FarmWise is an AgTech company that’s pushing the boundaries of automation in agriculture by harnessing the power of computer vision and artificial intelligence to revolutionize farming operations. Their flagship product, the Vulcan precision weeding implement, is designed to optimize weed control management on vegetable farms in California, which have been slow to automate due to…

PBC Linear MTB series now includes MTB 105 belt-driven actuator

PBC Linear, a Pacific Bearing Company and a global leader in linear motion solutions, is pleased to announce it has expanded its MTB Series of Belt Driven Linear Actuators line with the MTB 105. Engineered with precision and versatility in mind, the MTB 105 is specifically designed to integrate into multi-axis medium- to large-sized Cartesian […]

Design tips for linear motion systems in washdown applications

Designing linear motion systems for washdown applications requires careful component selection to solve problems associated with contamination as well as liquid and chemical interactions. When food and pharmaceutical contact is a factor, it’s often necessary to wash or sterilize processing, packaging, handling, and automation equipment. When specifying components for such environments, design engineers must not…

PBC Linear receives Universal Robots+ partner certification for its applied cobotics cobot feeder

PBC Linear (Pacific Bearing Company), a linear motion solutions provider, announces that its Applied Cobotics Cobot Feeder, a CNC machine feeding application kit that delivers and stages parts to be placed into a machining process, has received Universal Robots+ (UR+) partner certification from Universal Robots (UR). PBC Linear’s Applied Cobotics Cobot Feeder includes a base […]

The latest developments in fast food automation

The fast-food industry is all about tasty food at low prices with cheerful customer service — all delivered fast. But with labor shortages and supply chain issues still plaguing the economy, how can businesses compete and survive? Fast-food restaurants across the globe are pondering ways to automate certain tasks or entire assembly lines to provide continuous service […]

Trends in digital manufacturing

The convergence of software, cloud computing, and additive manufacturing (3D printing) technologies has given manufacturers the ability to cost-effectively supply millions, thousands, or dozens of a given workpiece — and even batch sizes down to one. It’s no wonder that worldwide, batch sizes have in fact shrunk ‚ catering to increased demand for customized products […]

Top trends in linear motion technology: Part 2 of 2

For the annual Design World Trends issue, we asked industry experts to share their insights into linear-motion trends. Here’s more of what they had to say on linear actuators, linear guides, and stages. Meet the experts Dave Walden | Applications engineer • PBC Linear Eric Rice | Product market manager — electric automation • Festo Samuel Orozco | […]

Top trends in linear motion technology: Part 1 of 2

We recently asked several industry experts about trends they’re seeing in the design and use of linear actuators, linear guides, and stages. Here’s what those experts had to say. Meet the experts Saurabh Khetan | Product line manager — Leadscrews • Thomson Industries Inc. Justin Lackey | Product manager — Systems • Bosch Rexroth Kelly Walden | V.P. […]

Top industrial connectivity and digital-transformation trends: Part 1 of 2

Discrete automation’s edge devices include actuators, sensors, and connectivity components such as gateways and motor-mounted controllers. Many of these components feature computational capabilities to minimize data bandwidth and latency issues associated with legacy versions of centralized control. Their installation at the furthest reaches of automated equipment means their processing power is situated to filter and…

PBC Linear expands Applied Cobotics product line with Cobot Feeder

PBC Linear, a Pacific Bearing Company, continues to strengthen its Applied Cobotics brand with the latest product offering, the Cobot Feeder. This essential automation tool will help small- to medium-sized companies boost their robot production without significant increases in labor, and ultimately see a higher return on their investments. Cobot Feeder The Cobot Feeder from…

PBC Linear launches miniature metric ball screw assemblies

PBC Linear, a Pacific Bearing Company and a global leader in linear motion solutions, has expanded its comprehensive portfolio to include Miniature Metric Ball Screw Assemblies. Building on the success of their lead screw technology, this combination of precision-rolled screw and compact nut is driving exceptional performance from an economical package. Manufacturers of sophisticated laboratory equipment,…

Five ways to drive ROI from personnel and cobot investments

In this article, we detail how assembly, packaging, and machine-tool OEMs can keep senior plant personnel in charge of the most demanding and intricate tasks — and relegate everything else to pre-programmed work routines and automated workcells. Such approaches make copious use of cobots and augmented reality (AR) tools. By Tim LeCrone • Director of […]

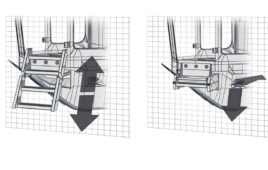

Linear bearings set the stage in entertainment industry application

A renowned entertainment company was tasked with creating a complex and movable staging apparatus for an upcoming major performing artist’s tour. To build the stage, they needed a rugged linear bearing system that included a large quantity of heavy load-bearing rail. Along with materials, flexibility was also essential to the design. Therefore, having consistent products…

Consistent linear motion systems with the PBC Linear Uni-Guide

The white paper, Consistent Linear Motion with Uni-Guide Linear Systems: Eliminate Artifact Lines with Consistent Linear Motion examines the primary need for a linear guidance system that provides consistent repeatable performance. This is especially important in the use of large format digital image scanning and has broadened into many fields such as architectural drawings, mapping,…

Linear Motion Design for Washdown Applications – From PBC Linear

A “washdown environment” is one that utilizes either by hand or by automatic means, cleaning with water, chemicals, or a mixture of these. This washdown process can be as simple as a cloth and bucket, use of a hose to spray clean, or it can be under sophisticated high pressure and controlled systems. The design…

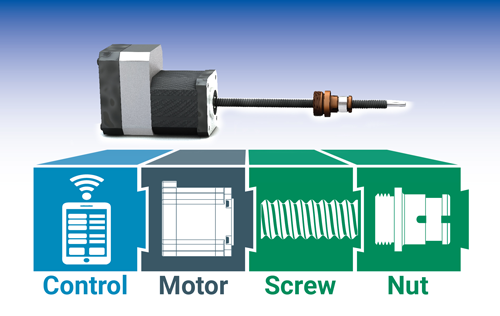

How it’s made — lead screw assemblies from PBC Linear

As today’s technological capabilities have become more sophisticated, the working parts within machine systems have increasingly required greater performance. That need for more precise linear motion has driven PBC Linear to pinpoint substantial resources along each step of its engineering and manufacturing of lead screws, and simultaneously employ quality metrology processes. The result is an…

Linear motion trends in slides: Robotics and mobile designs lead the charge

Demand for simple-to-install and pre-integrated linear-slide systems continues unabated … especially in applications only recently automated. Here’s the perspective of Matt Mowry, North American market manager for drylin products at igus: “We’ve supplied fully assembled and customized linear-slide tables … complete with motors and accessories. We’ve also supplied custom-extruded linear profiles and bearing liners to […]

Electric actuators displace other motion options — including manual designs: A Motion Trends report

Today, electric actuators are easier than ever to specify and install. Value-add services from component suppliers as well as application-specific actuator product lines (especially for battery-powered designs in mobile equipment and consumer use) eliminate many integration tasks for OEMs and end users. These are trends supported in part by a movement Design World has tracked […]

Webinar: Advancements in Integrated Motor Screw Technology

This on demand webinar was recorded on Tuesday, June 27th. Today’s Linear Motion Applications are requiring significant advances in dynamic performance – including speed, accuracy, and velocity smoothness. This all must be achieved while satisfying the market demands for enhanced reliability, reduced size, and lower cost. To accomplish these goals, a system level approach is…

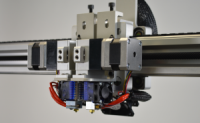

Webinar: How Mechatronics is Taking Additive Manufacturing to the Next Level

This webinar was originally broadcast on Wednesday, December 14, 2016 Watch On Demand: Additive manufacturing has achieved mission-critical levels. Mechatronics is responding to market demands that must be addressed for widespread adoption of industrial 3D printing. During this webinar, you will learn: What market demands are driving the 3D printing growth? How to…

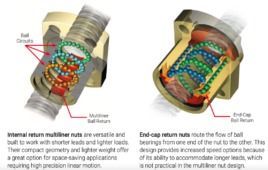

A guide to plain bearing materials in linear motion applications

One of the benefits of plain linear bearings is their simplicity. Especially when compared to recirculating bearings, plain bearings are easy to specify, install, maintain, and replace. But don’t let that simplicity fool you. Choosing the wrong bearing, or more specifically, the wrong bearing material, can result in poor performance, degradation of the bearing, or […]

Golf-club washer uses linear-motion actuators to transport wash nozzles

Soon, you could see a new station called a Riveer TourSpin Club Washer cleaning dirty irons and hybrids at a golf course or country club near you — with the…

New video — Internet of Things (IoT) in linear motion

The latest trend in machinery design is to take advantage of the Internet of Things (IoT) and its many benefits. Internet connected “smart” technology is found in connectivity,…

Maintenance free plain bearings

PBC Linear’s Simplicity linear plain bearings, equipped with a Frelon liner, outfits your design with the advantage to last longer and reduce unnecessary replacement costs. By designing the…

The post Maintenance free plain bearings appeared first on Bearing Tips.

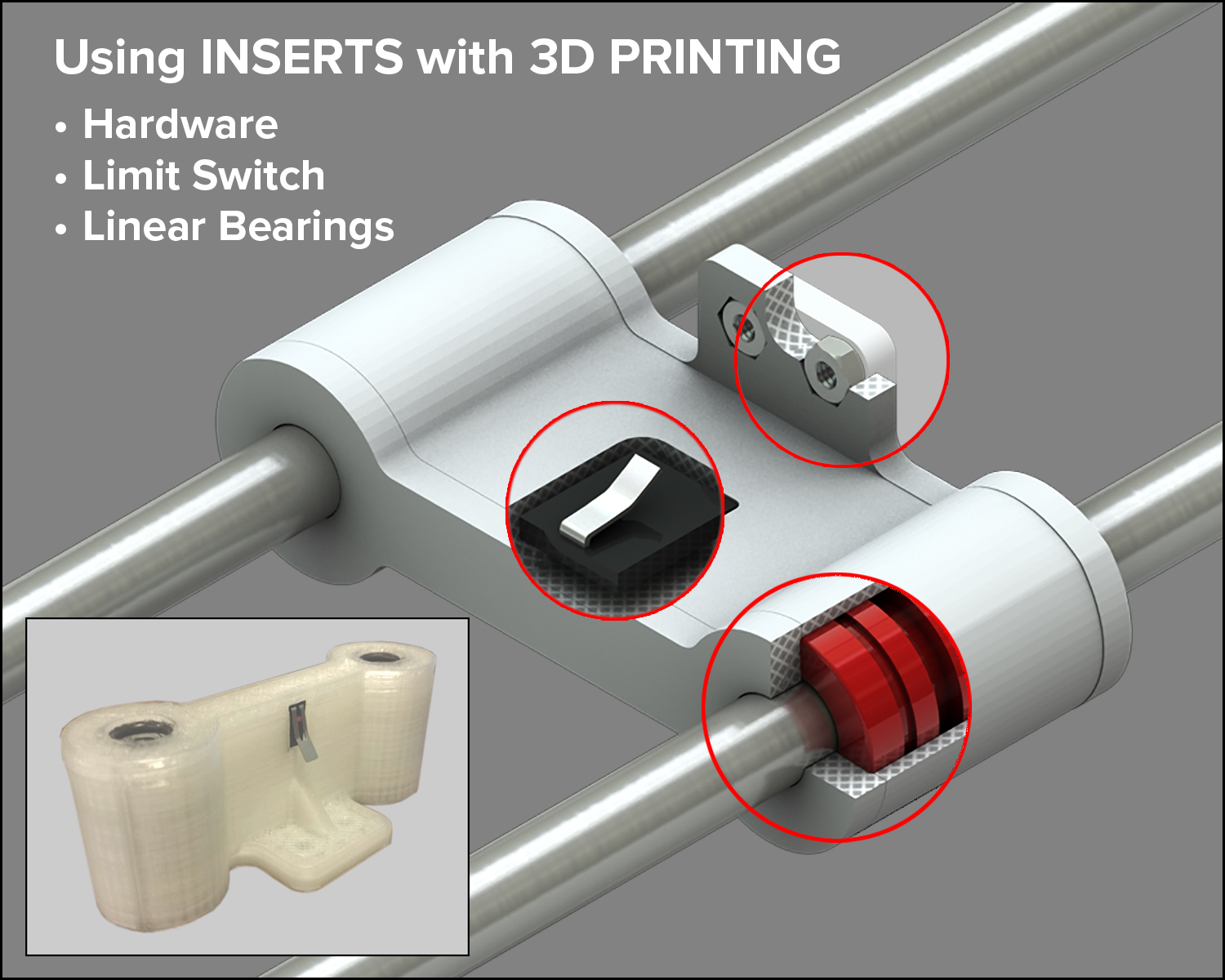

Expanded 3D Printing Capabilities—Going Beyond Prototyping

Fill out the form the watch this exclusive webinar from 3D Platform. Advanced processes in 3D printing, such as inserts, core modeling and multiple materials, can expand the capabilities of a 3D printer. Incorporating non-printed elements, such as fasteners, electronics, switches, sensors, or even metal sub-structures, into a printed part expands the spectrum of usability—resulting…