Encoder Products Co. now sells a new Model 30MT — a 30-mm diameter magnetic encoder module. By means of advanced sensing and signal processing technology, the Model 30MT provides accurate incremental feedback, even in harsh operating conditions. With its threaded housing, the Model 30MT is simple to install. See the unboxing video for an overview.

Encoder excels in harsh environments

Encoder excels in harsh environments

Designed for tough industrial environments, the Model 30MT offers sealing up to IP69K and is virtually impervious to dust, dirt, and moisture. The Model 30MT features a chemically inert high-temperature nylon composite housing and non-contact magnetic sensing. The encoder is capable of operating in temperatures from -40º C to 120º C and features a threaded housing for easy installation. With a generous sensor-to-magnet air gap of 0.022 in., the Model 30MT holds ratings of 100 g at 11 msec for shock and 20g at 10 to 3,000 Hz for vibration.

Encoder uses high-performance magnetic sensing

Even with its tough housing, the Model 30MT features signal-processing circuitry that allows for a wide sensor-to-magnet air gap while still providing excellent waveform symmetry and repeatability … delivering signal accuracy exceeding that of many magnetic encoders. Suitable for high-performance applications, the Model 30MT offers:

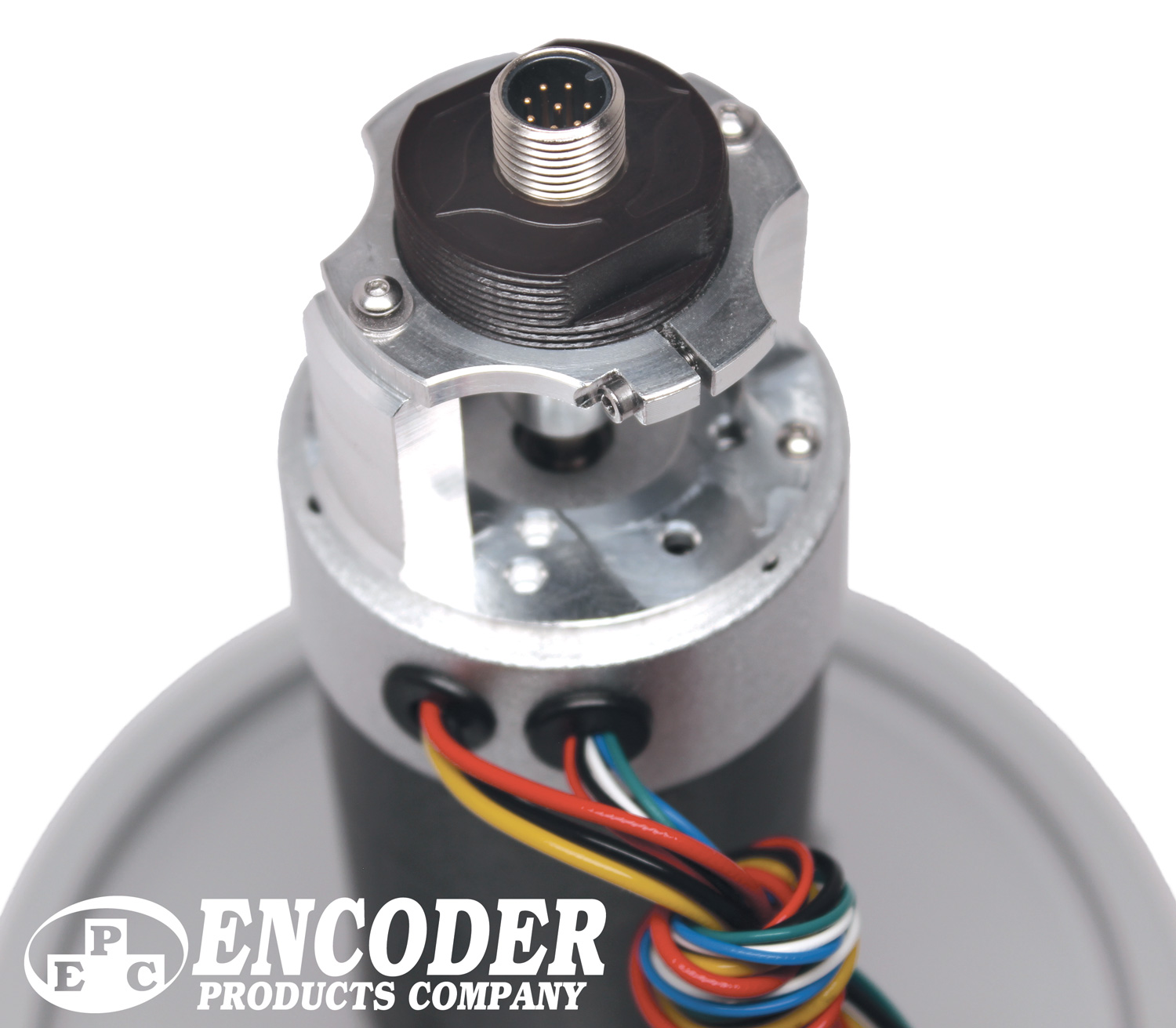

A threaded housing for quick and easy installation; sealing up to IP69K; resolution up to 1024 CPR; maximum frequency of 350 MHz; optional index channel with quadrature; four output types; 8-pin M12 connector

Applications include motor control and positioning

The Model 30MT is a versatile, cost-effective solution for non-contact, end-of-shaft rotary feedback in commercial, industrial and non-industrial applications. Some are servo or stepper motor control; mobile equipment speed and steering sensing; timber processing machinery; studio and stage equipment; solar panel positioning; vending machines; rotary valve positioning; punch presses; and robotics. More after the jump.

Shown here is the encoder installed on a motor.

Encoder Products Company (EPC) is a global leader in the design and manufacture of rotary encoders. EPC’s Accu-Coder encoders are used by OEM and MRO customers in nearly every industry. A vertically integrated 100,000 sq-ft facility in Idaho serves as the company’s headquarters.

Filed Under: Encoders (rotary) + resolvers, Motors • stepper, Motion Control Tips