With the introduction of FP 70, KNF further expands its series of smooth flow liquid pumps. This product line combines the low pulsation of a gear or centrifugal pump with the strengths and advantages of diaphragm pumps.

With the introduction of FP 70, KNF further expands its series of smooth flow liquid pumps. This product line combines the low pulsation of a gear or centrifugal pump with the strengths and advantages of diaphragm pumps.

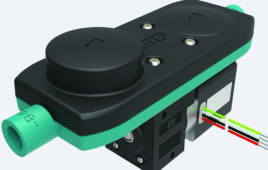

The KNF FP 70 delivers up to 850 ml/min while producing up to 29.4 PSIG (2 bar) pressure under continuous operation. Thanks to the patented 4-point valves, the KNF FP 70 is reliably self-priming, even at very low motor speeds. It also can safely run dry, handles liquid transfer gently and cleanly, and is available with chemically resistant flow path materials. Thanks to the integration of pulsation dampening technology, there is no need for additional pulsation dampening elements and tubing when using the KNF FP 70, thus reducing space requirements versus a pump-plus-damper approach.

The versatile FP 70 is available with a selection of motors to match the functionality and lifetime requirements of the application – from high-end BLDC to lower-end DC motors. Depending on the operating parameters, the high-end BLDC motor achieves a lifetime of more than 20,000 hours. Furthermore, the parameters of these motors can be customized at KNF to dial in the desired control behavior, performance characteristics and pump accuracy. Additional options include a selection of hydraulic connections and a variety of flow path materials, including an NSF food grade version. Combined with all these options is KNF’s ability to further optimize pumps to customer needs at any lot size.

The FP 70 is well suited for a wide range of applications including medical technology, inkjet, 3D printing and analytical instruments. It joins a growing line of KNF smooth flow liquid diaphragm pumps that now boasts a flow rate range spanning from 120 ml/min to 12.4 L/min.

The Benefits of Low-Pulse, Smooth Flow Pumps

Integrated low pulsation technology provides value in a variety of ways:

- Increased Pump Efficiency: the pressure resistance in a system’s tubing is reduced which significantly improves flow performance and accuracy. This can be a critical factor when small ID tubing is used. Smooth flow also increases the flow/power consumption ratio.

- Long Lifetime: Lower pressure peaks means less stress on all fluidic system components, resulting in longer component life and longer maintenance intervals.

- Space Savings: Integrating the damping system into the pump eliminates the need to include a separate damper, thus eliminating extra tubing and fittings (and two potential leak points!)

- Less Bubble Formation: The potential for bubble formation is reduced, thereby increasing the reliability of the system.

- Flow Sensor Cost Savings: A flow with low pressure peaks allows the use of common, lower cost flow sensors – such as impeller sensors – while keeping sufficient accuracy to regulate the flow rate. This offers the potential for cost savings, as flow sensors that can cope with large pressure variations can be quite expensive.

You may also like:

Filed Under: Pumps