The system was first designed as a functional model to validate the MMF concept and then as a prototype to fully qualify its performance. In parallel, numerical models were developed using finite elements and model order reduction to simulate and predict behavior thereby improving the design.

Conventional motion system design imposes a trade-off between throughput and placement accuracy, the first being inversely proportional to the second. TELICA is the only motion system platform on the market allowing a simultaneous combination of both placement accuracy and throughput. The platform also exhibits a very low thermal transient which translates into extremely short downtime. Typically, TELICA requires ten minutes to be back to full accuracy performance while more than one hour is necessary in conventional designs.

This combination of performance enables customers to face the challenges of the different fan-out processes and produce accurate packaging at higher rates than ever before.

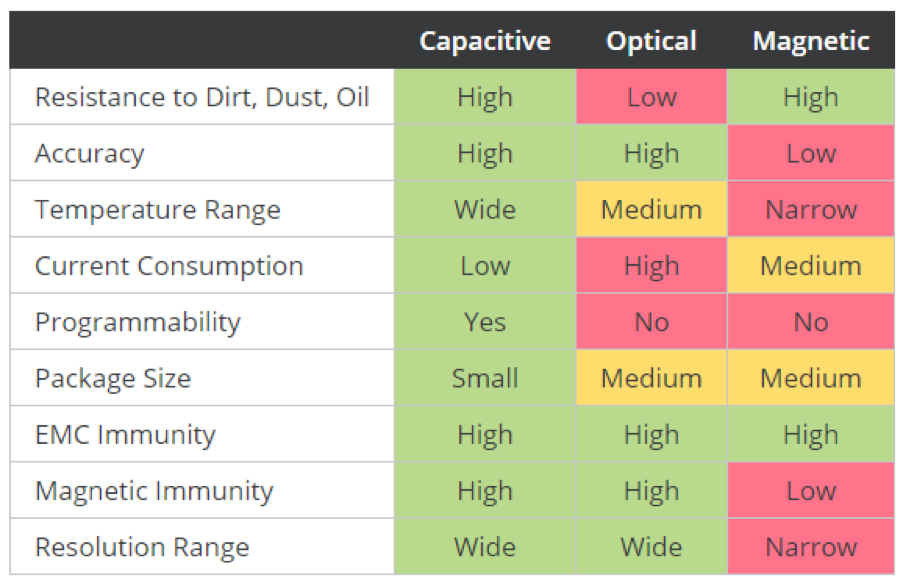

AMT33 commutation encoder series from CUI Devices

The AMT33 series from CUI Devices is a rugged high-accuracy commutation encoder that generates standard U-V-W communication signals for commutating brushless dc motors. Based on CUI’s proprietary capacitive sensing technology, the series combines high durability and accuracy with added resilience to dirt, dust, and oil that can plague other encoder technologies in industrial environments.

Housed in a 42.3 × 42.3 × 13.5 mm package, the series offers CMOS voltage or differential line driver outputs, low current consumption of 16 mA at 5 V, and a wide -40 to +125° C operating temperature range. This makes the AMT33 encoder suitable for industrial, automation, robotics, and renewable energy applications as well as battery-powered devices where energy consumption is a major design consideration.

| ENCODER MODEL | TYPE | OPERATING VOLTAGE | CURRENT AT HIGHEST RESOLUTION | POWER IN 4-MOTOR SYSTEM |

| AMT33 | Capacitive | 5 V | 16 mA | 0.32 W |

| Competitor 1 | Optical | 5 V | 85 mA | 1.7 W |

| Competitor 2 | Magnetic | 5 V | 160 mA | 3.2 W |

CUI’s AMT33 series using capacitive technology demands less than 10% of the power consumed by optical or magnetic types: Thanks to the digital nature of the encoder design, the AMT33 series incorporates a One Touch Zero feature — allowing for significant time savings during the motor installation process. Installing a commutation optical encoder onto a brushless dc motor (BLDC) can be an iterative and time-consuming process as the optical disk must be physically and precisely rotated to align with the correct motor windings. Once aligned, the assembly must then be checked via back EMF to ensure mounting accuracy … a process that can take upwards of 15 minutes per motor. The AMT33 (being ASIC and MCU based0 reduces this time-consuming process to a few seconds via the One Touch Zero feature, saving time and cost during the manufacturing process.

In addition to simplified assembly, the AMT33 is highly customizable with the ability to quickly configure the encoder’s resolution, pole count, zero position, and direction of rotation via CUI’s AMT Viewpoint software. This includes 22 programmable resolutions from 48 to 4096 PPR and 2, 4, 6, 8, 10, 12, or 20 pole pairs. The AMT33 series also supports 9 different shaft sizes ranging from 9 mm to 15.875 mm.

Whereas other encoders can typically only support a single resolution and shaft size per encoder, CUI’s AMT33 series supports over 2400 configurations under a single SKU. This gives engineers ultimate flexibility during development or production, while saving time and money without having to swap out an encoder each time a new configuration is needed.

The incorporation of diagnostic capabilities into the AMT33 series further provides the designer access to valuable system data that previously was not available in pure analog solutions. This data can be used to quickly allow the system to determine if the encoder is operating properly, has failed or become inoperable, or has become misaligned. The system can then use this data to inform operators of potential issues or to make informed decisions on its own before turning on the motor and causing potentially disastrous damage. This diagnostics data makes troubleshooting easier, while shortening or eliminating crippling downtime altogether. Unlike traditional analog encoders, the digital programmability and diagnostic capabilities of the AMT33 series makes it well suited for emerging IIoT and Industry 4.0 applications.

Derived from the same principles used in digital calipers, CUI’s capacitive encoder technology has an excellent track record since CUI launched the first generation in 2006. The AMT33 series has proven to be both highly reliable and accurate, solving many application issues experienced in optical and magnetic technologies. A capacitive encoder is more rugged than an optical encoder, tolerating a range of environmental contaminants such as dust, dirt, and oil. Capacitive encoders also hold-up much better to vibration and temperature extremes. Further, with no LED, it has a longer lifetime, a smaller footprint, and lower current consumption than an optical encoder. Immune to magnetic interference and electrical noise, it is as rugged as a magnetic encoder — but delivers greater accuracy and higher resolution.

Comparing the performance advantages of the AMT33 series’ capacitive technology versus other types:

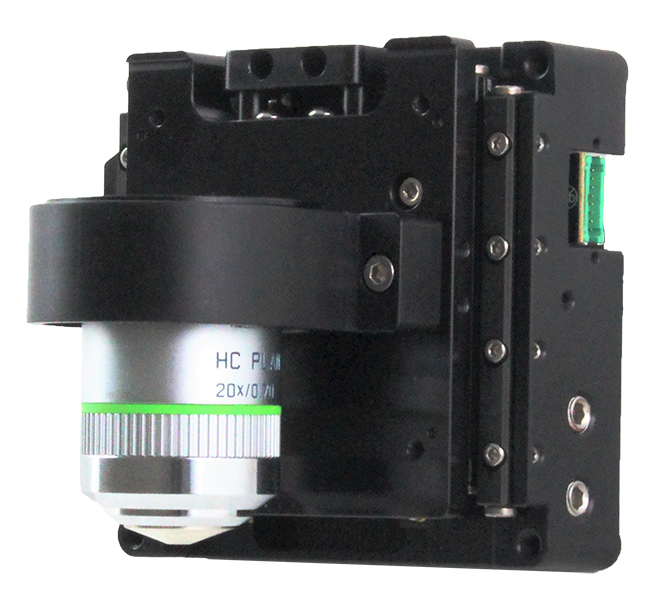

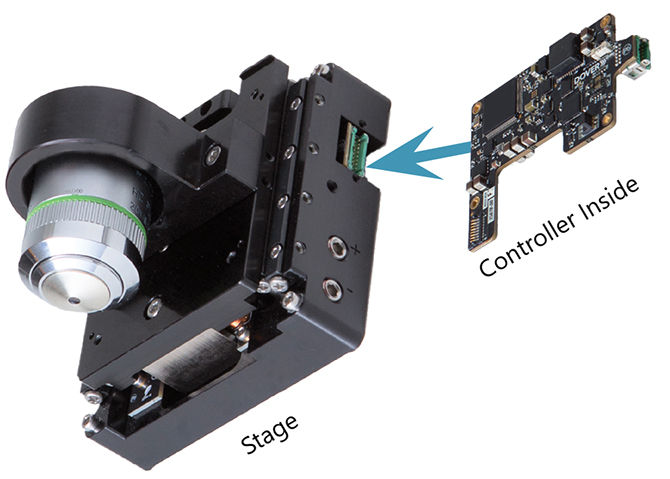

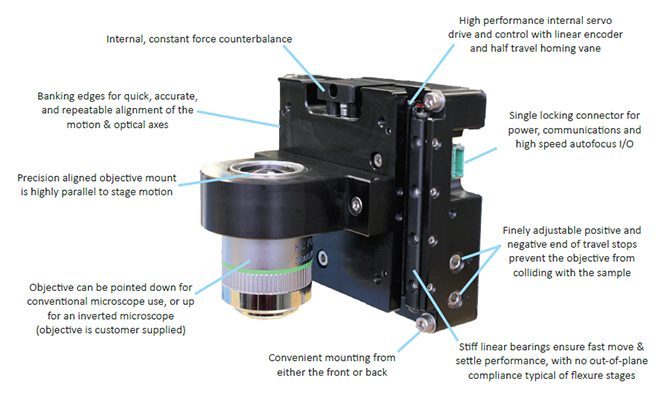

DOF-5 low-cost nanopositioning stage for imaging from Dover Motion

Life science and diagnostic instruments have seen a rise in the automation of processes that were traditionally performed using manual microscopes. The DOF-5 is for automated imaging instruments that focus a camera image by moving the objective.

Suitable imaging applications are:

Suitable imaging applications are:

- Diagnostic instruments with automated microscopy used for cell imaging (cytology); tissue imaging (histology) — for example, for cancer screening; and blood-cell imaging (hematology)

- Digital microscopes for university and life science research; DNA sequencing

- Nanotechnology inspection; semiconductor inspection equipment

- Metrology

The underlying technology in the DOF-5 is covered by U.S. patent 10367436 for a single axis linear motion system. This patent covers the novel implementation of a circuit board embedded within the structure of the stage that incorporates the position feedback, linear motor drive circuit, and motion controller.

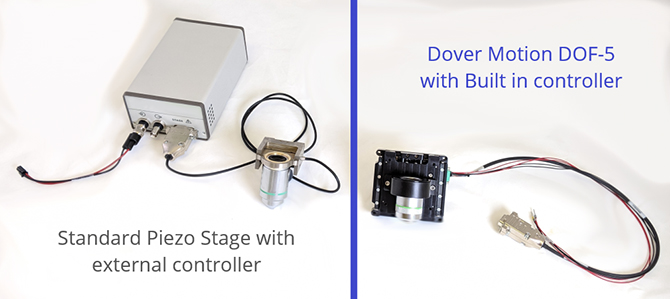

For many years, the industry standard for focusing has been a stage with a piezoelectric motor and flexure bearing. This technology has persisted despite its high cost as well as bandwidth and tuning issues — as well as short travel. The DOF-5 is a novel and disruptive nanopositioning product with a breakthrough price that delivers high performance and increased travel. The DOF-5 uses an integrated controller and stiff crossed roller bearings for superior performance at a price in stark contrast to the high price and limitations of piezo motor flexure bearing stages.

With the DOF-5, Dover Motion has solved several major customer pain points of high price piezo focusing stages, giving users a better and lower cost Z-axis focusing stage option for automated imaging applications which need objective focusing.

Despite their prevalence in the microscope focusing market, piezo-driven actuators have many limitations.

1. Piezo stages have very limited travel, typically only 0.2 to 0.5 mm. This drives very tight tolerances into the many parts in the structural loop between the objective and the sample. What’s more, piezo actuators are unable to clear proud elements on the sample carrier, or to assist in sample loading and unloading. They are also poorly suited for optically thick subjects, such as tissue samples.

In some systems, the very restricted travel of piezo stages leads designers to implement a “macro-micro” strategy in which the fine resolution piezo stage rides on an additional coarse-resolution longer-travel stage. This approach doubles the number of moving axes and increases complexity and cost.

The Dover Motion DOF-5 uses a direct-drive linear motor instead of piezoelectric actuation to provide more than 5 mm of travel (about ten times that of competing piezo stages) and adjustable hard stops. The increased travel eliminates the need for a secondary axis and hard stops can be set to prevent crashes which makes building instruments a lot easier. The travel range of the DOF-5 is great enough to eliminate the need for manual adjustment points used to align the focusing axis structure to the sample motion axes, which is common when using piezo stages. The DOF-5 also provides a longer stroke for focusing on thick samples, or complex samples which aren’t flat.

2. The typical piezo based focusing stage uses lever amplification and a flexure bearing to constrain motion, and this results in poor axial stiffness, low servo bandwidth, and slow step and settle performance. In contrast, the new DOF-5 linear motor stage uses crossed roller bearings instead of flexures. These bearings are stiffer, and therefore not as susceptible to off axis motion forces from other moving axes within an instrument. The higher bandwidth and stiffness of the DOF-5 is important because it directly correlates to faster throughput allowing a given instrument to process more samples per day.

3. Piezo focusing stages have a bulky controller and cabling for the motor and position feedback device which takes up a lot of space either within the instrument or in a control box. Dover Motion’s patented approach of embedding the position feedback and controls into the linear motor stage eliminates the extra cables and controller. The DOF-5 only needs a simple power and communications cable to operate.

Dover Motion has been using direct-drive linear motors in its stages for many years, but relied on pneumatic counterbalances when supporting vertical loads. Another innovation in the DOF-5 is the first implementation of a constant force magnetic counterbalance buried within the structure of the stage. This is an improvement by eliminating the need for an air supply which was previously needed for pneumatic counterbalances.

The unique architecture and innovations within the DOF-5 spur a much lower price compared to existing solutions. The currently available piezo based stages have a typical low volume (<10) sell price between $9,000 – $12,000 for the nanopositioning stage and controls. The DOF-5 provides equivalent or better performance for less than $4,000. The onboard controller also allows the stage to be connected directly to an Autofocus system for easy integration. The superior price and performance of the DOF-5 is changing the paradigm for objective focusing stages.

| Piezo flexure stages | DOF-5 objective focusing stages |

| Single unit price ~$8,000 – $12,000 with controls. | Single unit price starting at $4,400 with controls. |

| Flexure bearing results in off-axis motion and position dependent parasitic force. | Crossed roller bearing provides higher stiffness for faster moves. This results in increased throughput. |

| Stack or oscillating actuation have a non-linear response and bandwidth decreases as payload mass increases. | Brushless linear servo motor actuation provides higher servo bandwidth and a linear response for optical microscopy. |

| 2-500 μm travel requires precise alignment and an additional coarse axis when more travel is required. | > 5 mm travel makes alignment easier. It also helps avoid microscope objective crashes and provides enough travel to clear interferences. |

| Off-axis, complex controls are typically bulky and high cost. |

Onboard controls spur a lower cost of ownership due to less complexity and fewer cables. |

Consider one recent application: WDI Wise Device Inc. is a manufacturer of compact autofocus sensors, automated microscopy modules and end user infrared imaging systems. Previously, WDI had complex cabling and controls for their autofocus motion. The autofocus system sent correction information back to a controller which then had to interpret that correction and send a motion position command to the focusing stage. Now, the autofocus sensor can be connected directly to the Objective focusing motion axis. This simplifies the cabling, and controls system, and was done at a fraction of the cost of the previous solution.

“Dover Motion’s DOF-5 provides a great solution for single high NA microscope objective actuation. It provides all the benefits of piezo regarding speed and resolution with none of the limitations such as short travel range and ringing at a lower cost,” says WDI VP of sales and marketing Tedd Kelemen.

Filed Under: Motion Control Tips

Tell Us What You Think!