Ranging from discrete product transport to bulk-material carriage, conveyor functions are as varied as the places in which they work. Engineers make conveyors meet specific applications by tailoring about a dozen conveyor design elements: belt or chain size, morphology and material; bases and support frames; controller, drive, and motor or motors; mode of belt or chain engagement with the drive; encoder, vision, and switch feedback; tracks, bumpers, and gates; and HMIs and plant-level IT integration.

Consider the warehouse-automation industry. Sorting and tracking tasks are paramount, but speed is often critical. Such applications need conveyors with servomotor functionality integrated with inspection stations fitted with machine vision. Or consider pharmaceutical manufacturing.

It’s grown to a trillion-dollar industry, even while standards such as the FDA’s Current Good Manufacturing Practice (CGMP) regulations are more stringent than ever. Here, conveyors must have all the functions of those for warehouse-automation, plus need to be stainless and aluminum, posing no risk of contamination, while quickly and cleanly transporting expensive pharmaceutical products to and from stations for bottle filling, pill compressing, sorting and inspection.

In the same way, the manufacture of medical devices must adhere to FDA regulations that dictate equipment-sterilization schedules and methods. Here, only conveyors withstanding regular harsh cleaning last.

Packaging application:

Conveyors support coordinated robot tasks

Mounting coin proof sets into hobbyist commemorative cases sounds easy, but it’s challenging when the application calls for precisely placing several thousand coins on moving inserts every day. This was a challenge engineers at Farason Corp. recently solved with conveyors from Dorner Manufacturing and vision-guided robots.

Farason designs and builds custom machinery for assembly, manufacturing and packaging processes (mostly in cosmetics, food and confections, medical, pharmaceutical and manufacturing industries).

For the coin-setting application, a system picks and orients coins in case inserts, then encloses the inserts with top and bottom lenses, said Joe Hurley, president, Farason.

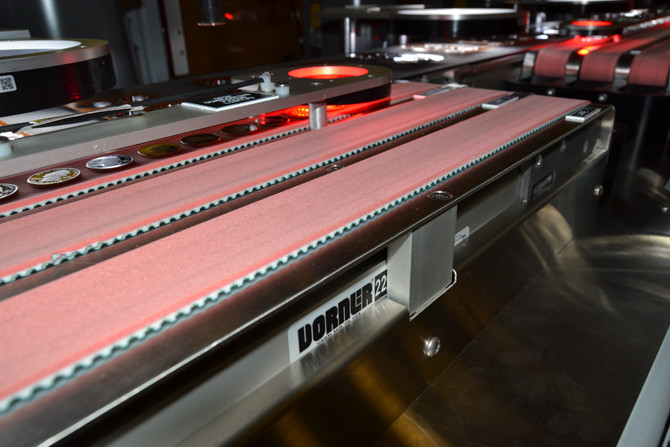

The automated system uses 13 vision-guided robots and 22 Dorner conveyors purchased from Stokes Material Handling Systems. First coins enter the machine in trays for indexing. Six Dorner 2200 Series conveyors feed stacks of trays containing the different coins to unloading robots.

These robots remove rows of coins from their respective trays and place them onto one of six servo-driven Dorner timing-belt conveyors. Each 2-in.-wide conveyor indexes coins downstream to where a camera logs the coins’ rotational orientation. A placing robot tends each conveyor and takes coins and places them (properly oriented) into coin wells. After depleting a tray, these robots then put empties on a Dorner 2200 Series conveyor for transfer out of the machine.

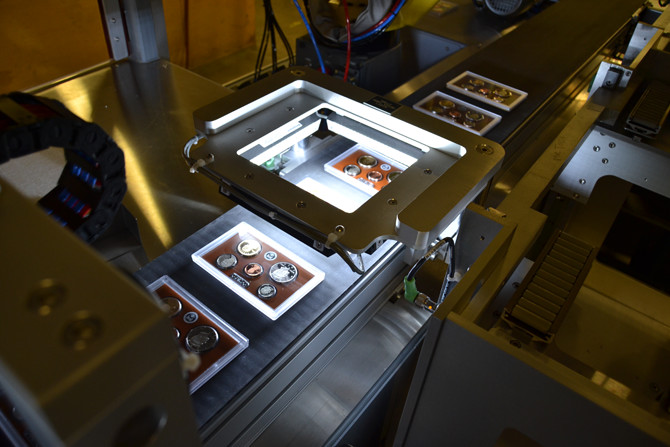

Upstream robots pick coin inserts from a stack, present them to a camera (which checks for smudges, scratches and other imperfections) and then place them onto a 10-in.-wide Dorner 3200 Series conveyor. This conveyor transfers the coin inserts past six coin-placing robots.

Next, a flipper robot puts completed coin inserts into a device that overturns the inserts 180° for downstream assembly.

Top and bottom cameras inspect the insert to ensure all coins are present and properly orientated. Inserts that pass inspection go to a robot that picks top lenses from a stack, presents them to the camera for inspection, and then places them down onto a Dorner 3200 Series conveyor. The flipper robot puts the inserts into the top lenses; then the conveyor takes the partial assemblies to a station where (after another inspection) a robot presses the cases’ bottom lenses in place.  Then the conveyor takes the final packages to a trolley-loading robot that gathers them in three-up operation for shipment preparation.

Then the conveyor takes the final packages to a trolley-loading robot that gathers them in three-up operation for shipment preparation.

All other Farason-built coin-picking systems use Dorner conveyors. This latest design took about a year from initial specification to delivery and commissioning in April.

![]()

Filed Under: Motion Control Tips