By Paul Denman • Applications engineer and business development Nippon Pulse America

Today most linear-motion designs execute their strokes with actuators based on stepper motors or brushless dc (BLDC) servo motors. Such designs have an inherent complexity due to the fact that the motors and its gearing and encoder must essentially hang off the machine design and out of the needed motion space.

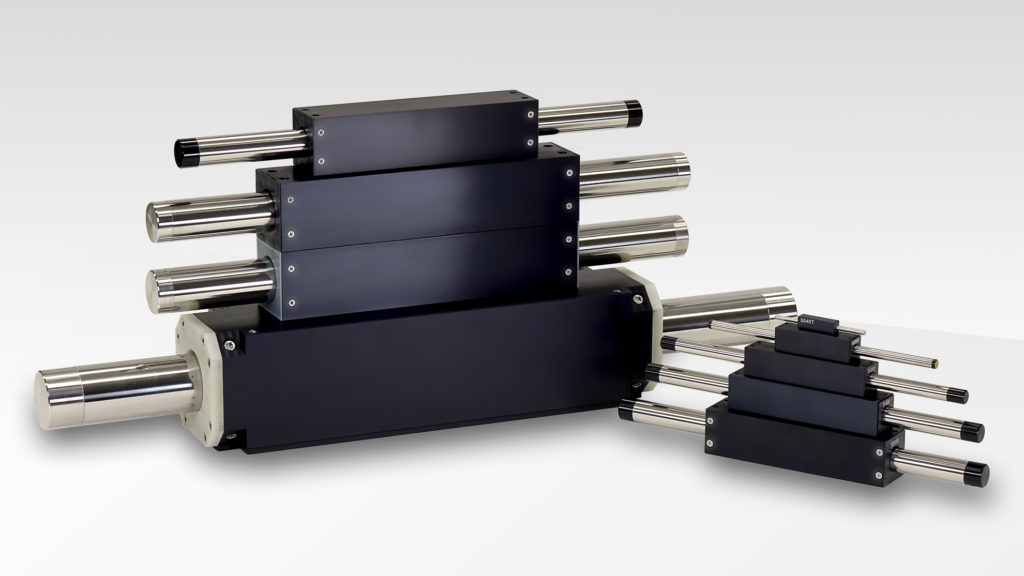

Nippon Pulse America can supply linear shaft motors up to 14 feet long. Applications of these higher-power shaft motors are expanding as engineers discover their availability and use.

One fast-growing trend is migration towards linear shaft motors — a more compact solution that only requires space for an encoder and linear bearing inside the motion space.

Linear shaft motor adoption has grown faster in the last decade due to the increased performance of their magnets — which in turn has made them more power dense than early-generation versions. How do these linear motors work? In short, the motor’s magnetic shaft consists of a hollow nonferrous stainless-steel tube housing a stack of doughnut-shaped magnets. Because the forcer coils wrap a full 360° around the shaft’s magnetics field, these linear motors deliver 40% more power than competitive offerings. What’s more, one shaft can accommodate several forcers — for even more compact and flexible solutions.

Some manufacturers of linear shaft motors even stack the magnets with their poles north to north and south to south (in a rather advanced assembly process) for even higher force and efficiency. That results in linear motors with exceptionally high force capabilities. This design arrangement and the fact that magnets have become increasingly strong mean that some linear shaft motors can output more than 6,000 N.

One last benefit of linear shaft motors is that they exhibit zero cogging so maintain high accuracies — even up to the accuracy of the selected encoder. Resolutions better than 10 µm are possible without increased motor price.

Filed Under: Linear Motion Tips