Micro-Mold®

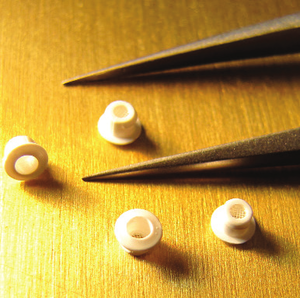

These minute parts are often measured in microns and are no bigger than 0.5 cubic inches; they typically weigh less than a gram. In addition to their size, these parts have very tight tolerances and must be molded efficiently and precisely – time and time again.

Accumold builds specialized molding machines for this unique capability. The machines are engineered to handle volumes from prototypes to millions per year while maintaining consistent, precise tolerances that are unique in the industry. The specialized tooling and molding for micro-sized components are only available at Accumold.

Small Parts

Not every micro-molded application requires microscopic parts, but many require demanding geometry and tight tolerances on a slightly larger scale. Micro-features – incorporating very small features on a normal-sized part up to about 3 inches in diameter – are another of Accumold’s capabilities.

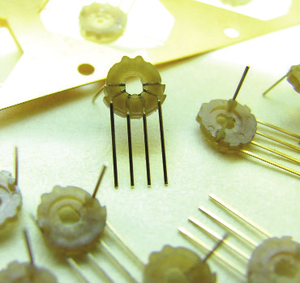

Lead Frame / Insert Molding

Insert micro-molding involves molding in or around a wide variety of materials such as plastic, ceramic, glass, fabrics, film or foil. This type of over-molding can be achieved on either the Micro-Mold® or Small Mold platforms with the same high-precision output. The process can be operator loaded or our Automation Team can build a custom loading system for high-volume applications.

Facilities

Accumold is an ISO 13485, 9001 and 14001 certified company with a state of-the-art, 130,000 square foot production plant. The Accumold facilities are located near Des Moines, IA, in the heart of the Midwest. The building is climate controlled and includes six 100K clean rooms and three 10K clean rooms for micro-electronics and medical applications.

Accumold began in a rented garage in 1985. Our primary focus was and still is on very small micro-sized plastic parts and components that other companies can’t produce. The original Micro-Molder® was designed to help manufacture parts with minimal waste and short cycle times for electronic component manufacturing. Although there have been many innovations over the years the basic principals have remained the same and so has our commitment to micro-injection molding technologies.

Today the company now focuses on industries that require fast turn around and complex parts for high tech industries such as Micro Electronics, Micro Optics, and Medical, as well as new emerging markets and technologies.

Our founders established high standards of quality when the company began. These standards still exist today! We still have many of the original customers that entrusted their most valuable parts production to us. We believe this is due to our professional management staff, expert tool makers, and our top notch production team.