Recently, a number of encoder, sensor, and feedback industry experts answered several questions about trends they are seeing with these components and the industry more generally. Here’s what they had to say.

MEET THE EXPERTS

Bill Paczkowski | Senior product manager for PACEdge • Emerson

Robert Cachro | Program manager – growth and innovation • Dynapar

Samuel Orozco | Product marketing manager — electric actuators • Emerson

Stuart Graham | Business development specialist • HEIDENHAIN

Could you describe what sensor, encoder, and feedback trends you see and which you consider most significant?

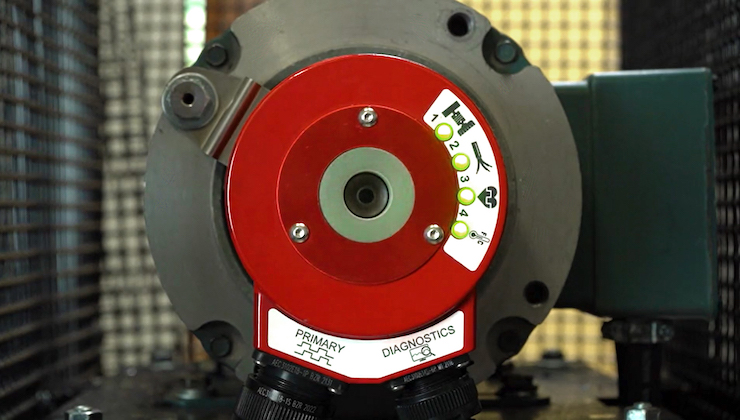

Cachro: Due to an aging workforce, limited availability of skilled labor, and increasing production demands to run at near maximum capacity, end users demand more reliable encoder solutions that maximize uptime and provide diagnostic data for reduced troubleshooting duration. At the same time, machine builders are increasing after-market support with field technicians or multi-tier remote support to help when customers experience issues with OEM equipment. As a result, we see a need for components that offer self-diagnostic capabilities that solve these pain points and provide immediate data at the problem area to help users know what to correct rather than guessing. With this in mind, our encoder solutions, such as the HS35iQ encoder, offer visual indication of specific fault conditions and advanced fault data output, allowing end users to fix problems without guesswork and enabling more efficient remote troubleshooting for OEMs.

Could you detail any recent examples of miniaturization or integration of feedback devices in compact designs?

Graham: In the encoder space, we are seeing more and more systems wanting to reduce overall size and cost by consolidating multiple components in one solution. Cutting-edge protocols such as EnDat 3 allow for daisy chaining encoder feedback over one cable chain, rather than each encoder running its own cable back to a controller. This is especially beneficial in robotics. Daisy chaining feedback reduces weight and cabling and ultimately provides increased cost savings. Robots can have as many as 12 or more encoder devices throughout the different robotic joints, end effectors, and base. With fewer cables, designers can reduce their robot’s weight and overall footprint.

EnDat 3 also supports a bus or hub architecture, in which different sensors can be directly connected and supplied back to the controller with one cable connecting the bus and the control. This enables time-stamped monitoring of multiple aspects of a machine at one time. The data can be modeled to determine a baseline during typical operation and help troubleshoot undesired behavior.

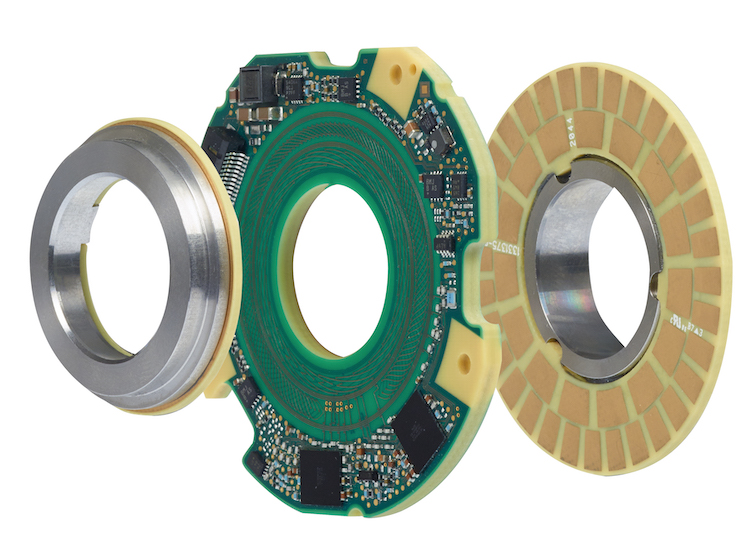

Designers are also able to further reduce the size and cost of robotic joints by using what’s called a 2-in-1 encoder. Typical robotic joints require an encoder on both the motor and the other side of a gearbox. The KCI 120 Dplus enables designers to reduce the number of encoders per joint from 2 to 1, resulting in a smaller footprint and lower system costs.

There’s an additional capacity to replace a torque sensor through the unique characteristics of the KCI 120 Dplus and how it mounts to the motor. By combining multiple features into fewer products, system designers can reduce costs and the required footprint of their designs.

Orozco: Miniaturization is a great benefit because it can reduce weight and space. For example, miniaturizing precise rotary-to-linear screw technologies can reduce power consumption on electric actuators and open new opportunities for semiconductor applications and medical automation equipment. Feedback devices such as encoders have improved over time. Servo motors have thrived on being able to have encoders that provide feedback regarding position. Enhanced stepper motors are closing the gap with closed- loop systems that allow encoders to also provide positional feedback. Linear motion end users benefit from enhanced feedback technologies that motors and encoders provide to actuators. End users can verify motor speed and motor position and help identify or detect motor stall.

How are increasing encoder capabilities spurring demand for higher-performance networking and connectivity options?

Cachro: A shift to reliable encoder solutions, which provide diagnostic data for reduced downtime and effective troubleshooting, will ultimately require additional higher-performance networking and connectivity options. Our latest encoder solutions allow customers to gather valuable insights from simple interfaces, such as visual indicators and digital outputs, without requiring them to upgrade existing legacy systems that are often unable to support additional data streams. However, the proliferation of data from “smart” sensors will ultimately drive the adoption of newer systems capable of handling this increased data throughput.

Do you supply any edge devices to allow for use of feedback or distributed control?

Paczkowski: Hardware at the edge can include basic sensors, intelligent instruments, field devices (such as smart solenoids and VFDs), gateways, PLC/PAC controllers, edge controllers, industrial PCs, HMIs, and more. Because each of these devices is different, they relate to each other and sometimes even overlap in functionality. There is no single device that addresses all digital transformation needs.

Emerson has developed a broad portfolio of technology encompassing all these types of devices, all coordinated with software and tested for compatibility. Using PACSystems computing devices with the PACEdge IoT enablement platform, users have a complete range of options to connect with, transport, store, analyze, and visualize data locally and in the cloud. Users can focus on their application needs, confident they are working with a platform enabling them to rapidly create buildable and supportable systems, which can scale from small pilot projects to full data integration solutions, while meeting IT and cybersecurity requirements.

What can you say about modular and user-formatted offerings?

Cachro: With increased machine complexity, the need to reduce inventory costs, and supply chain pressures, customers seek to consolidate inventory without exposing production to unnecessary risks due to component stockouts. As a result, we see a trend toward more programmable and customizable encoder options to consolidate multiple part numbers into a streamlined set of flexible encoders. Beyond encoder resolution, the ability to set encoder signal characteristics, such as index pulse location or phase, provides end users additional possibilities to achieve their inventory goals.

Filed Under: DIGITAL TRANSFORMATION (DX), Motion Control Tips